Cloth clamping device with tensioning effect

A cloth coder and cloth carding technology, which is applied in the directions of transportation and packaging, winding strips, and folding thin materials, etc., can solve the problems of easy wrinkle carding effect of cloth, unsatisfactory carding effect, and cloth wrinkles, etc., to achieve Improve the effect of jamming, anti-deviation of the jamming effect, and prevent wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

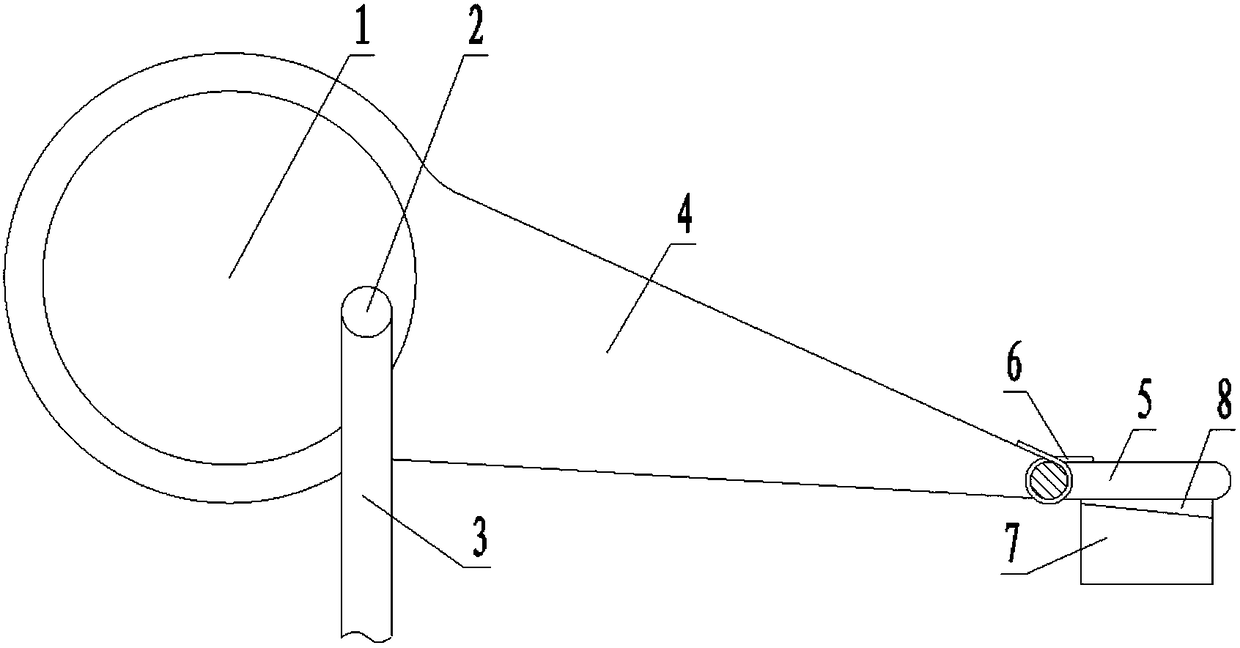

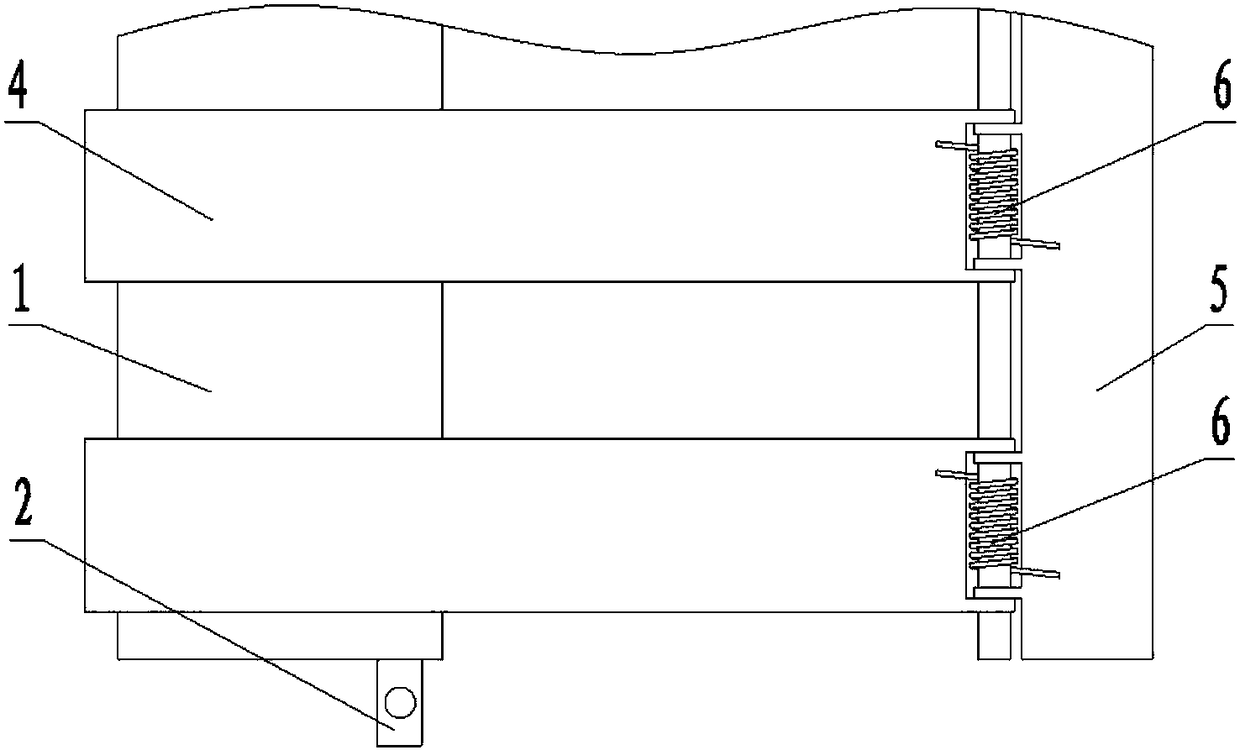

[0013] Example. The cloth coder clamping device with tensioning effect is composed of figure 1 , 2 As shown in . A tension piece 5 is hinged at the end of the head 4 , and a torsion spring 6 is connected between the tension piece 5 and the collet 4 .

