A cooling device for a power battery

A heat dissipation device and power battery technology, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of overweight heat dissipation fins, bulky volume, complex process, etc., achieve good heat dissipation effect, less material consumption, The effect of enhancing the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing.

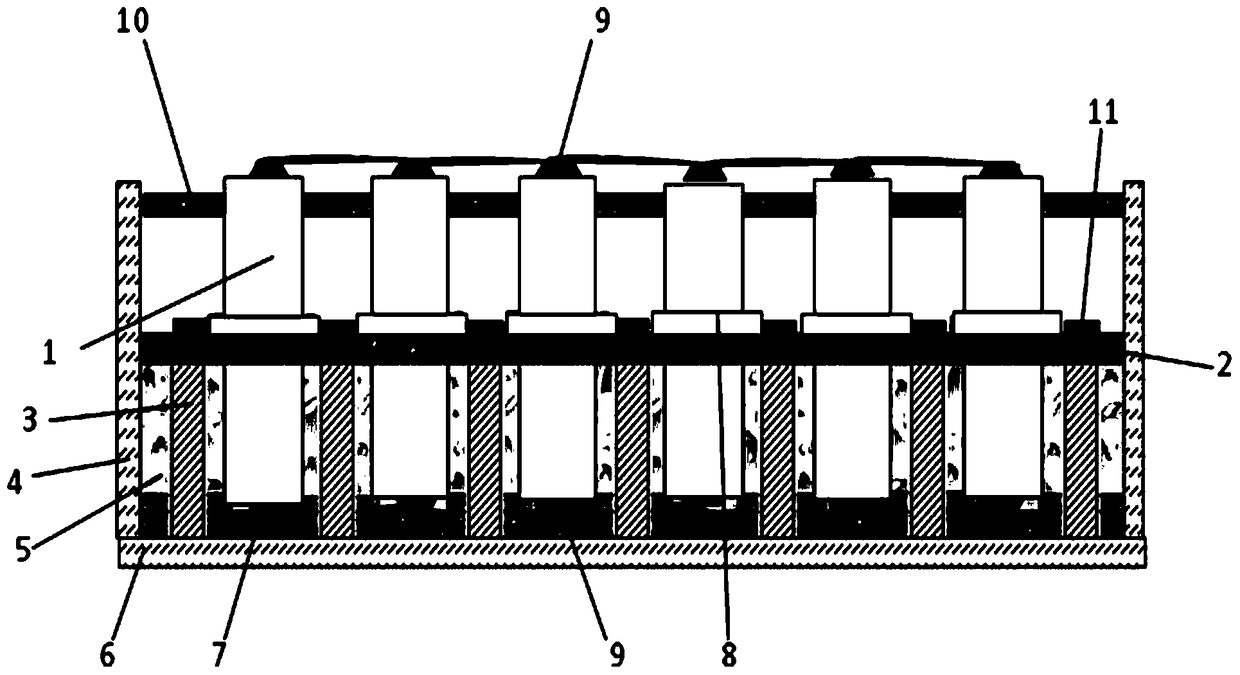

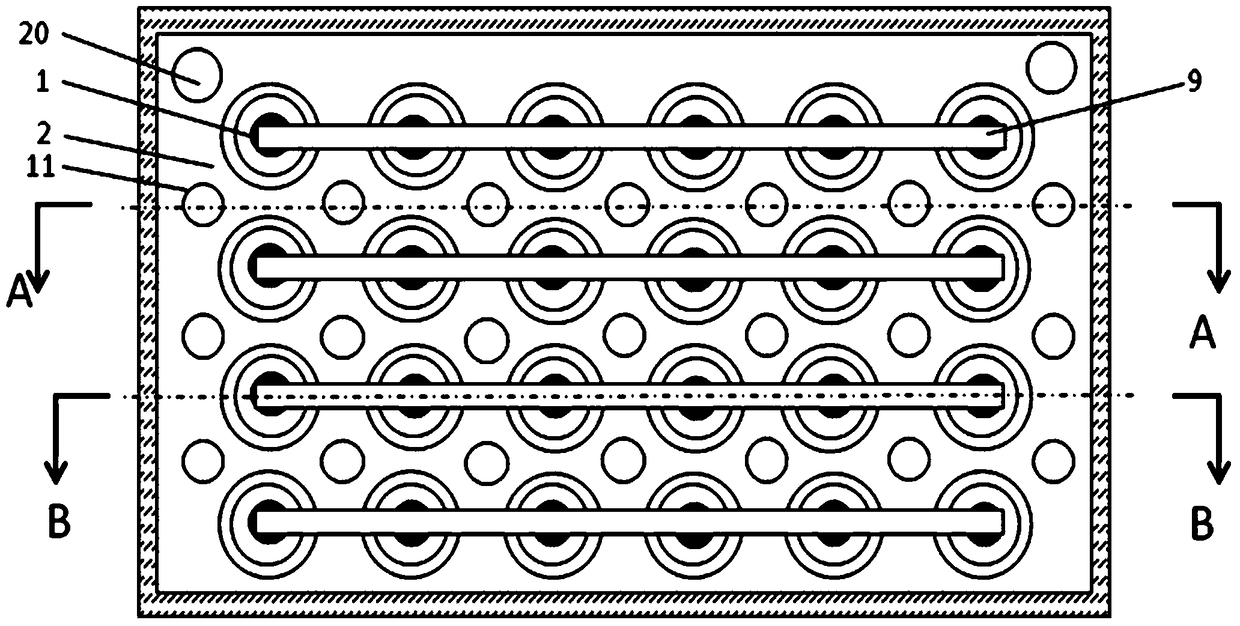

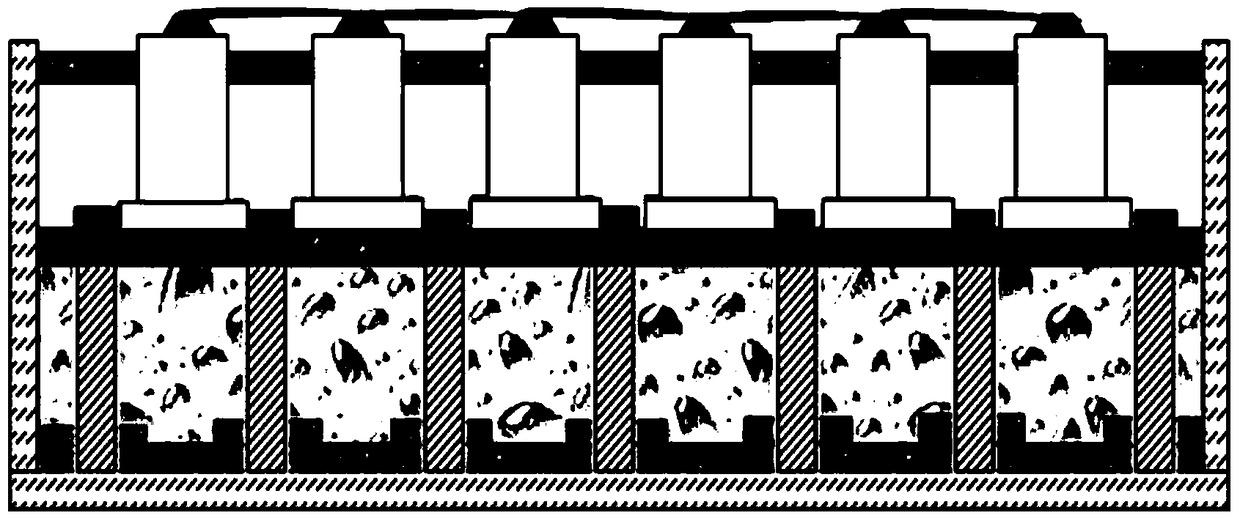

[0046] like Figure 1~5 As shown, several cylindrical batteries 1 are vertically arranged at intervals in the battery pack box with the opening upward, and the batteries 1 may be in the shape of a square column, a cylinder, or an aluminum-plastic film soft bag, etc. Near the top of the battery 1, an upper insulating plate 10 is arranged in the battery pack box, the upper insulating positioning plate 10 is tightly sleeved on the battery 1, and the lower insulating plate 7 is cushioned between the bottom of the battery 1 and the bottom plate 6 of the battery pack box.

[0047] A thermal diffusion plate 2 is arranged between the upper insulating positioning plate 10 and the buffer lower insulating plate 7. The thermal diffusion plate 2 is a metal plate with high thermal conductivity such as aluminum, copper, titanium, iron, etc., and the thickness is 0.3-3mm. 2 The outer surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com