Water incoming end cap for dielectrophoresis disc-tube membrane component and disc-tube membrane component

A technology of disc-tube membrane and dielectrophoresis, which is applied in the direction of membrane, membrane technology, and semi-permeable membrane separation, can solve the problems of inconvenient equipment compact installation, achieve insulation and water inlet and outlet functions, reduce space interference, The effect of strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

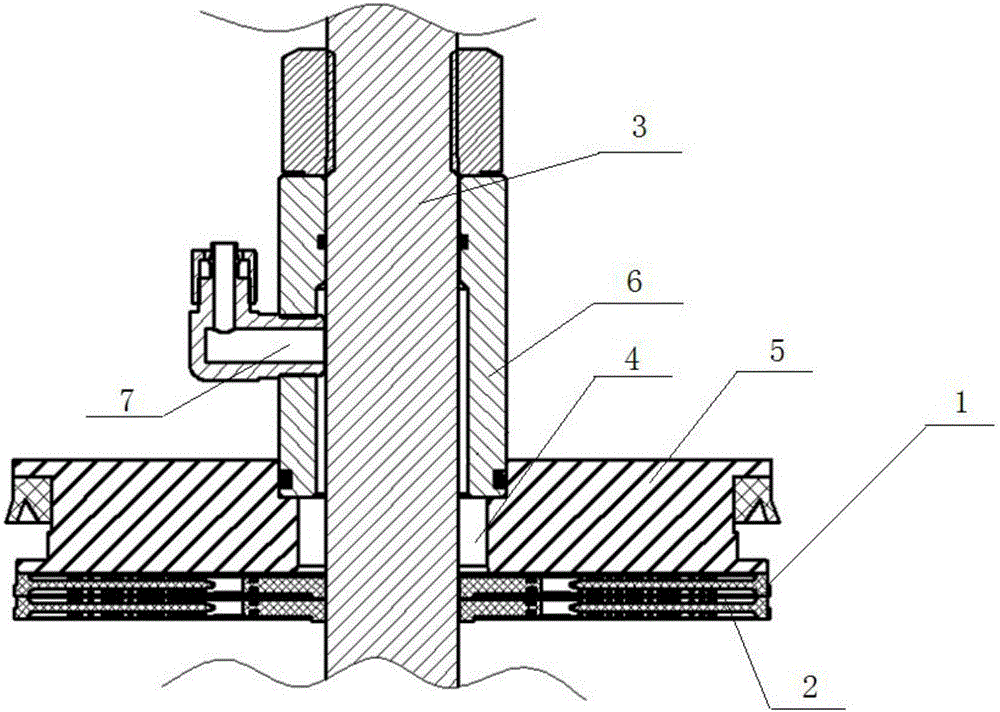

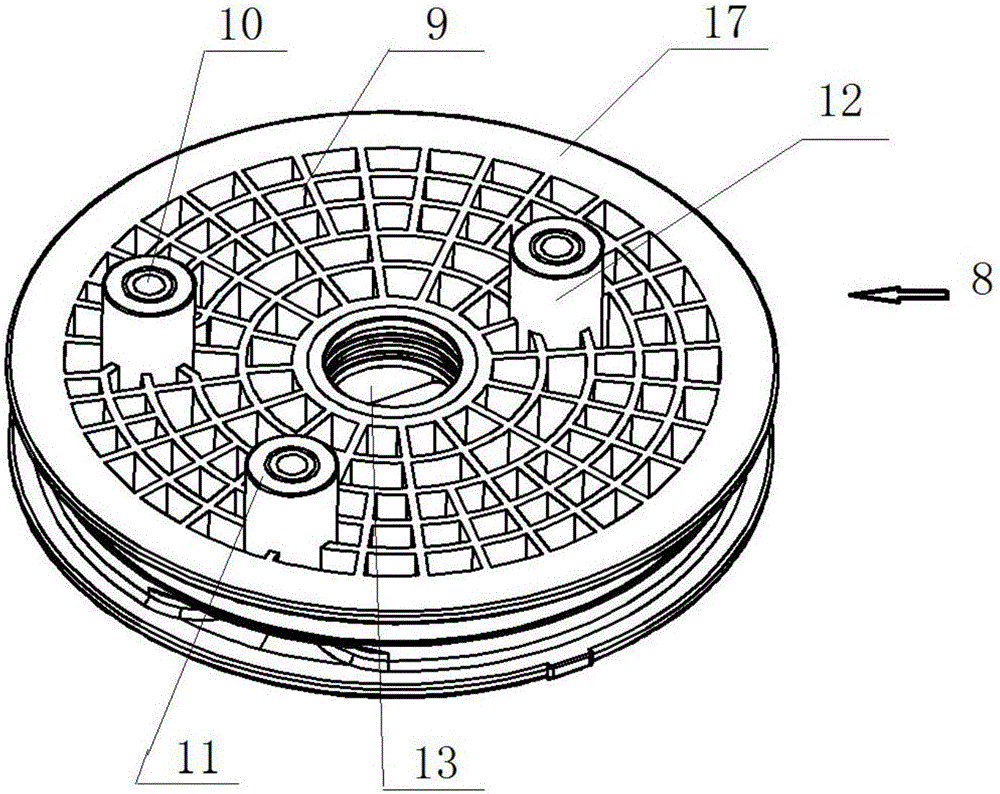

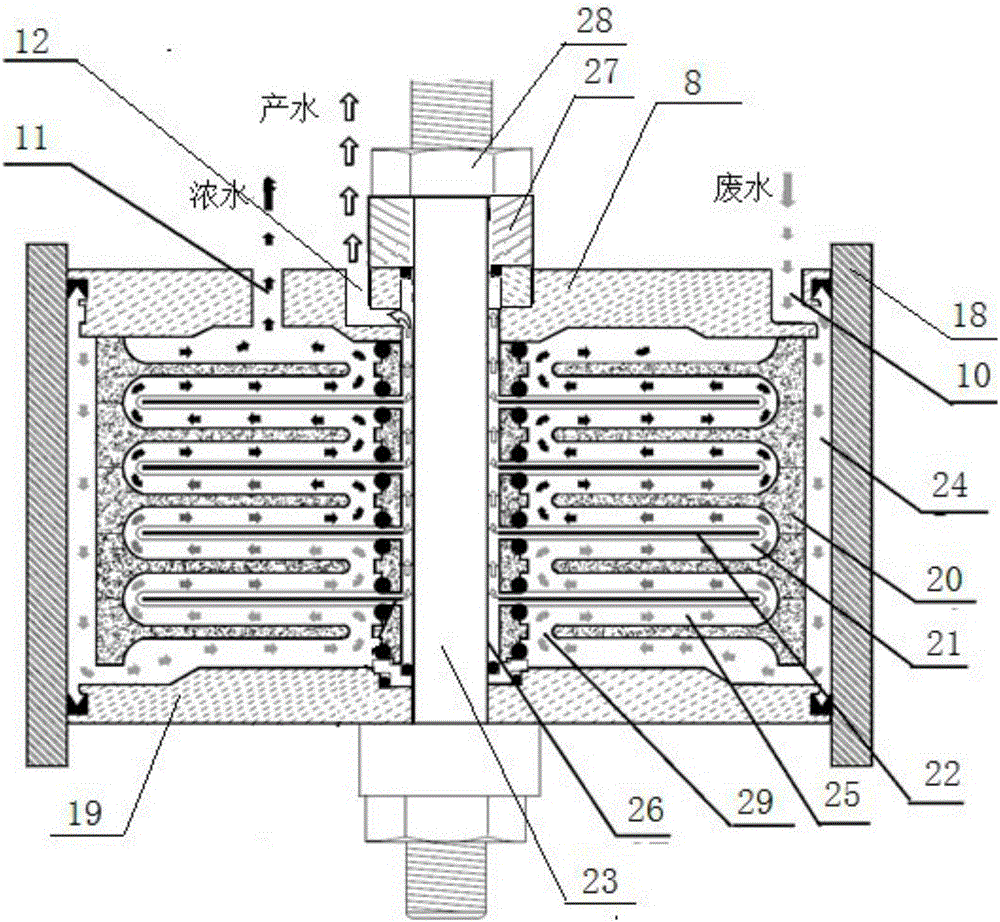

[0035] A kind of water inlet end cover used for dielectrophoresis dish tube type membrane module, such as Figure 5 , Image 6 As shown, the water inlet end cover 8 includes a cover body 17 of insulating material, and the cover body 17 is integrally formed by injection molding. A waste water channel 14, a concentrated water channel 15, and a water production channel 16 are formed inside the cover body 17 of the water inlet end cover. And the central through hole 13. like figure 2 As shown, the outer surface of the cover body 17 is formed with a waste water inlet 10, a concentrated water outlet 11 and a water production outlet 12 respectively corresponding to the waste water channel 14, the concentrated water channel 15, and the produced w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com