Fixed flange assembly and construction method for fixed flange assembly

A technology for fixing flanges and assemblies, which is applied to cable accessories, cable installation, equipment for connecting/terminating cables, etc. It can solve the problems of increasing construction time, restricting the correct fixing of armored wires, and reducing grounding efficiency, etc., to achieve The effect of saving the time required for winding, stabilizing the power supply, and increasing the grounding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

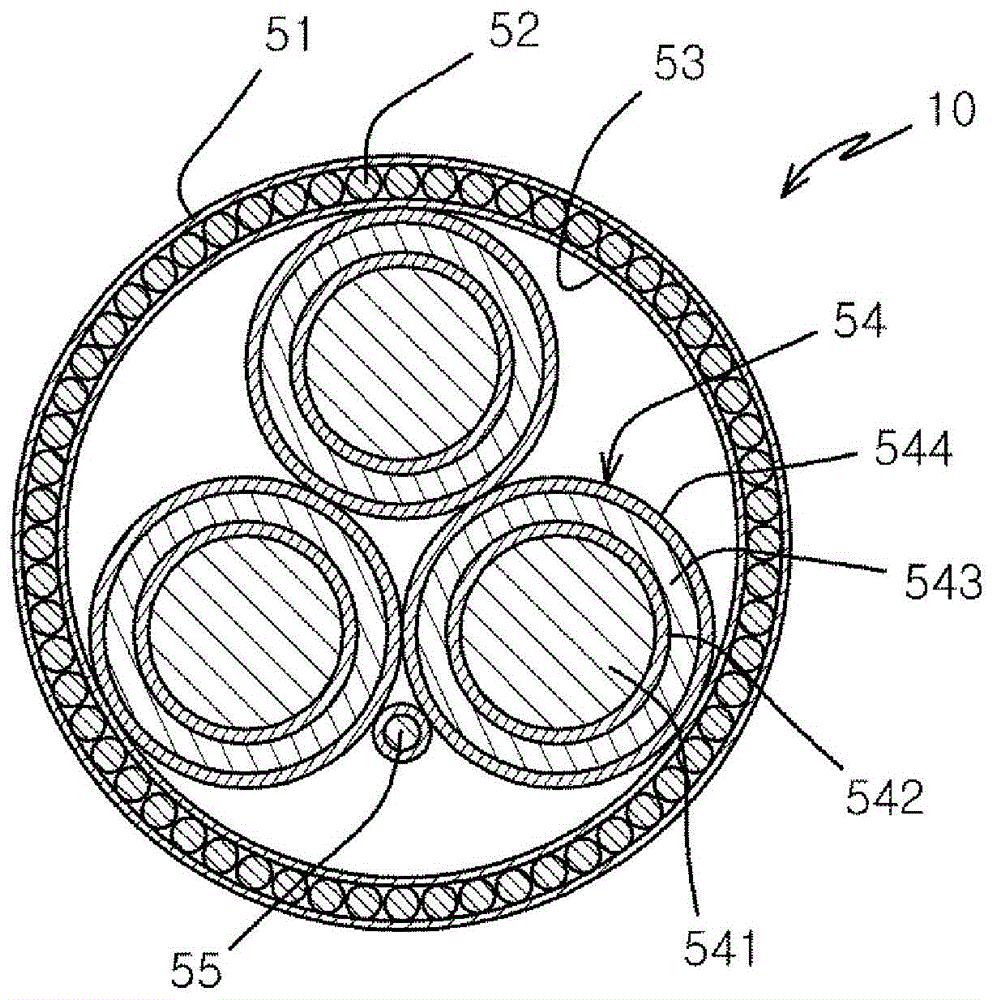

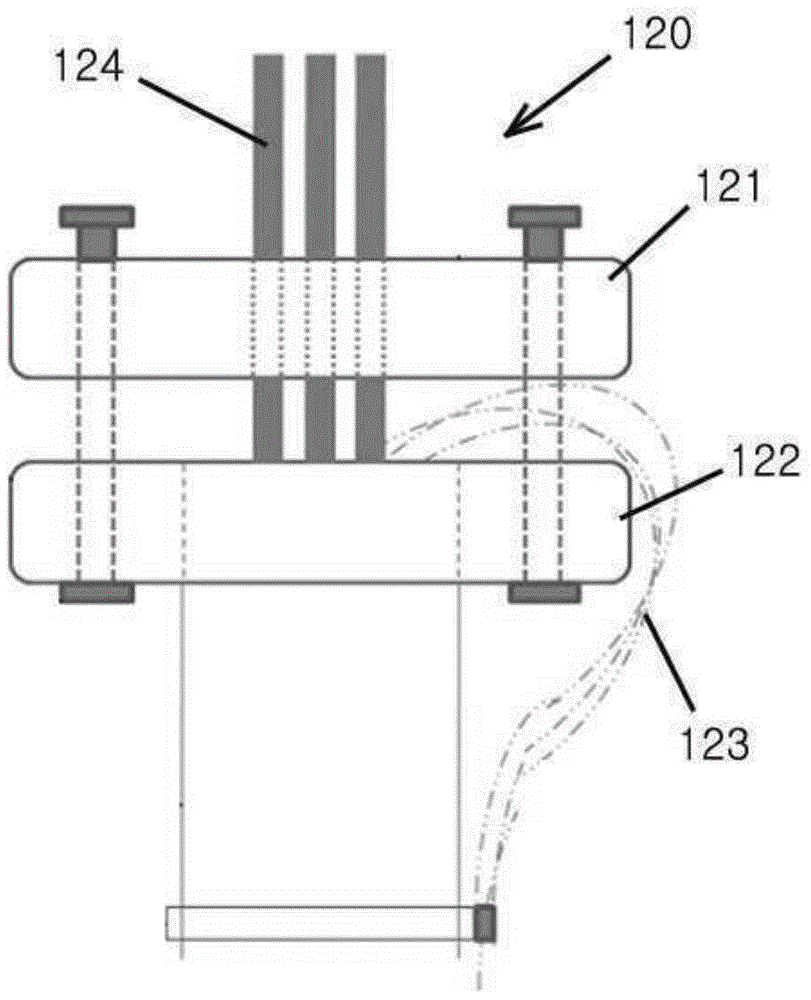

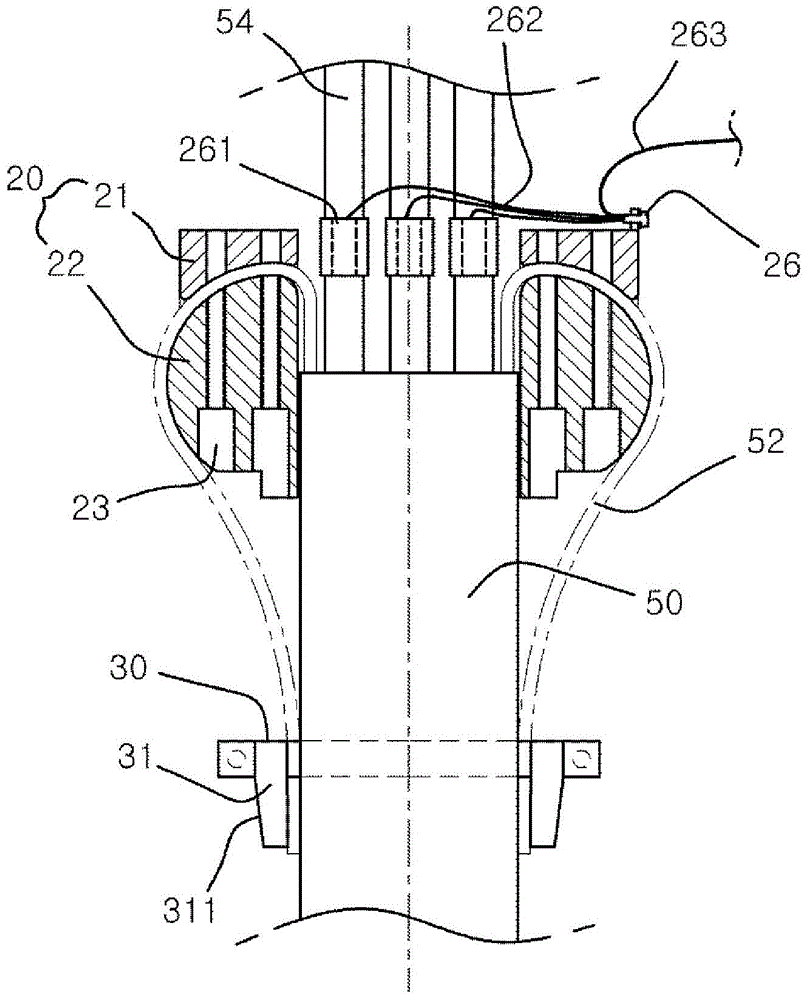

[0041] The fixed flange assembly of the present invention has the following features: the submarine power cable that forms the power supply and communication connection between the land or sea structures through the seabed is fixed on the land or sea structures, and the power generation on the seabed power cables The grounding current is connected to the fixed flange of the external ground and the fixed flange assembly of the junction box with the built-in fixed flange; The hole passes through the submarine power cable; between the upper flange and the lower flange, the sheath of the submarine power cable is peeled off to expose a certain length, and after connecting with the cut armored wire, it communicates and accepts the grounding current; the upper flange and the lower flange One side of the lower flange is connected with the grounding bolt combined with the external grounding wire, and the grounding current is transmitted and received from the three-phase cable of the arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com