Anchor type stirring device

An anchor-type stirring and anchor-type technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problem of poor mixing in the middle position of the blades, and prevent the blades from being deformed and damaged. strength, drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

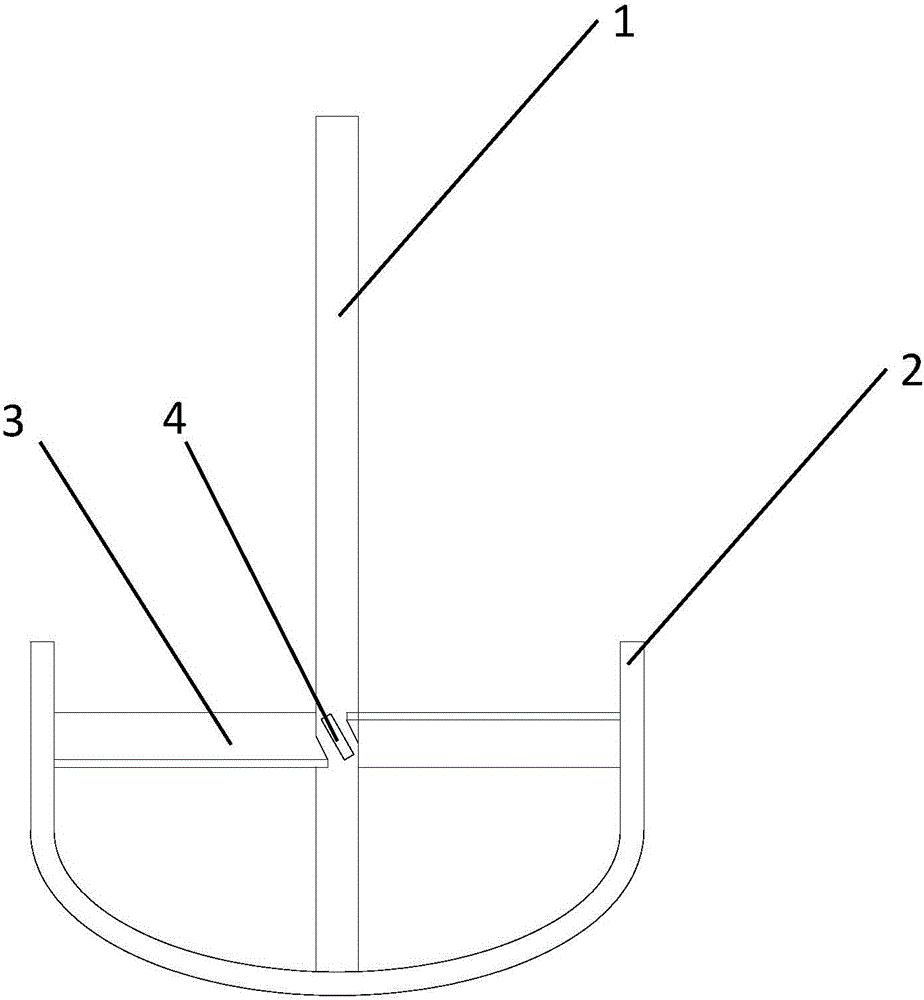

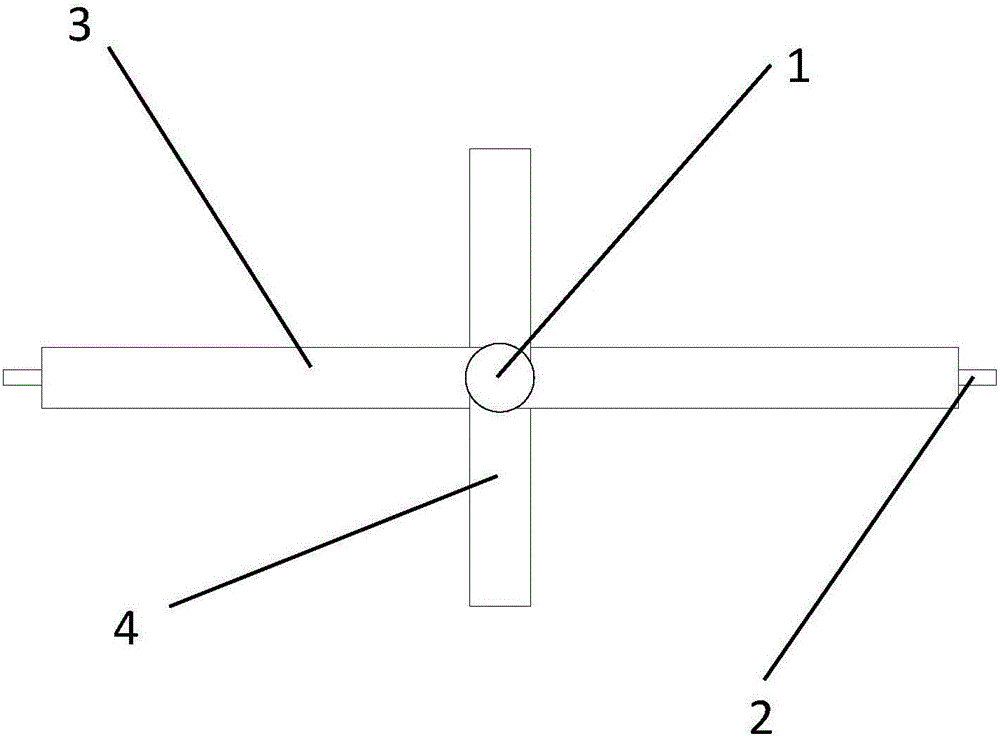

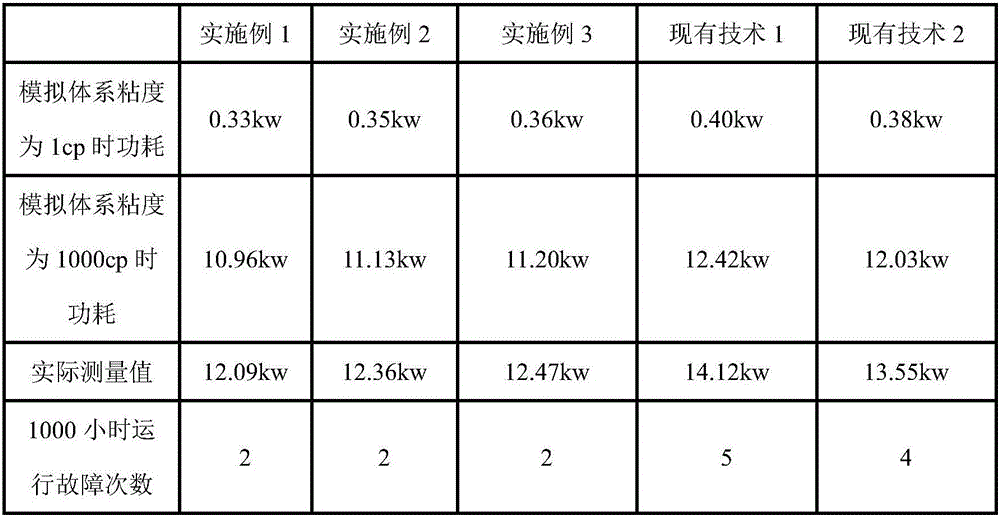

[0010] Reference attached figure 1 and 2 A kind of anchor stirring device shown, comprises stirring shaft 1, and anchor stirring paddle 2 is arranged at the lower end of stirring shaft, is provided with two connecting arms 3 between stirring shaft and anchor paddle blade, and described connecting arm is Push-down inclined-blade blades; perpendicular to the plane of the anchor-type blades, two short push-down inclined-blade blades 4 are arranged at the position of the connecting arm on the stirring shaft. The inclination angle of the connecting arm push-down inclined blade and the short push-down inclined blade is 40°, and the diameter of the short push-down inclined blade is 0.4 times the diameter of the anchor blade.

Embodiment 2

