Magnetic-control high-voltage electrostatic atomizing device

A high-voltage electrostatic and atomization device technology, applied in the direction of spray discharge device, etc., can solve the problems of affecting the spray effect and the time of the substance to be atomized affecting the substance to be atomized, so as to increase the action path and enhance the ionization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

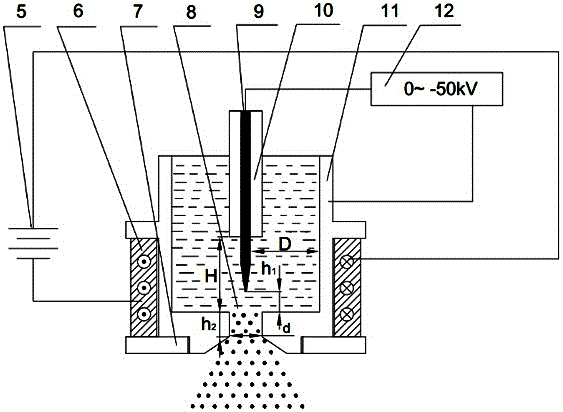

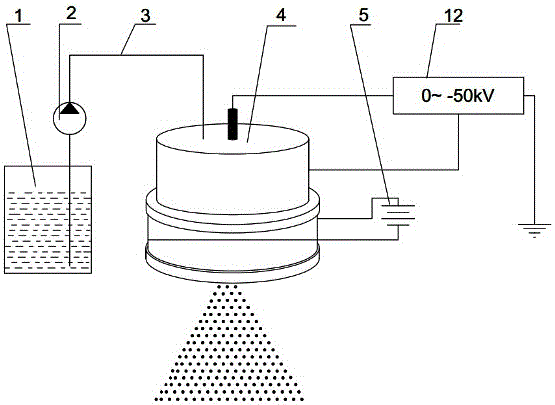

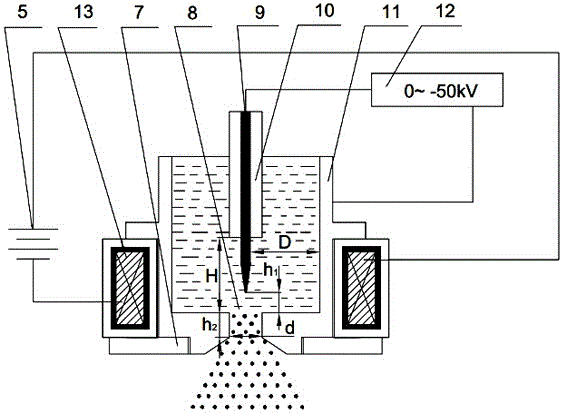

[0018] like figure 1 and figure 2 As shown, the first embodiment of the present invention is a magnetically controlled high-voltage electrostatic atomization device based on an ordinary electromagnetic coil to establish an atomizing magnetic field, which includes a liquid storage tank 1, a metering pump 2, an infusion conduit 3 and a nozzle 4, and the The suction end of the metering pump 2 is connected to the liquid storage tank 1 through the infusion conduit 3 , and the output end of the metering pump 2 is connected to the nozzle 4 through another infusion conduit 3 . The nozzle 4 includes a DC voltage source 5, an electromagnetic coil 6, a retaining ring 7, a spray point 8, a spray electrode 9, an insulating sleeve 10, a reference elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com