Pipe threading attachment and adaptor for handheld drill

A technology of attachments and adapters, applied in thread cutting tools, manufacturing tools, metal processing equipment, etc., can solve the problems of cumbersome, expensive and lack of pipeline tapping methods, and achieve the purpose of reducing physical fatigue, simplifying handling and Portability, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

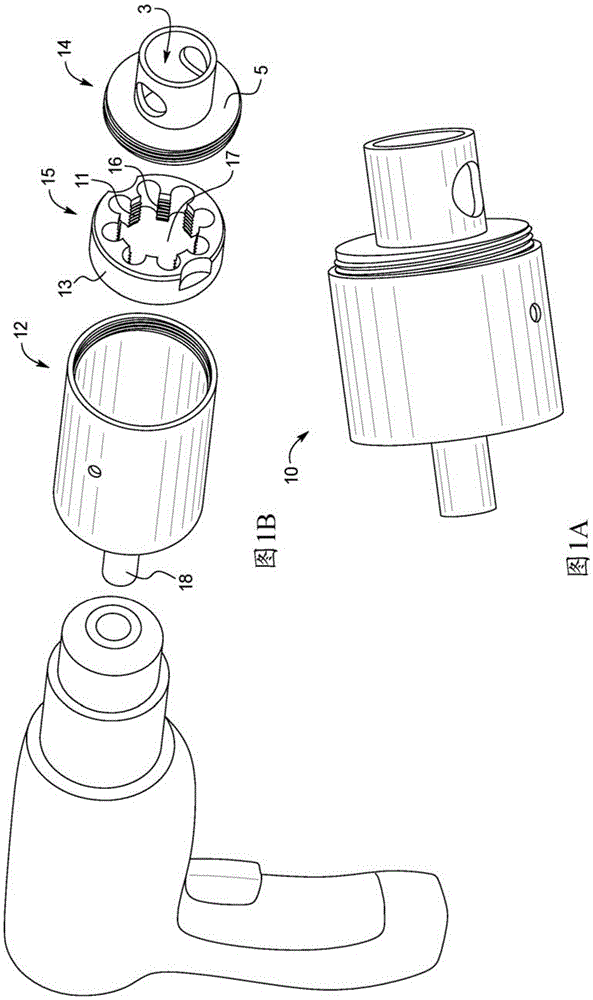

[0027] The present invention is directed to a pipe threading system 10 comprising an adapter 12 and an attachment 14 for a hand-held power drill, the system 10 being suitable for threading the outer diameter of a pipe. System 10 includes at least one die 16 shaped to cut threads on the outer surface of the pipe. The attachment 14 includes a central bore 20 to allow insertion of pipe, thereby enabling tapping of a portion of the pipe extending beyond the length of the cutting surface of the die.

