Method for efficiently and quickly extracting paclitaxel, cephalomannine and 10-DAB III from Taxus chinensis

A technology of cephalomannine and paclitaxel, which is applied in the direction of organic chemistry, can solve the problems of reducing the number of resin column cycles, long extraction time, and increasing the steps of organic weak acid aqueous solution, and achieves convenient operation, simple production equipment, and production conditions easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

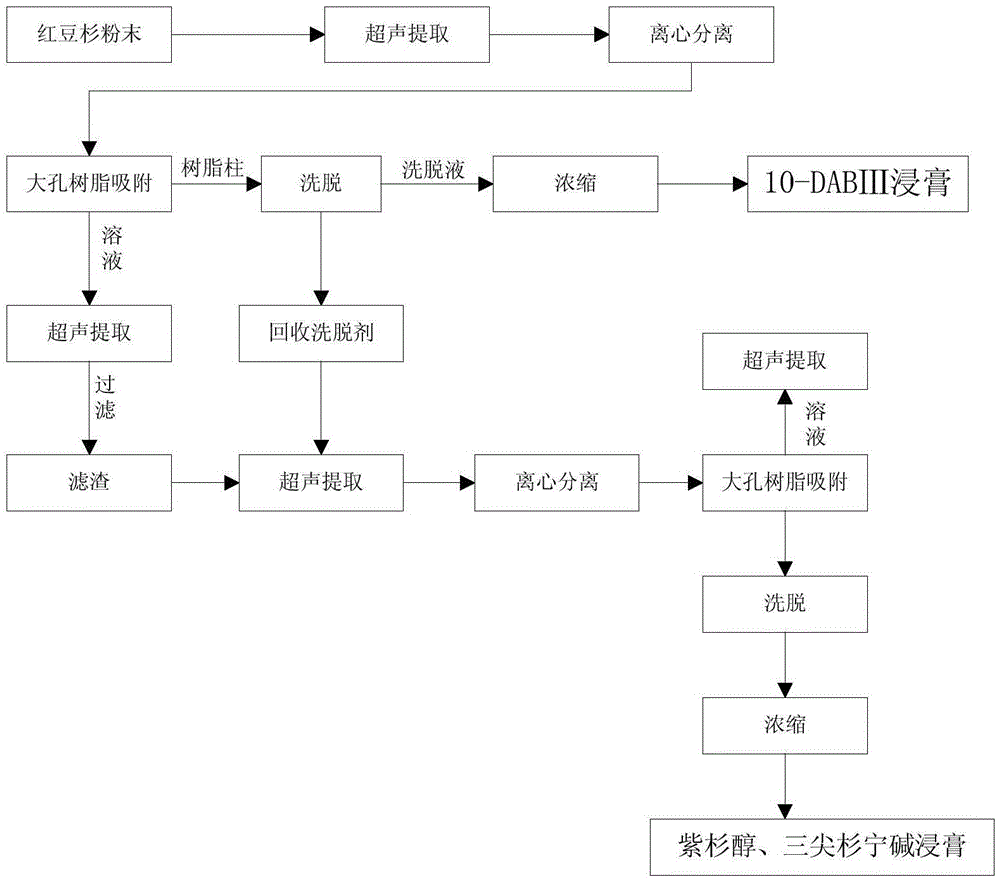

Method used

Image

Examples

Embodiment 1

[0034] (1) Extraction of 10-DABⅢ:

[0035] The branches and leaves of Taxus chinensis are dried in the shade and then crushed to 0.1mm to obtain yew powder; : 5 ratio, add 10-DABⅢ extractant in the yew powder, then carry out ultrasonic extraction under the action of ultrasonic waves with an ultrasonic frequency of 20KHz, and the extract solution enters a rotating speed of 6000r / min after filtering through the filter plate under the ultrasonic extraction tank. Centrifuge in a tubular centrifuge to obtain the centrifugal supernatant and sediment. The sediment is treated as waste residue. The centrifugal supernatant enters the macroporous resin column equipped with AB-8 for adsorption, and the solution after adsorption continues to enter the ultrasonic extraction tank. extract and filter to obtain filtrate and filter residue, and the filtrate is used as the extractant of the next batch of materials, and the filter residue is placed in an ultrasonic extraction tank; the adsorbed res...

Embodiment 2

[0041] (1) Extraction of 10-DABⅢ:

[0042] The branches and leaves of Taxus chinensis are dried in the shade and then crushed to 0.1mm to obtain yew powder; : the ratio of 100, add 10-DABⅢ extractant to the yew powder, and then carry out ultrasonic extraction under the action of ultrasonic waves with an ultrasonic frequency of 50KHz. Centrifuge in a tubular centrifuge to obtain the centrifugal supernatant and sediment. The sediment is treated as waste residue. The centrifugal supernatant enters the macroporous resin column equipped with D101 for adsorption, and the solution after adsorption continues into the ultrasonic extraction tank. The entire ultrasonic extraction time is 6 hours, and then the material in the ultrasonic extraction tank is filtered to obtain the filtrate and filter residue, the filtrate is used as the extractant for the next batch of materials, and the filter residue is placed in the ultrasonic extraction tank; the resin column after adsorption is to be ad...

Embodiment 3

[0048] (1) Extraction of 10-DABⅢ:

[0049] The branches and leaves of Taxus chinensis are dried in the shade and then crushed to 0.5mm to obtain the yew powder; : the ratio of 50, 10-DABⅢ extractant in the yew powder, then carry out ultrasonic extraction under the ultrasonic wave effect of 35KHz in ultrasonic frequency, the total time of ultrasonic treatment is 4 hours, and extracting liquid is carried out through the filter plate under the ultrasonic extraction tank After filtration, it enters a tubular centrifuge with a rotating speed of 10000r / min for centrifugation to obtain the centrifugal supernatant and sediment. The sediment is treated as waste residue, and the supernatant enters the macroporous resin column equipped with HPD300 for adsorption. The solution enters the ultrasonic extraction tank to continue the extraction, and the material in the ultrasonic extraction tank is filtered to obtain the filtrate and filter residue. The filtrate is used as the extractant for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com