An optimization design method for overall volume fracturing of coalbed methane reservoirs

A volume fracturing and optimal design technology, applied in the petroleum field, can solve problems such as the inability to meet the volume fracture characterization of coalbed methane reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following takes a certain coalbed methane reservoir as an example, and describes the embodiment of the present invention in detail in conjunction with the accompanying drawings, for the purpose of schematically illustrating and explaining the present invention, and not limiting the scope of the present invention.

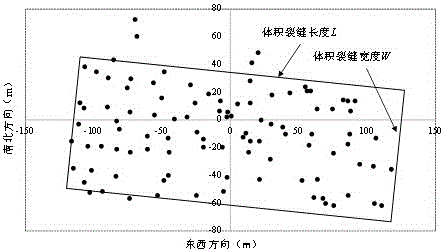

[0053] Step 1. According to the 350×300m rectangular well pattern of the coalbed methane reservoir, the reservoir thickness is 4.6m, and the well spacing and row spacing are extended by 0.5, a well group unit with a size of 700m×600m×4.6m is established. Input the basic reservoir parameters in Table 1, and the gas reservoir parameters in Tables 2 to 4, including basic gas reservoir parameters, natural gas PVT parameters and isothermal adsorption parameters, and finally establish the geological model of the coalbed methane reservoir well group unit (such as figure 1 ).

[0054] Table 1 Reservoir geological parameters of this coalbed methane reservoir

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com