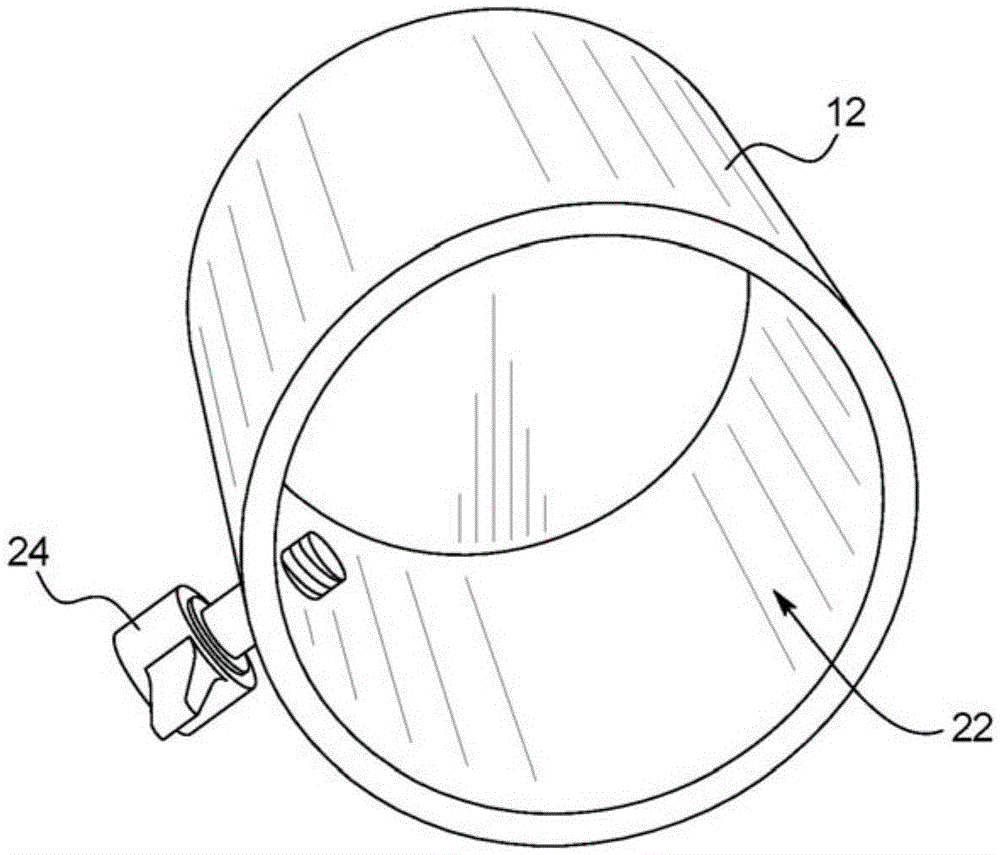

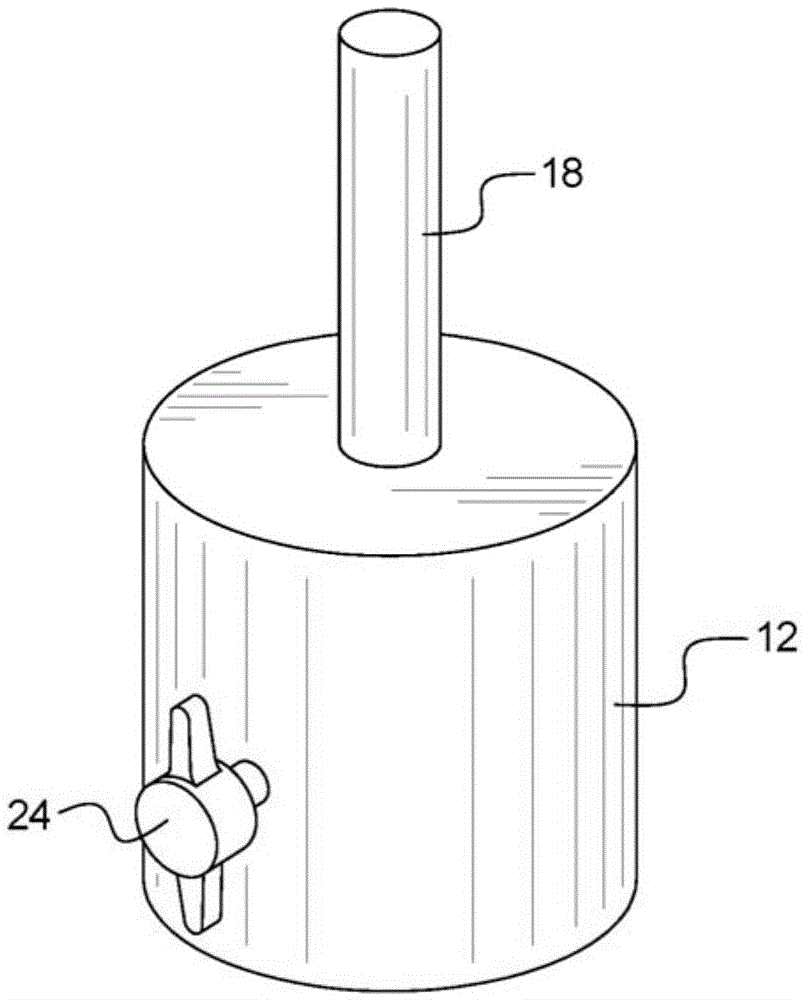

[0028] Such as Figure 1A , 1B As shown, an adapter 12 is used to attach an attachment 14 to a hand held power drill. The adapter part 12 can consist of ferrous alloys, other metal alloys or polymers. The adapter 12 may include a cylindrical cavity 22 for receiving the cylindrical insert 15 and / or the attachment 14 . The adapter 12 may also include a spindle 18 that fits into the chuck of the hand-held power drill. The spindle 18 extends from the closed end of the cylindrical cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com