Piezoelectric single wafer type inertia piezoelectric motor

A piezoelectric single crystal and piezoelectric motor technology, which can be used in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. The development of science and technology, the price of multiple piezoelectric sheets, etc., to achieve the effect of saving materials, reducing costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

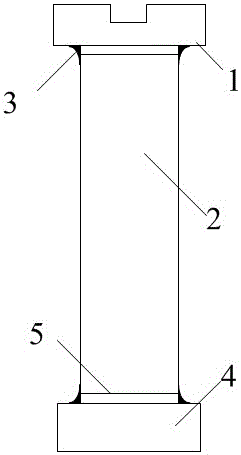

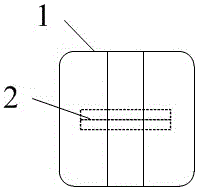

[0033] An inertial piezoelectric motor made of a piezoelectric single chip that is completely bonded to the widest surface of the piezoelectric sheet and the non-piezoelectric material support. In this embodiment, there are 1mm uncoated electrode parts 5 at both ends of the widest surface of the piezoelectric ceramic sheet. Base and rails are stainless steel.

[0034] The manufacturing process of the piezoelectric single-chip inertial piezoelectric motor of this embodiment is as follows:

[0035] (1) Select a piezoelectric single chip that is completely bonded to the widest surface of the piezoelectric sheet and the non-piezoelectric material support, so that it stands vertically between the stainless steel base and the guide rail;

[0036] (2) Use epoxy resin AB glue 353ND, and apply it on the contact part between the piezoelectric single chip and the stainless steel base and the guide rail;

[0037] (3) drying it to obtain the piezoelectric single-chip inertial piezoelectri...

Embodiment 2

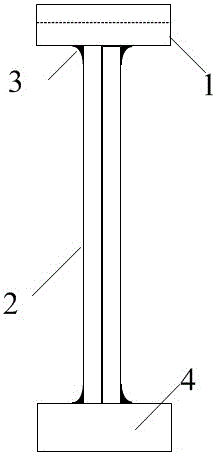

[0039] A piezoelectric monolithic inertial piezoelectric motor produced by fixing both ends of the piezoelectric sheet and the non-piezoelectric material support between the base and the guide rail. In this embodiment, the piezoelectric ceramic sheet is polarized along the thickness direction and has the widest surface There are 1 mm uncoated electrode parts 5 at both ends, and the non-piezoelectric material support body, base and guide rail are all stainless steel.

[0040] The manufacturing process of the piezoelectric single-chip inertial piezoelectric motor of this embodiment is as follows:

[0041] (1) Use piezoelectric ceramic sheets and stainless steel sheets with a size of 30*5*0.5mm;

[0042] (2) Place the piezoelectric ceramic sheet and the stainless steel sheet in parallel between the base and the guide rail, and set the piezoelectric ceramic sheet and the stainless steel sheet perpendicular to the base and the guide rail respectively. The distance between the piezo...

Embodiment 3

[0047] An inertial piezoelectric motor made of a piezoelectric single chip with both ends of the piezoelectric sheet and a non-piezoelectric material support body fixed with an insulating film. The electric single chip, its preparation method is the same as the manufacturing process of the piezoelectric single chip type inertial piezoelectric motor in embodiment 1.

[0048] The piezoelectric single-chip inertial piezoelectric motor of this embodiment uses a piezoelectric single-chip fixed with sapphire sheets at both ends of the piezoelectric sheet and the stainless steel sheet, which not only plays the role of insulation, but also plays a role of fixing. The overall structure Beautiful and practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com