A kind of manufacturing method of ultraviolet led curing optical system

A technology of optical system and production method, which is applied in the directions of instruments, calculations, and electrical digital data processing, etc., can solve the problems of low energy utilization rate, high light intensity in the intermediate curing area, and decreased uniformity, so as to meet the requirements of ultraviolet curing and energy utilization rate. High, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

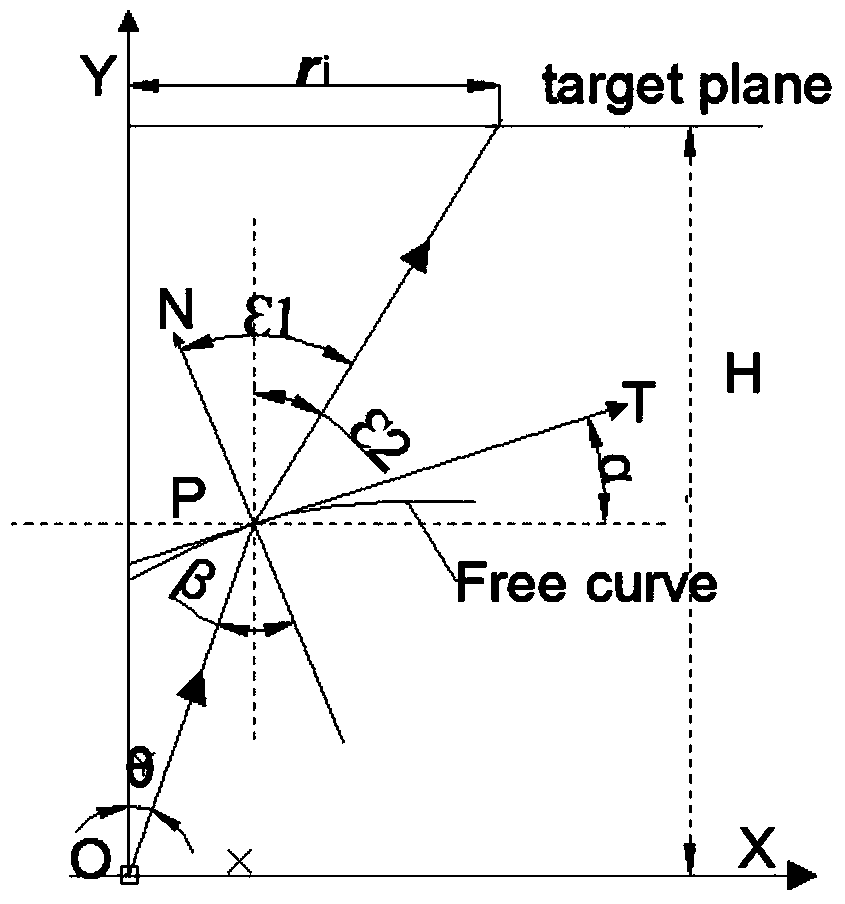

[0057] Such as figure 1 Shown, a kind of fabrication method of ultraviolet LED curing optical system comprises the following steps:

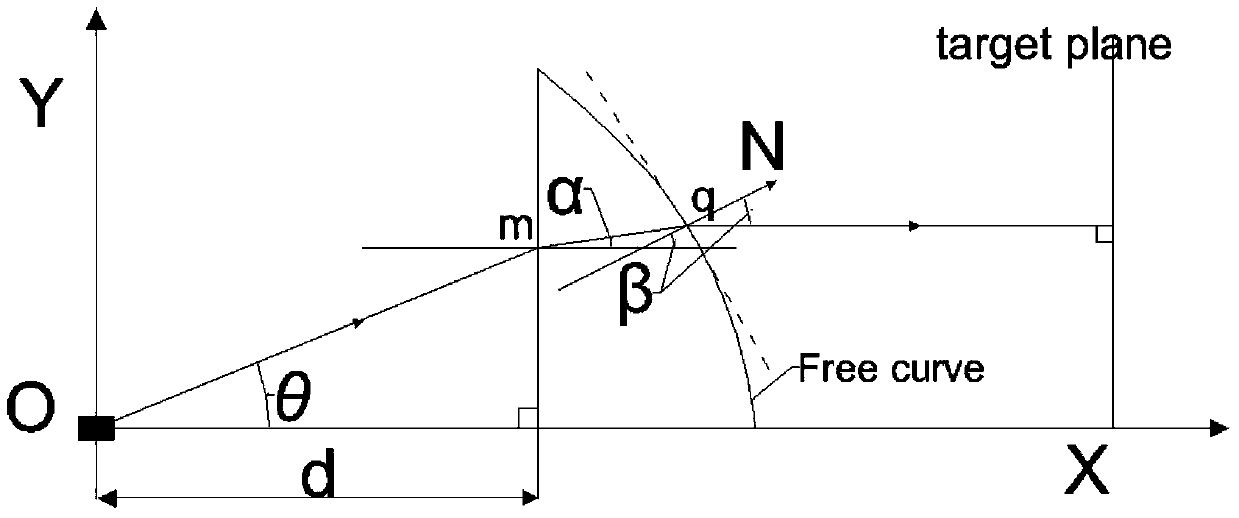

[0058] Step 1: Establish a plane coordinate system with the coordinate origin O(0,0), including the X-axis and Y-axis, take the coordinate origin O as the ultraviolet LED light source, and deduce the coordinate iteration relationship of the following two free curve discrete points;