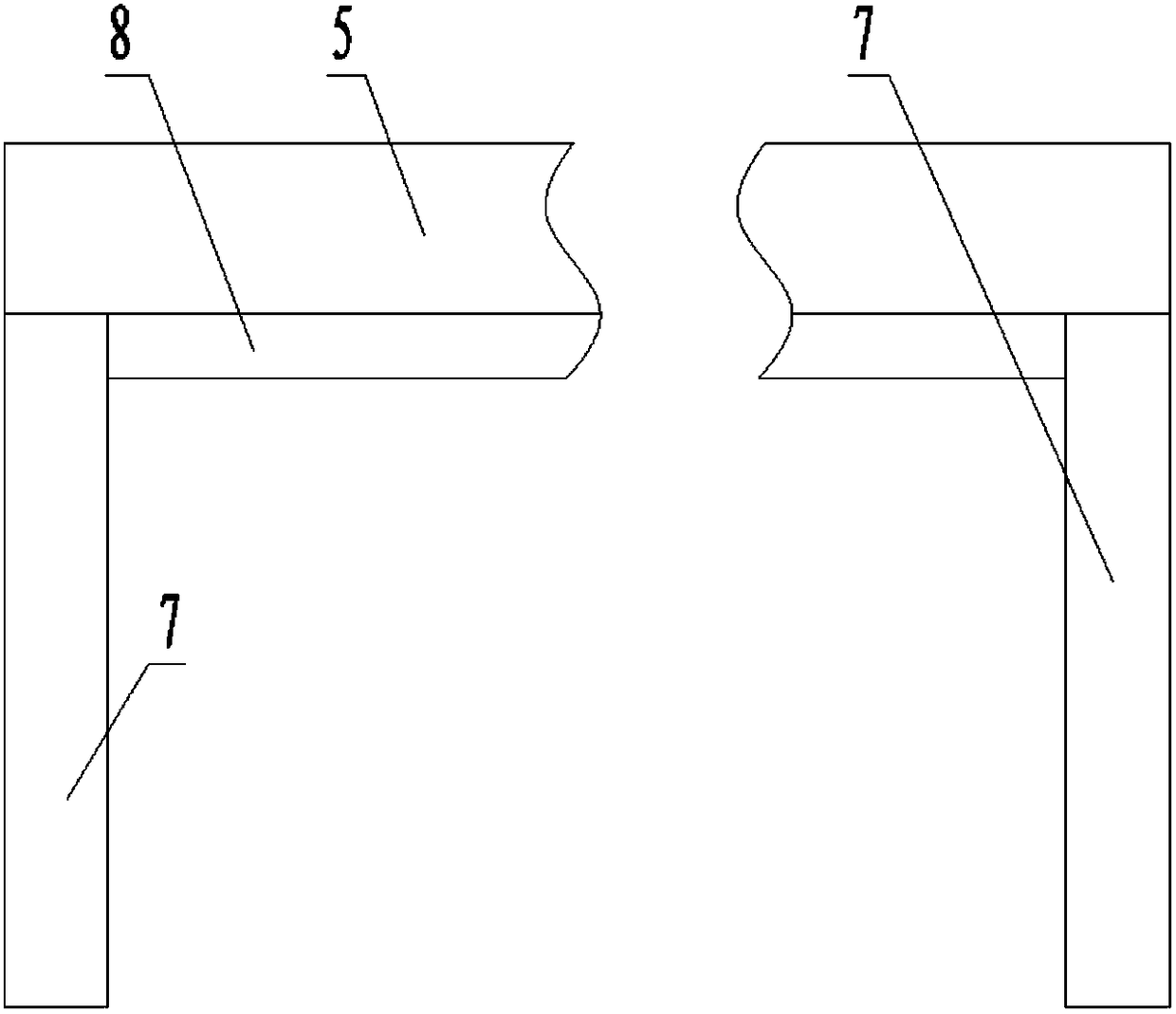

[0014] The bottoms of both sides of the tensioning sheet 5 are connected with limiting sheets 7 . A wedge-shaped rubber sheet 8 is also arranged on the lower surface of the tension sheet 5 .

[0015] Working principle: as figure 1 , 2 , 3, when the cloth is pushed by the code knife, the driving rod 3 pushes the connecting rod 2 upward to make the rotating shaft 1 rotate. Pull the connecting rod 2 downward to rotate the rotating shaft 1 in the opposite direction, and the rotating shaft 1 drives the chuck 4 and the tensioning sheet 5 to turn down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com