Anti-scaling agent for oil well silicate scale

A technology of silicate and anti-scaling agent, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problem of low silicate scale anti-scaling rate, affecting the normal production of oil fields, the economic benefits of ASP flooding, and the stuck pump etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1. Determination of corrosion rate of anti-scaling agent: Measure the size of a standard N80 steel sheet with a vernier caliper and calculate the surface area. Wipe it with absorbent cotton, wash it with absolute ethanol, soak and dehydrate it for 5 minutes, take out the test piece and immediately dry it with filter paper, blow it dry with a cold fan, put it in a desiccator for 30 minutes, and weigh it to the nearest 0.0001g. Fix and immerse the test piece in a 500mL jar filled with 500mg / L antiscalant solution, and place the jar in a constant temperature water bath at 45°C for 7 days. Take out the test piece, rinse it with clean water first, then gently brush it with a brush, then blot it dry with filter paper and soak it in absolute ethanol for 5 minutes, take out the test piece and immediately dry it with filter paper, blow it dry with a cold fan, and put it in a dry place. After 15 minutes in the container, it is weighed to an accuracy of 0.0001g, and the co...

Embodiment 2

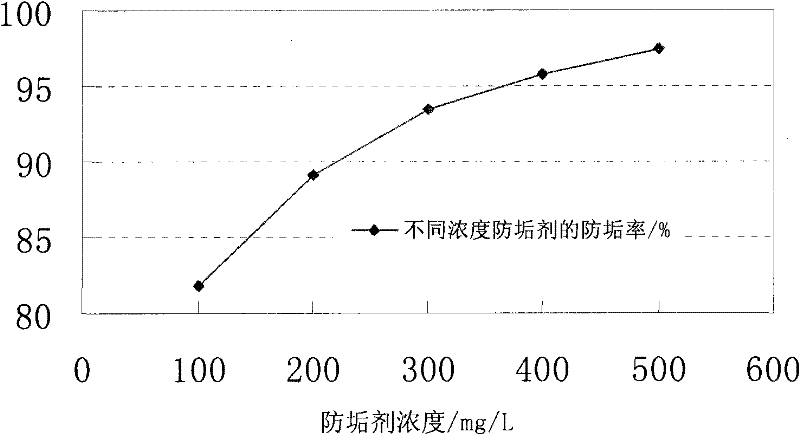

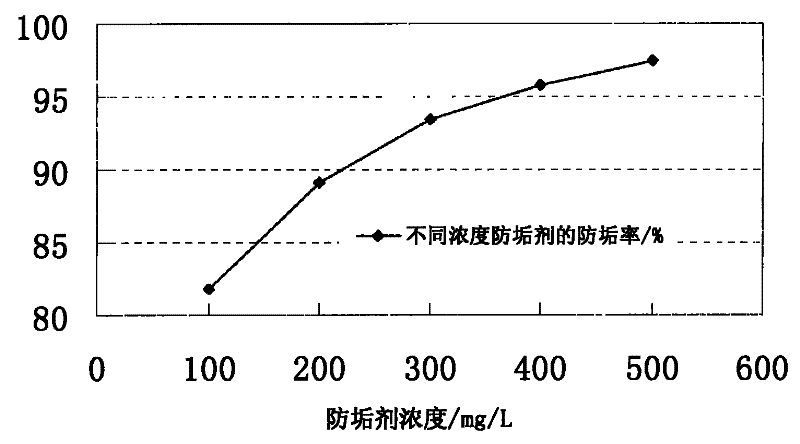

[0032] Embodiment 2, the antiscaling rate measurement of antiscaling agent: add each antiscaling agent in the wide mouth bottle that Daqing salt water is housed respectively, then add magnesium chloride solution, calcium chloride solution in each bottle, shake well and then Add sodium silicate solution, so that the concentrations of various substances in the solution are: anti-scaling agent 100mg / L, Ca 2+ 200mg / L, Mg 2+ 65mg / L, Si 4+ 500mg / L. Close the cork tightly, mix the solution, place the solution in the bottle in a constant temperature water bath at 45°C for 24 hours, take it out and test the concentration of silicon ions in the solution with an atomic absorption spectrophotometer, the anti-scaling rate E is calculated according to the following formula, the experimental results See Table 2.

[0033]

[0034] In the formula: E-anti-fouling rate;

[0035] C 2 - the concentration of silicon ions in the mixed solution after adding the antiscalant;

[0036] C 1 -Co...

Embodiment 3

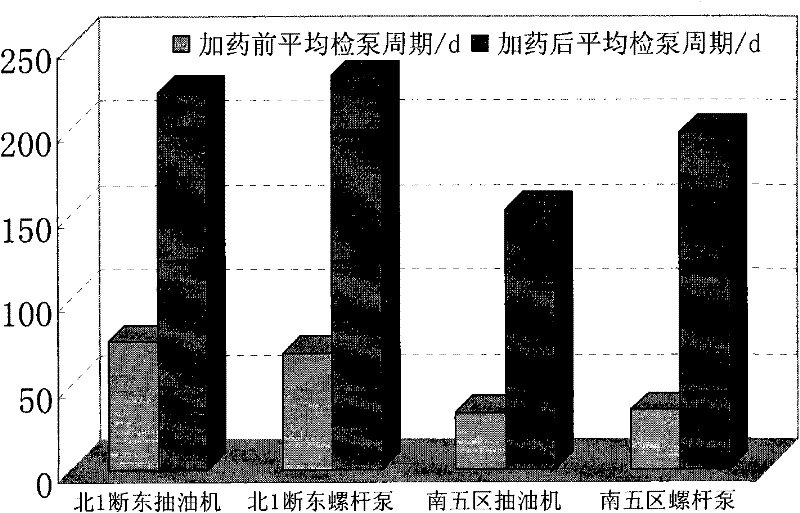

[0044] Example 3. On-site anti-scaling effect test of the anti-scaling agent SY-KD of the present invention in ternary oil wells: Well South 5-10-P32 in the South 5 Block of Daqing Oilfield, in January, February and March 2008, the pump was stuck three times in a row due to scaling During the operation, the rods and pipes were seriously fouled, and the thickness of the scale layer was about 1mm. The average pump inspection cycle was only 21 days, and the well had already entered the fouling period. Take the scale samples of rods and tubes and other parts for indoor analysis, the average content of silicate scale is 63.6%, and the average content of carbonate scale is 31.8%.

[0045] On March 24, 2008, anti-scaling agent SY-KD was used in South 5-10-P32 well for anti-scaling dosing. Scale agent SY-KD is continuously added into the wellbore from the oil casing annulus to form a stable concentration in the production fluid medium to prevent silicate scaling. Anti-scaling agent S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| anti-fouling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com