[0059] a) The making of the outline of the free-form surface of the outer lens;

[0060] Such as figure 1 As shown, the angle between the light emitted by the light source O and the Y axis is θ, and the angle between the normal line at the intersection of the outgoing light and the free curve of the outer lens and the outgoing light is ε1, when θ is θ i , the light emitted from point O of the light source passes through the i-th point p on the free curve of the outer lens i (x i ,y i ) reaches the receiving screen after refraction, θ i and θ i+1 respectively ...

Embodiment 2

[0094] A method for manufacturing an ultraviolet LED curing optical system, comprising the following steps:

[0095] Step a: Use the LED curing line light source lens model described in Step 3 of Example 1, with the same material and size as Example 1;

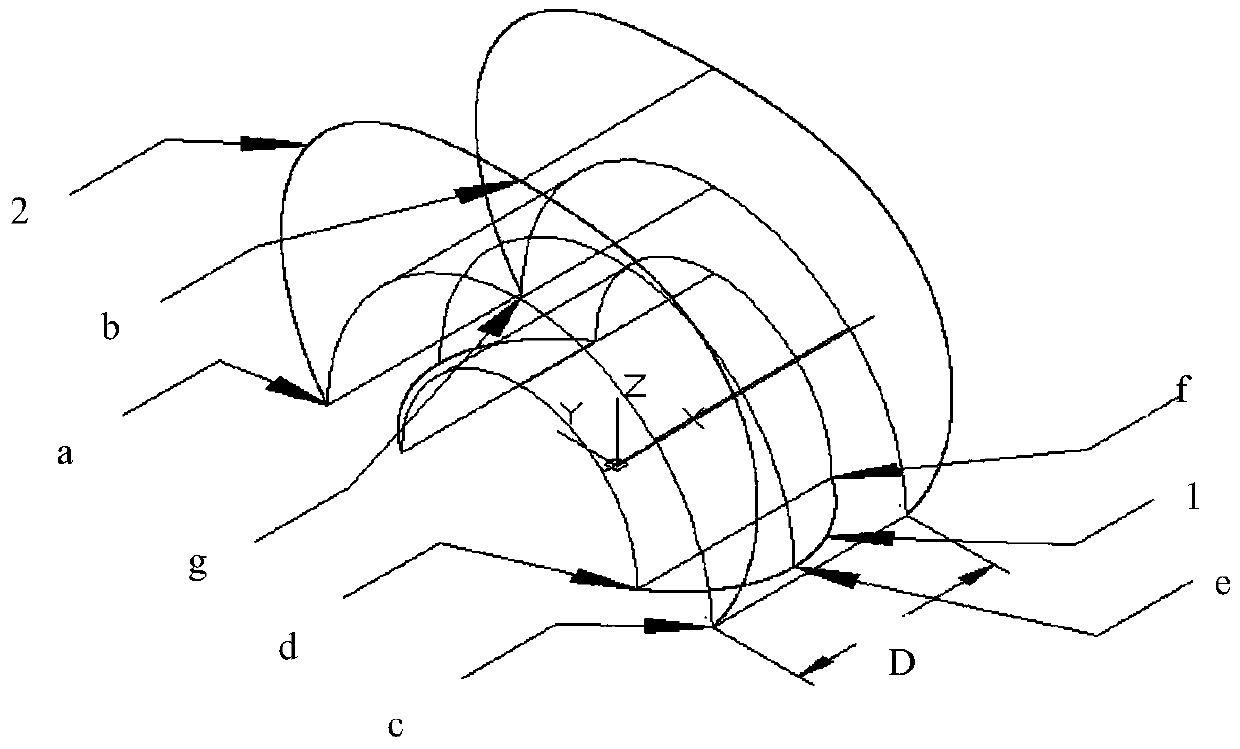

[0096] Step b: Arrange the LED curing line light source lens models in the six steps a in an arc-shaped integrated arrangement with an included angle θ of 2.5° to obtain an ultraviolet LED curing surface light source optical system that produces a large rectangular spot. The physical model is as follows Figure 4 shown, and then imported into the TracePro optical simulation software to verify and analyze the built model. The working distance is 50mm, Figure 6a and 6b Respectively, the illumination distribution spot diagram and curve diagram on the receiving plane. Depend on Figure 6a It can be obtained that the light is basically controlled in a long rectangular spot with a length of about 120 and a width of about 100mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com