[0012] Reference attached figure 1 and 2 A kind of anchor stirring device shown, comprises stirring shaft 1, and anchor stirring paddle 2 is arranged at the lower end of stirring shaft, is provided with two connecting arms 3 between stirring shaft and anchor paddle blade, and described connecting arm is Push-down inclined-blade blades; perpendicular to the plane of the anchor-type blades, two short push-down inclined-blade blades 4 are arranged at the position of the connecting arm on the stirring shaft. The inclination angle of the connecting arm push-down inclined blade and the short push-down inclined blade is 45°, and the diameter of the short push-down inclined blade is 0.5 times the diameter of the anchor blade.

Embodiment 3

[0014] Reference attached figure 1 and 2 A kind of anchor stirring device shown, comprises stirring shaft 1, and anchor stirring paddle 2 is arranged at the lower end of stirring shaft, is provided with two connecting arms 3 between stirring shaft and anchor paddle blade, and described connecting arm is Push-down inclined-blade blades; perpendicular to the plane of the anchor-type blades, two short push-down inclined-blade blades 4 are arranged at the position of the connecting arm on the stirring shaft. The inclination angle of the connecting arm push-down inclined blade and the short push-down inclined blade is 50°, and the diameter of the short push-down inclined blade is 0.5 times the diameter of the anchor blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com