Wind power foundation anchor bolt anticorrosion construction method

A construction method, wind power-based technology, applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems of high cost and difficult to handle parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

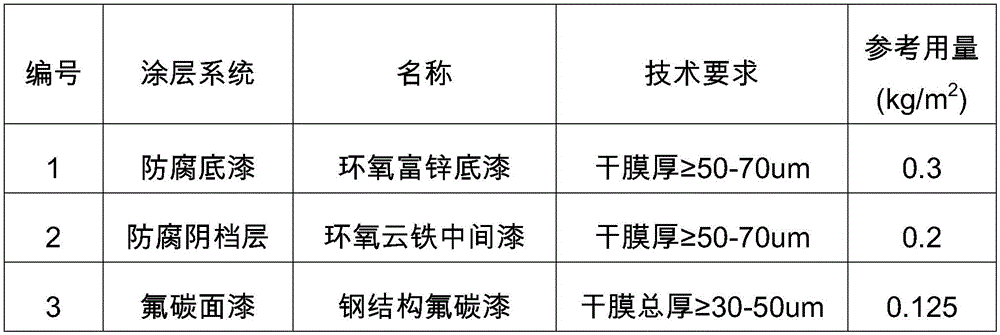

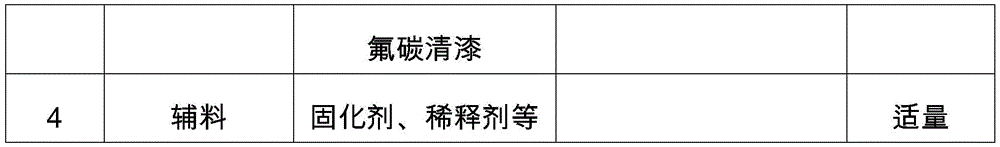

[0031] see figure 1 , is an anti-corrosion construction method for wind power foundation anchor bolts provided by an embodiment of the present invention. The wind power foundation anchor bolt anticorrosion construction method described in the present invention provides a non-metallic coating, which can effectively prevent and delay the surface corrosion of the anchor bolt, and improve the durability and service life of the wind power foundation anchor bolt. The method provided is a simple Reasonable, cost-effective anti-corrosion method. The anchor bolts constructed by this method have the characteristics of super weather resistance and super corrosion resistance. Using a variety of coatings, multi-functional anti-corrosion, can resist the corrosion of various harsh media, the salt spray resistance of the system is 5000-10000 hours, and the outdoor service life is more than 20 years.

[0032] like figure 1 As shown, the anchor bolt includes a middle section and threaded sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com