An improved equipment for p5000 machine bpsg process

A machine and equipment technology, applied in the field of equipment improvement of BPSG process, can solve the problems of small design space of HOTBOX, out-of-service support for TEOS doping-related configuration parts, and difficulty in replacement and maintenance of pipe and valve parts, so as to achieve cost saving and high efficiency. Effect of liquid source supply device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

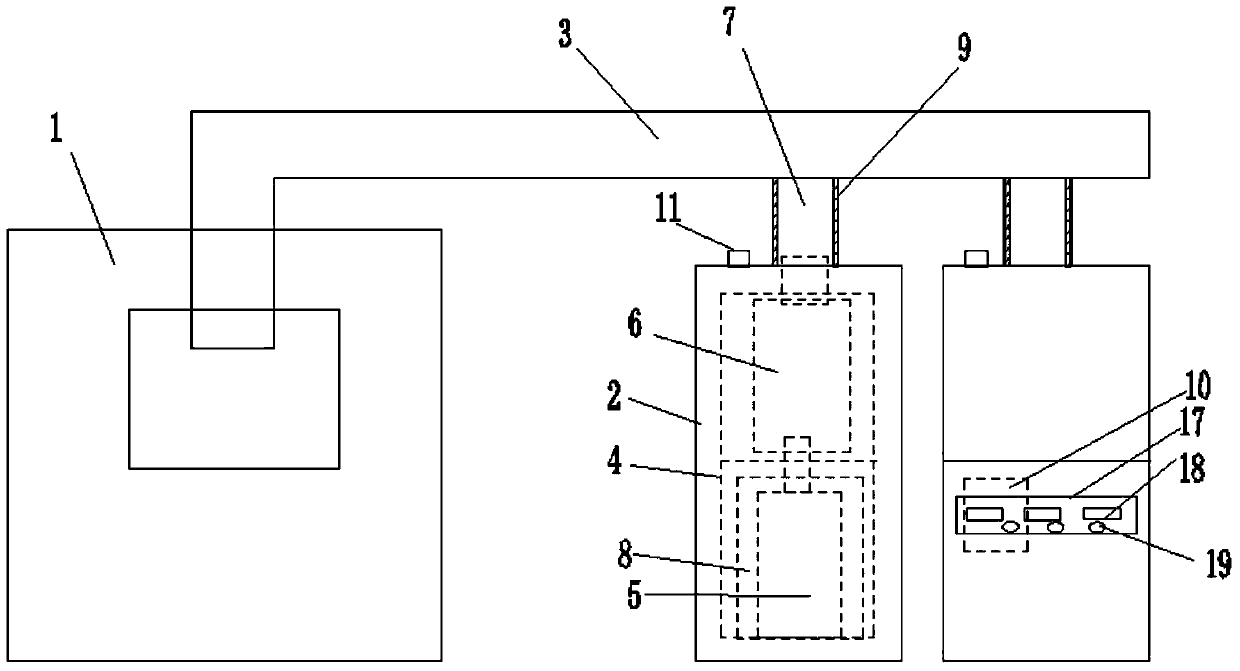

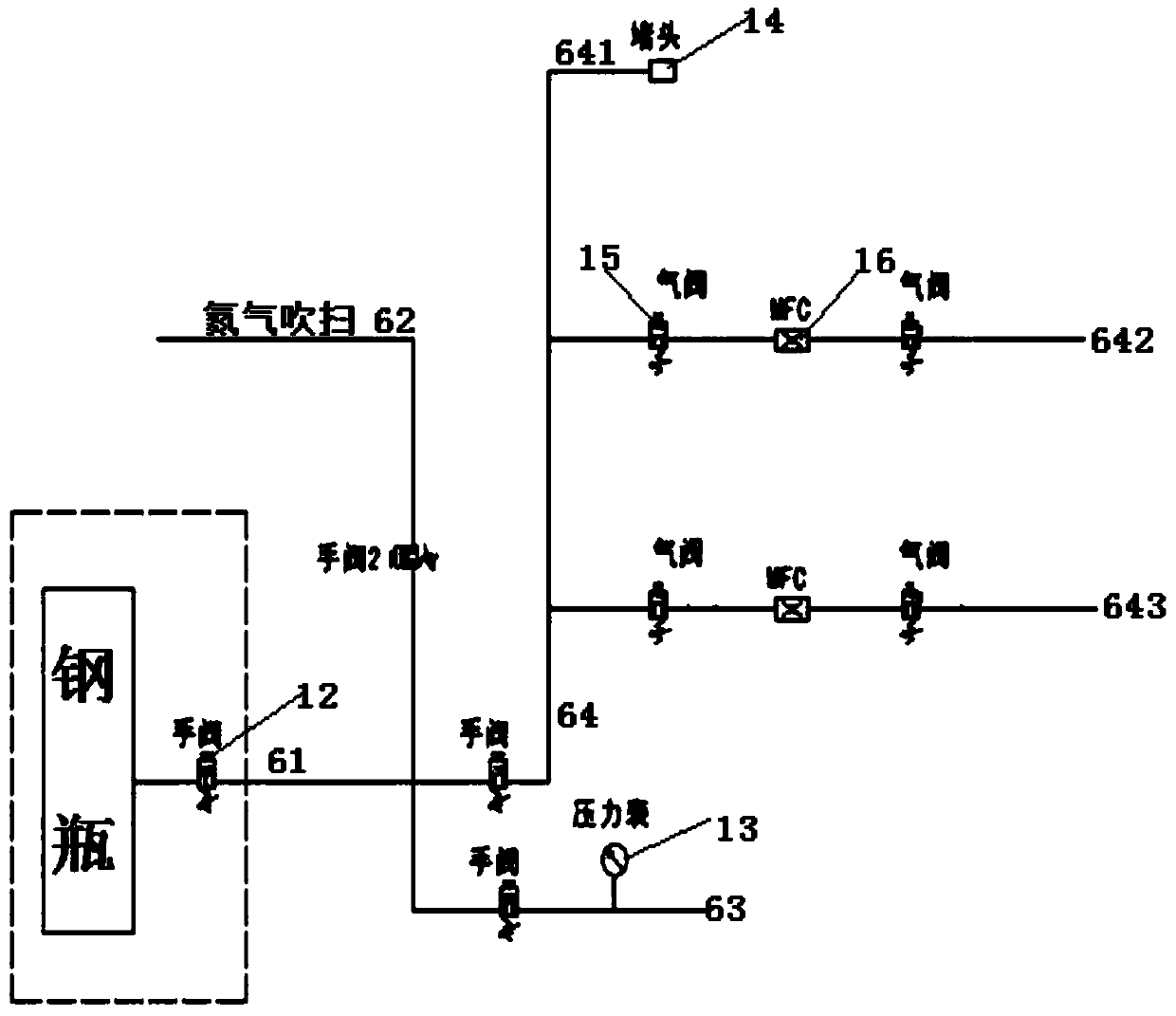

[0027] Embodiment: A kind of improved equipment of P5000 machine BPSG technology, comprises P5000 machine body 1 and two independent cabinets 2, the top of described P5000 machine body is installed with TEOS pipeline 3, the inside of described cabinet A small set of cabinets 4 is installed, and the small set of cabinets is a two-layer structure. The lower layer of the small set of cabinets is placed to store a steel cylinder 5 with a liquid source, and the upper layer is equipped with a liquid source output pipeline system 6. The liquid source output The pipeline system communicates with the steel cylinder, and also includes a liquid source lead-out pipeline 7, the liquid source lead-out pipeline is installed above the cabinet, one end of the liquid source lead-out pipeline is connected to the liquid source output The pipeline system is connected, and the other end is docked with the TEOS pipeline. A heater 8 is installed on the lower layer of the small cabinet, the steel cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com