An assembly/maintenance dock for aircraft of the same series

A technology of one series and one aircraft, applied in aircraft maintenance, aircraft assembly, etc., can solve the problems of large footprint, stable aircraft and maintenance personnel safety hazards, complex dock structure, etc., to achieve reduced rotational friction, Superior trafficability for people and vehicles, flexible operation and more labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

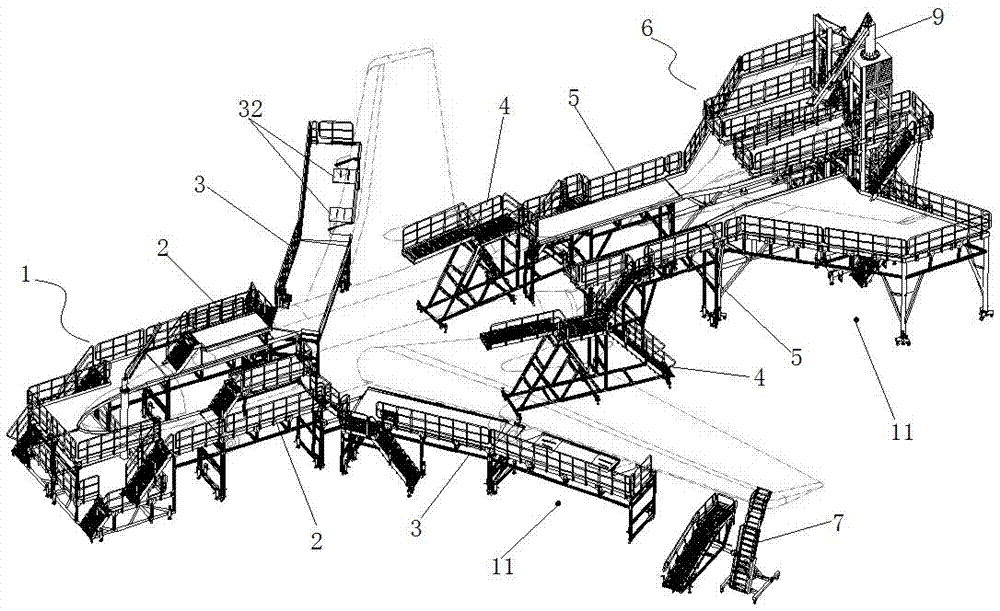

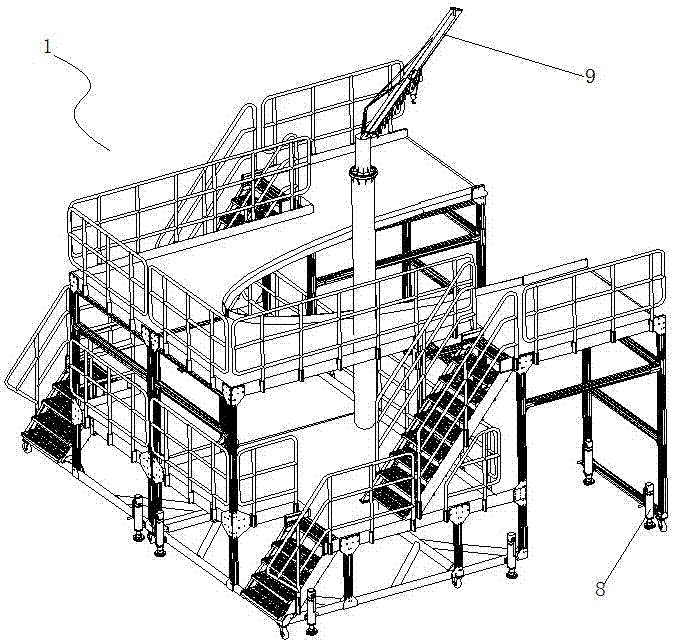

[0073] like Figure 1-14 As shown, an assembly / maintenance dock of the same series of aircraft includes a nose dock 1, a fuselage dock 2, a wing dock 3, an engine platform 4, a tail dock 5, and an empennage dock 6, which are detachably connected in sequence. The lower parts of the nose dock 1, the fuselage dock 2, the wing dock 3, the tail dock 5, and the empennage dock 6 are all provided with a driveway 11.

[0074] The nose dock 1 and the empennage dock 6 are respectively provided with a rotary crane 9, and the rotary crane 9 includes a rotary bearing 91, a horizontal L-shaped load-bearing bracket 92 fixed on the rotary bearing 91, and a load-bearing bracket 92 installed on the bearing bracket 92. The electric crane 93, and the transmission assembly and the control box 94 that control the rotation of the slewing bearing 91.

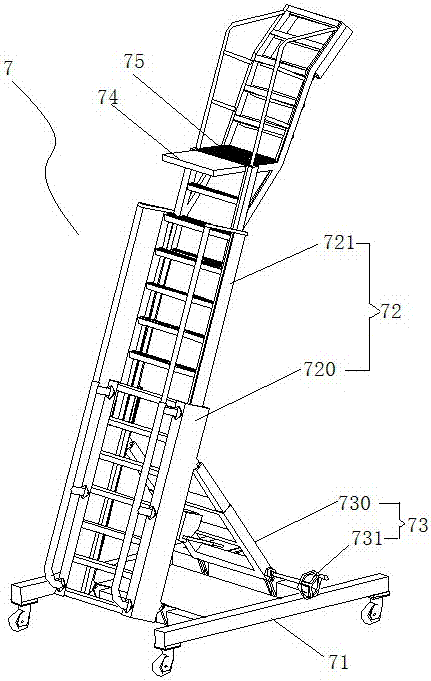

[0075] Also comprise the common platform 7 that is used for aircraft cabin and lower maintenance assembly, described universal platform 7 comprises ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com