Coal mining machine intelligence control system based on ARM microcontroller

A technology of an intelligent control system and a microcontroller, applied in the field of shearer control, can solve the problems of not being able to control the operating parameters of the shearer in time, working with diseases of the shearer, and high labor intensity, so as to achieve remote monitoring and fault monitoring. Diagnosis function and memory cutting function, which are beneficial to installation and maintenance, and ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

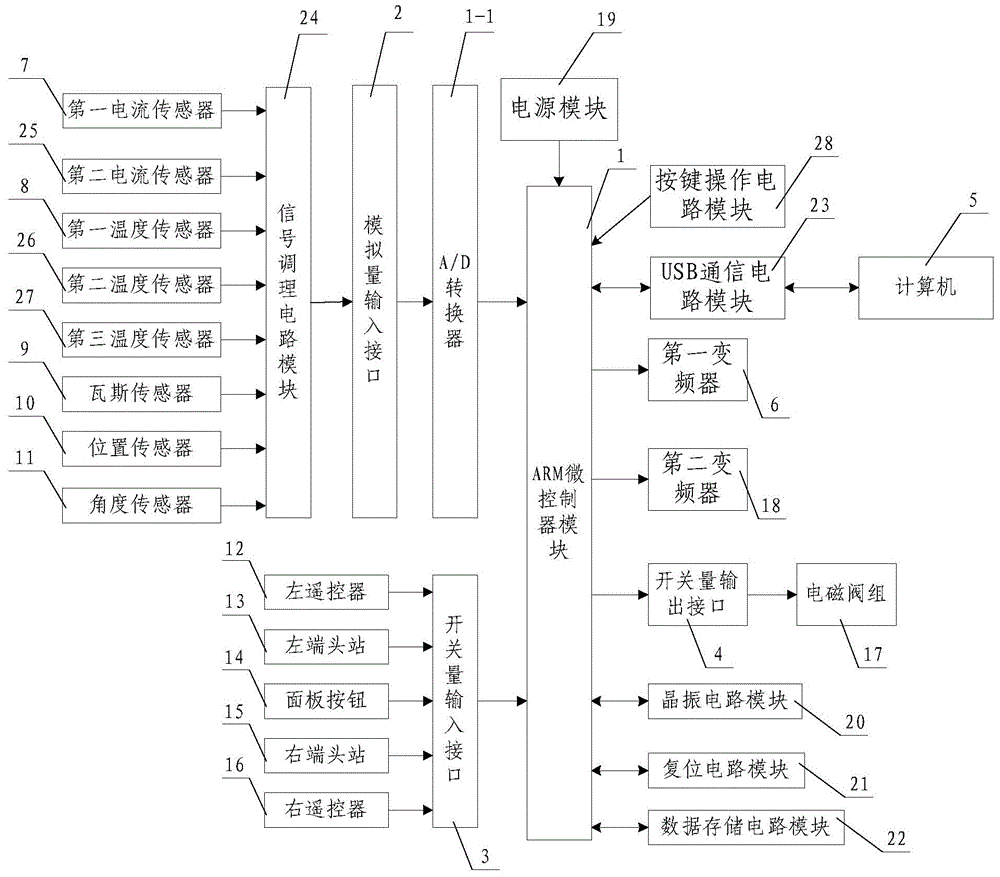

[0028] Such as figure 1 As shown, the present invention includes the ARM microcontroller module 1 that is integrated with the A / D converter 1-1 and the power supply module 19 that supplies power to each power module in the system, and is connected with the ARM microcontroller module 1. A crystal oscillator circuit module 20, a reset circuit module 21, a data storage circuit module 22 for data storage and a USB communication circuit module 23 for communicating with the computer 5, the input terminal of the A / D converter 1-1 is connected There is an analog input interface 2, the input terminal of the analog input interface 2 is connected with a signal conditioning circuit module 24 for amplifying and filtering the signal, and the input terminal of the signal conditioning circuit module 24 is connected with a signal conditioning circuit module 24 for cutting The first current sensor 7 for detecting the current of the motor, the second current sensor 25 for detecting the current o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com