Automatic board feeding machine for printed circuit board (PCB) and automatic board feeding method of automatic board feeding machine

An automatic board loading machine and PCB board technology, applied in the field of automation, can solve the problems affecting the automation process of the PCB board, can not achieve full automation, PCB board pollution, etc., to achieve the effect of saving manpower, high degree of automation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

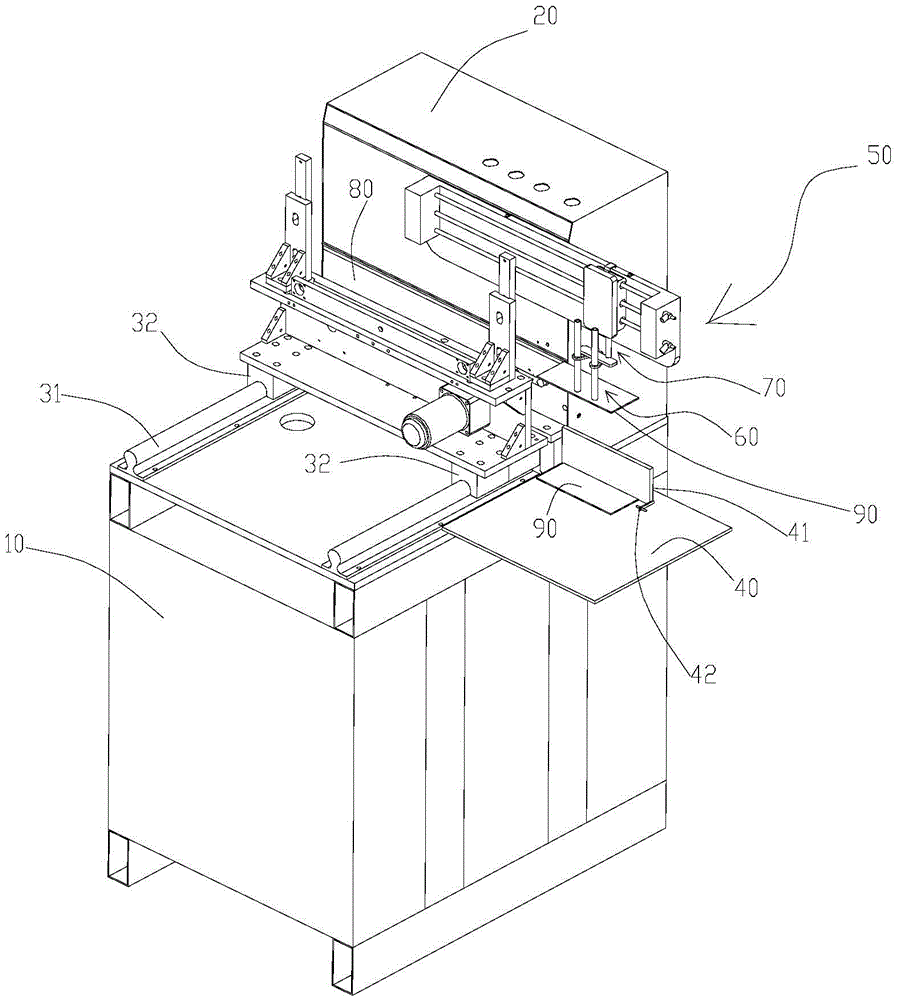

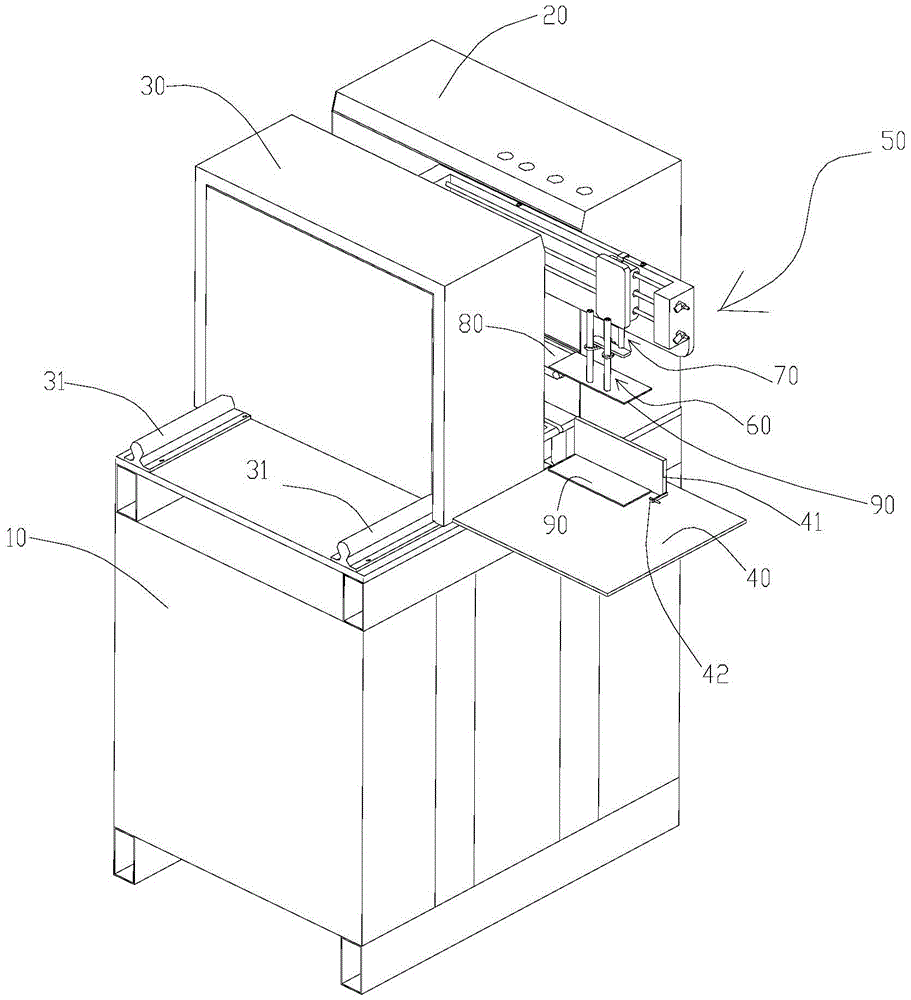

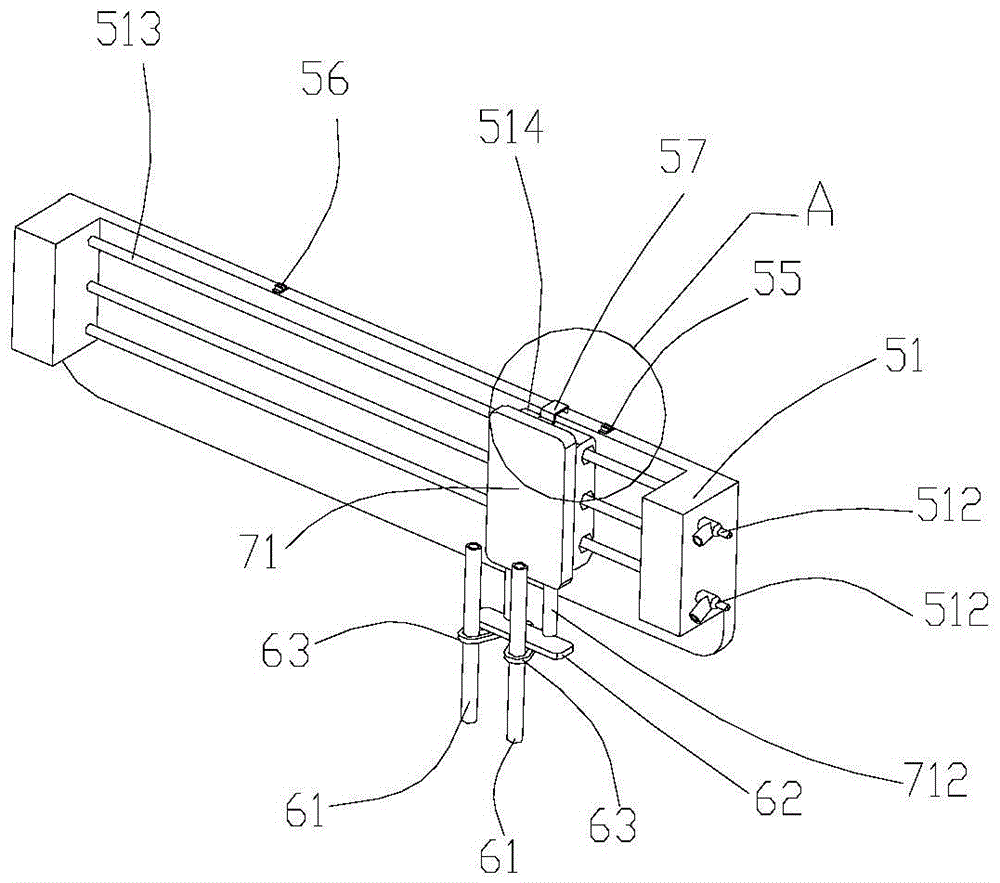

[0029] like figure 1 and figure 2 As shown, an automatic PCB board loading machine is placed on the base 10, the base 10 is provided with a chassis, the chassis is divided into a front box 20 and a rear box 30 arranged in parallel, and the space between the rear box 30 and the front box 20 is Adjustable; between the front box 20 and the rear box 30, there is a conveying device 80 that can transfer the PCB board to the subsequent process, and a feeding rack 40 is provided near the starting end of the conveying device 80, which also includes the PCB board from the feeding. The rack 40 is transported to the transfer device on the transfer device 80. The front box 20, the rear box 30, the loading rack 40, the transfer device, and the transfer device 80 are programmed through the PLC control system to realize the coordination of the work process between each other. The wires for electrical communication connection, the power system of each component, etc. are hidden in the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com