Radiant floor heating pipeline pulse cleaning machine

A technology for pulse cleaning and floor heating pipelines, which is applied in flushing, cleaning of heat transfer devices, household heating, etc. It can solve the problems of reducing indoor heating temperature, small pulse force, and cumbersome operation, so as to extend the service life and solve time-consuming problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

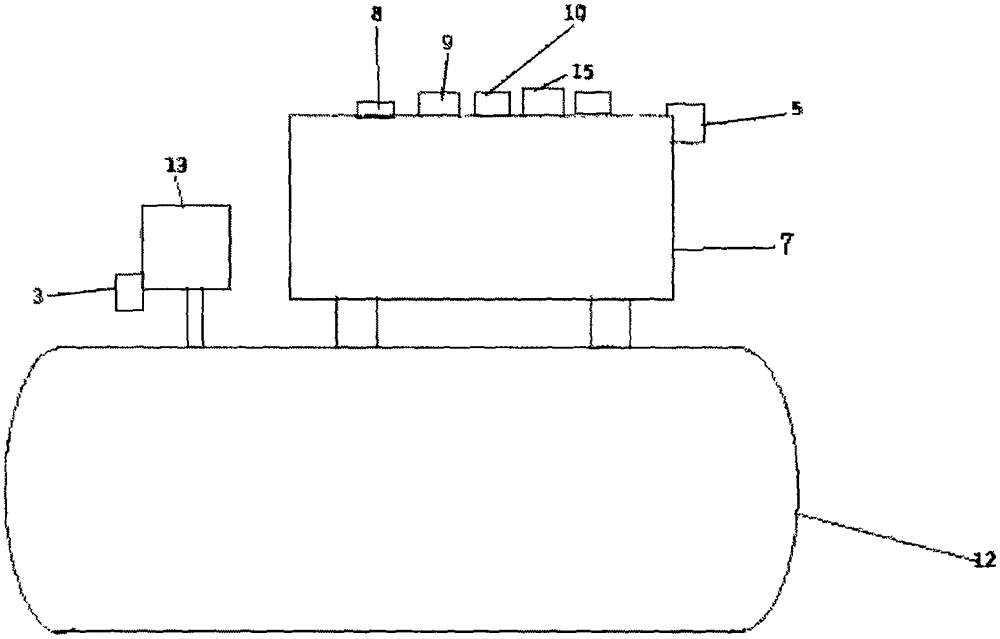

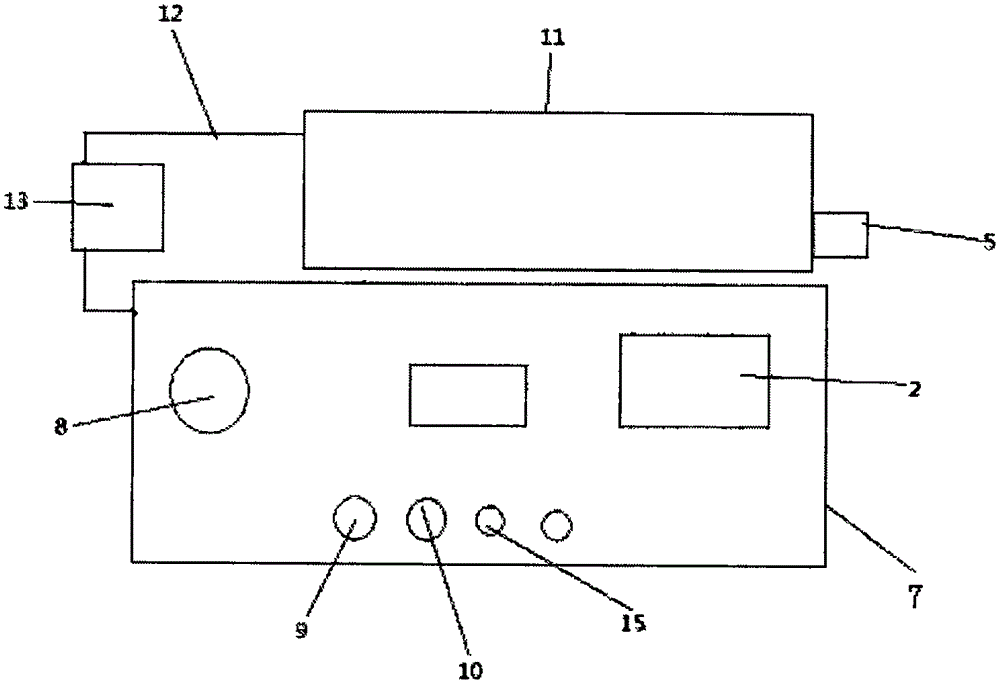

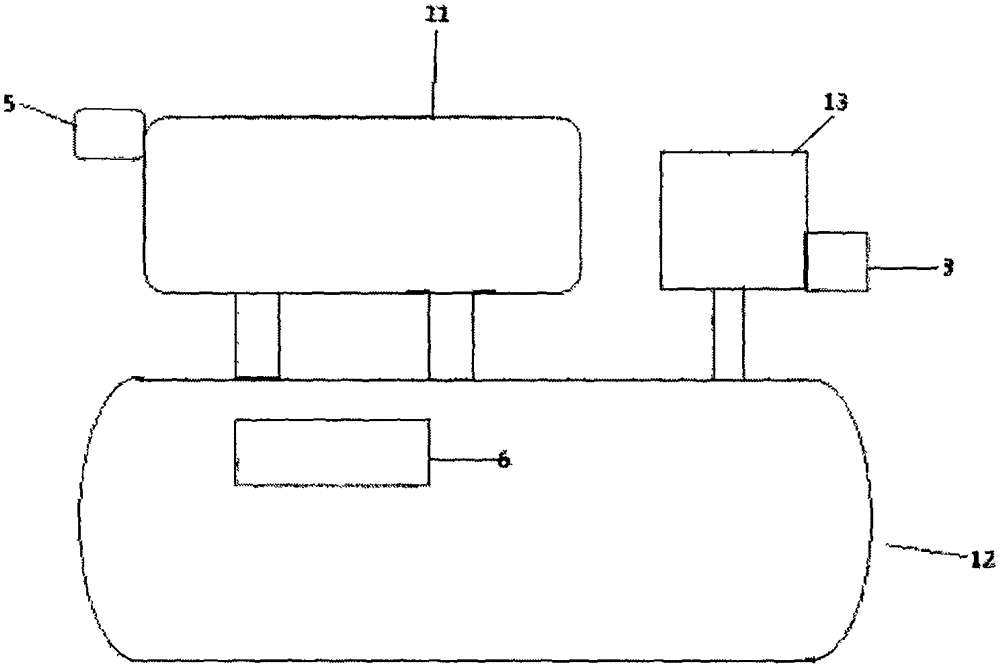

[0020] Such as Figure 1-5 As shown, a floor heating pipeline pulse cleaning machine according to the embodiment of the present invention includes: an air storage tank 12, a pulse generator 7 and an air compressor 11 are installed on the top of the air storage tank 12; a pulse generator 7 is installed on the pulse generator 7 Device internal pressure gauge 8, time relay 2, water inlet indicator light 9, high pressure air indicator light 10, power switch 15, and muffler 5. The gas storage tank stores the high-pressure gas generated by the air compressor, and the high-pressure gas enters the pulse generator through the gas outlet pipe.

[0021] An air compressor switch 13 is installed on the top of the air compressor 11, and a heat exchange fan 4 is installed on the side of the air compressor 11.

[0022] A motor capacitor 6 is installed on the side of the gas storage tank 12, and the motor capacitor helps to start the motor. The gas storage tank pressure gauge 3 is also instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com