Spinning wheel used for machining wind tunnel flange

A technology of spinning wheels and flanges, which is applied in the field of metal plastic forming machinery, can solve the problems that the plane perpendicular to the center line of the air cylinder cannot be achieved, the surface flatness of the bell mouth-shaped air cylinder is unqualified, and the processing accuracy of the workpiece is low, etc., to achieve Light weight, eliminate rough smooth, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Combined with the accompanying drawings below ] The present invention further illustrates:

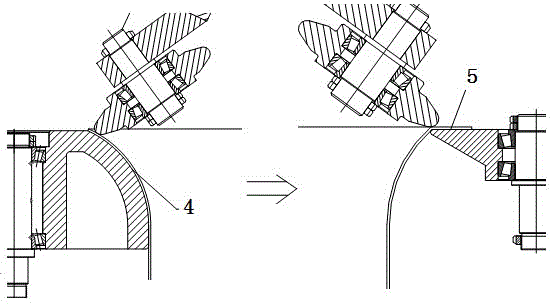

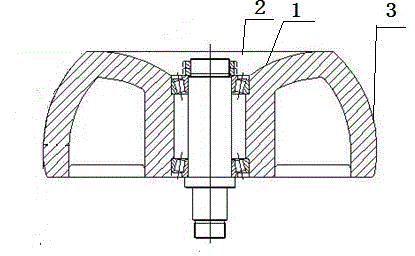

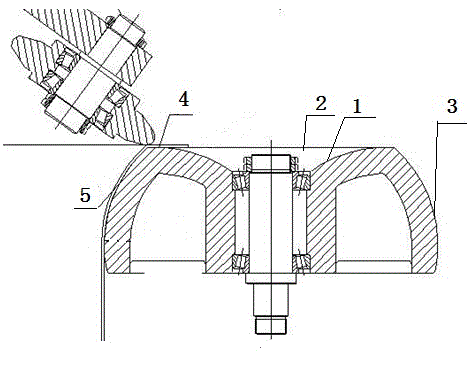

[0015] As shown in the attached figure, a spinning wheel for processing the flange of the blower is provided with a bottom spinning wheel, and the center of the bottom spinning wheel is provided with a mounting hole, which is characterized in that the upper end surface of the bottom spinning wheel It is an arc-shaped surface 1. The arc-shaped surface 1 gradually deviates from the horizontal plane from the outer end to the center and extends downward to the installation hole in an arc shape, so that the upper end surface is concave 2, which is beneficial to ensure that the spinning method During the spinning process, the flange surface is plastically rebounded to the horizontal position, so that the flange surface of the bell mouth-shaped fan cylinder and the horn forming surface are integrally formed, which greatly facilitates the processing, and also improves the work efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com