Liquid phase stripping preparation method for phosphaalkene nanoribbon or phosphorus nanoribbon

A nano-ribbon, liquid phase exfoliation technology, applied in the preparation of phosphorus, etc., can solve the problems of low efficiency, unsatisfactory thickness of phosphorene, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps: prepare strips, rectangular flake-shaped black phosphorus and DMSO solutions according to the concentration of 0.02g / mL to prepare a solution, and perform an ultrasonic reaction at a stripping reaction temperature of 30°C with a power of 50W for 6 hours; Centrifuge at 14,000 rpm for 30 minutes in a centrifuge, and take the supernatant; drop the solution on a silicon wafer and dry it at 90° C. to obtain phosphorene nanobelts.

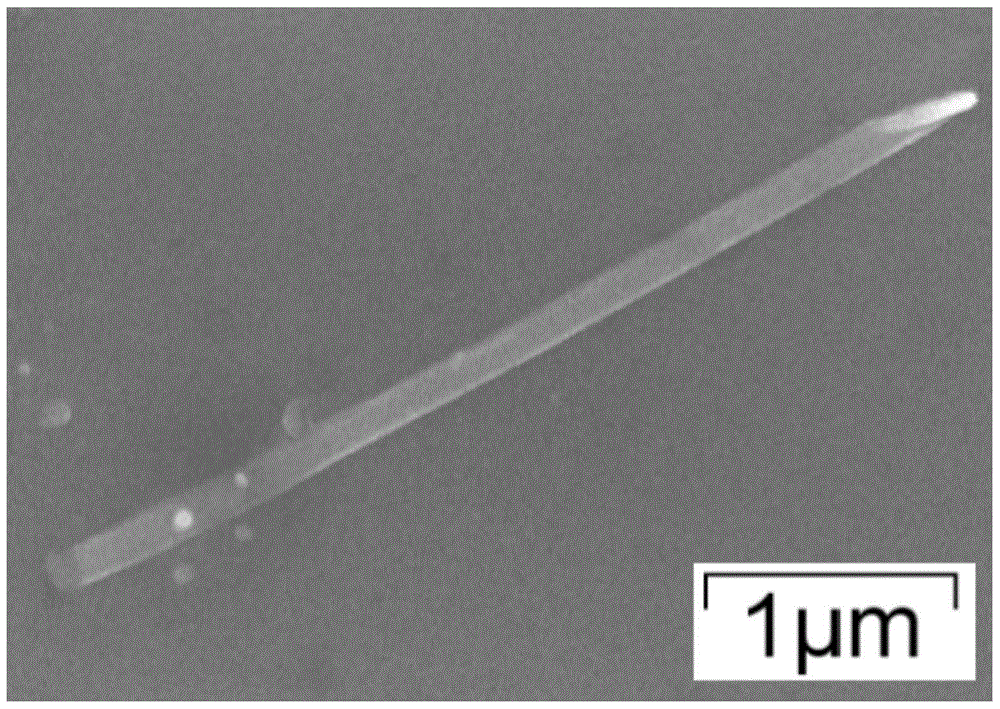

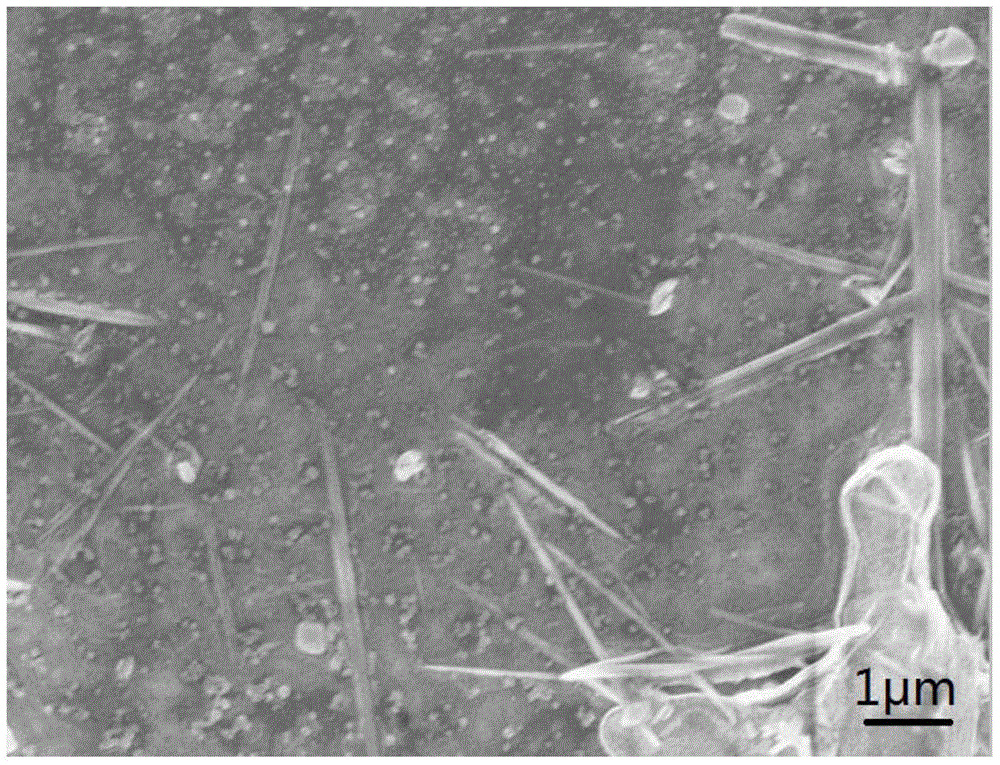

[0024] Such as figure 1 Shown are the SEM photos of the prepared phosphorene nanoribbons and phosphorous nanoribbons.

Embodiment 2

[0026] This embodiment includes the following steps: prepare the mixed solution of strips, rectangular sheets of black phosphorus, DMSO, NMP and DMF according to the concentration of 0.2g / mL, and ultrasonically react for 24 hours at a stripping reaction temperature of 30°C; After ultrasonication, the solution was centrifuged in a centrifuge at 14,000 rpm for 30 minutes, and the supernatant was taken; the solution was dropped on a silicon wafer, spin-coated at 500 rpm for 60 seconds, and dried at 90°C to obtain phosphorene nanobelts.

Embodiment 3

[0028] The present embodiment comprises the following steps: the solution prepared by mixing strips, rectangular flake-shaped black phosphorus and DMSO, NMP and DMF mixed separating agent with alcohols and a concentration of 0.5g / mL is prepared, and the solution is prepared at the stripping reaction temperature Ultrasonic reaction at 30° C. for 48 hours; centrifuge the ultrasonic solution at 14,000 rpm for 30 minutes in a centrifuge to take the supernatant; drop the solution on a silicon wafer and dry it at 90° C. to obtain phosphorene nanobelts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com