Bus-based automotive led matrix headlight controller

A controller and LED driver technology, which is applied in the direction of headlights, vehicle parts, lighting and heating equipment, etc., can solve the problems of high layout and wiring requirements, reduce thermal resistance, multiple lamp bead positions, etc., and achieve EMI performance optimization, reduce Small heat dissipation thermal resistance, the effect of improving signal immunity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

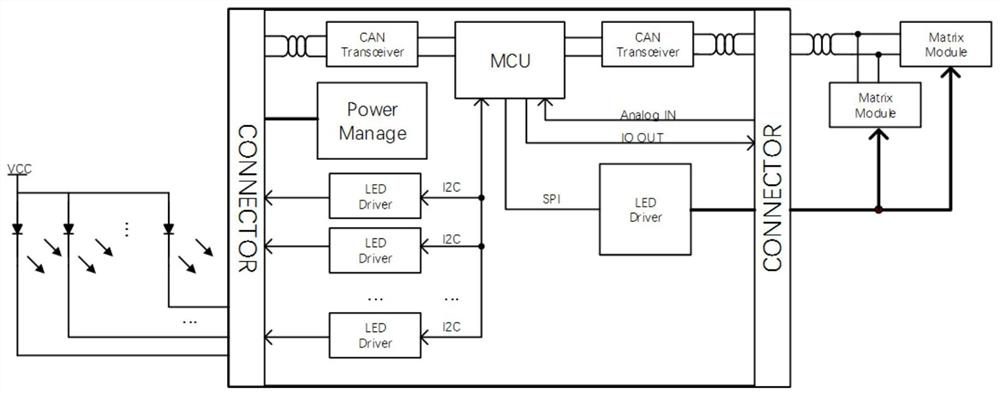

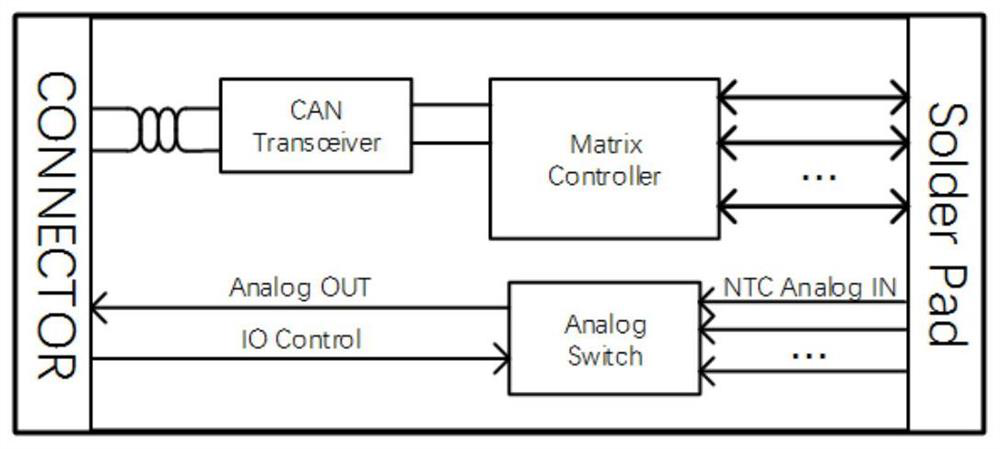

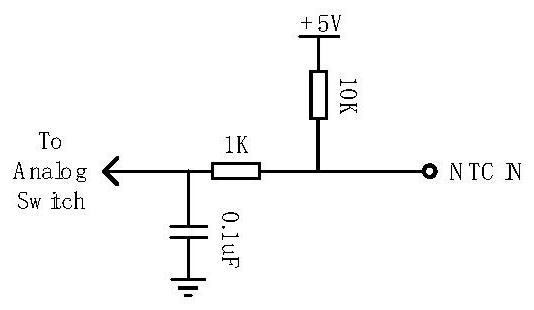

[0021] A bus-based automotive LED matrix headlight controller (see attached figure 1 To attach Figure 5 ), including the main control unit and the matrix control module for controlling the matrix control module, collecting temperature information and error information, controlling the turning light and communicating with the outside, the matrix control module includes the main control board, FPC flexible board and lamp beads board, the main control board uses FR4 base material, the lamp bead board uses aluminum substrate, the power and signal of the lamp bead board and the main control board are transmitted through the FPC flexible board, and the FPC flexible board is connected to the lamp bead board and the main control board by welding plate. The main control unit includes an interface circuit, an MCU, a CAN bus receiver, a low-power LED driver circuit, a matrix LED driver circuit, and a power management unit. The low-power LED driver circuit is connected to the MCU throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com