Additive manufacturing method and equipment

一种增材制造、主体的技术,应用在增材制造领域,能够解决物体不充分支撑、失败等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

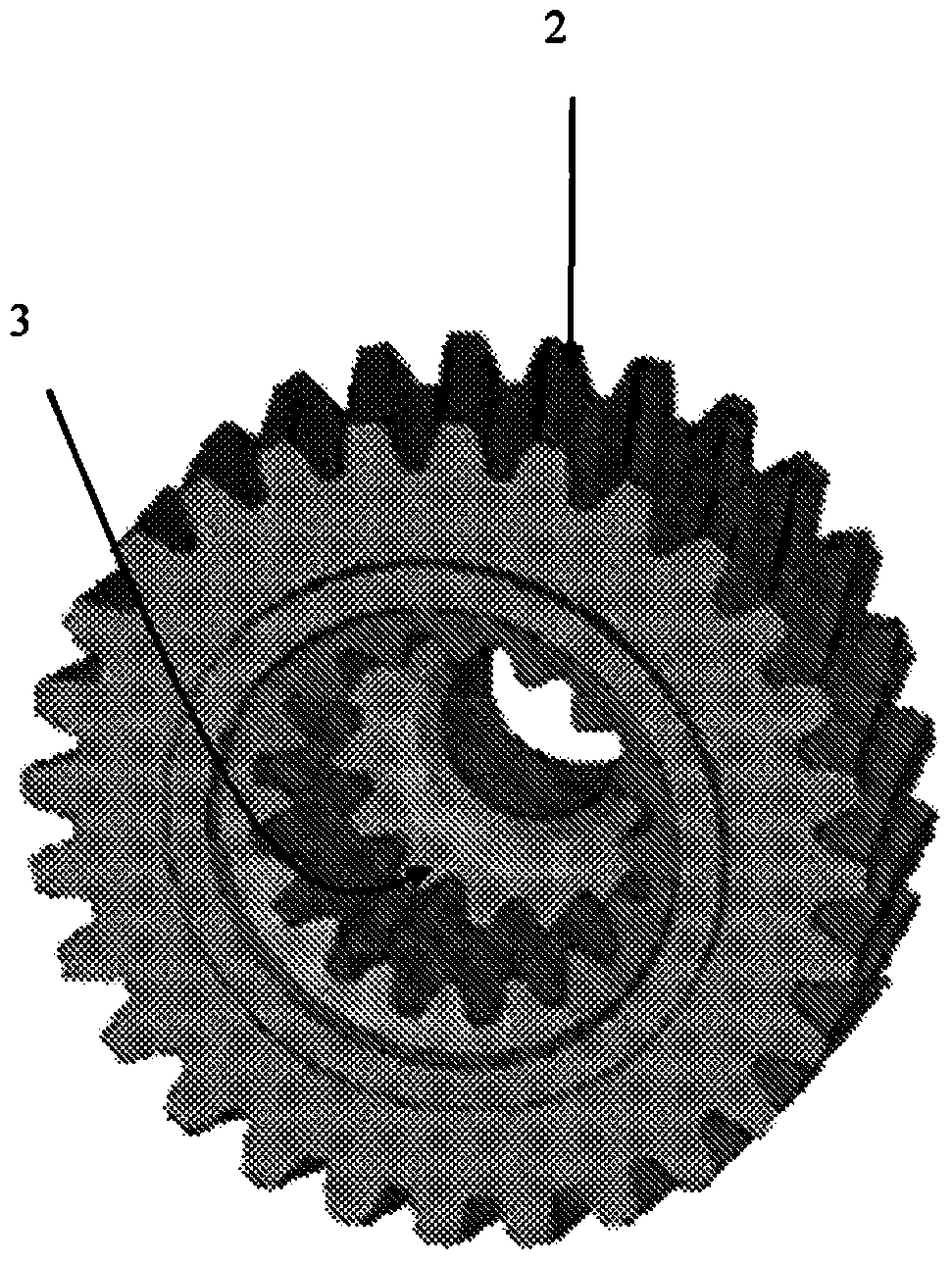

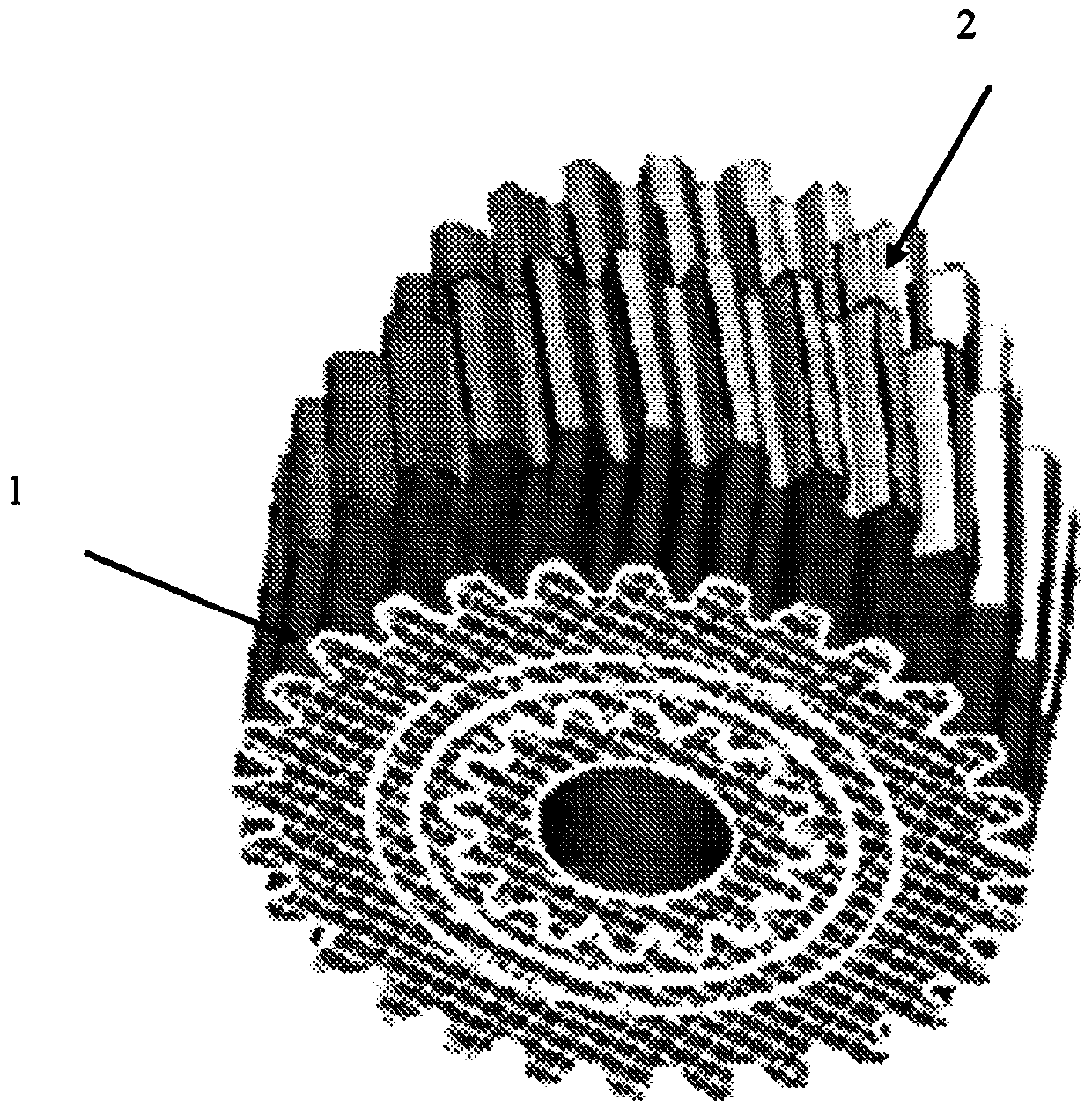

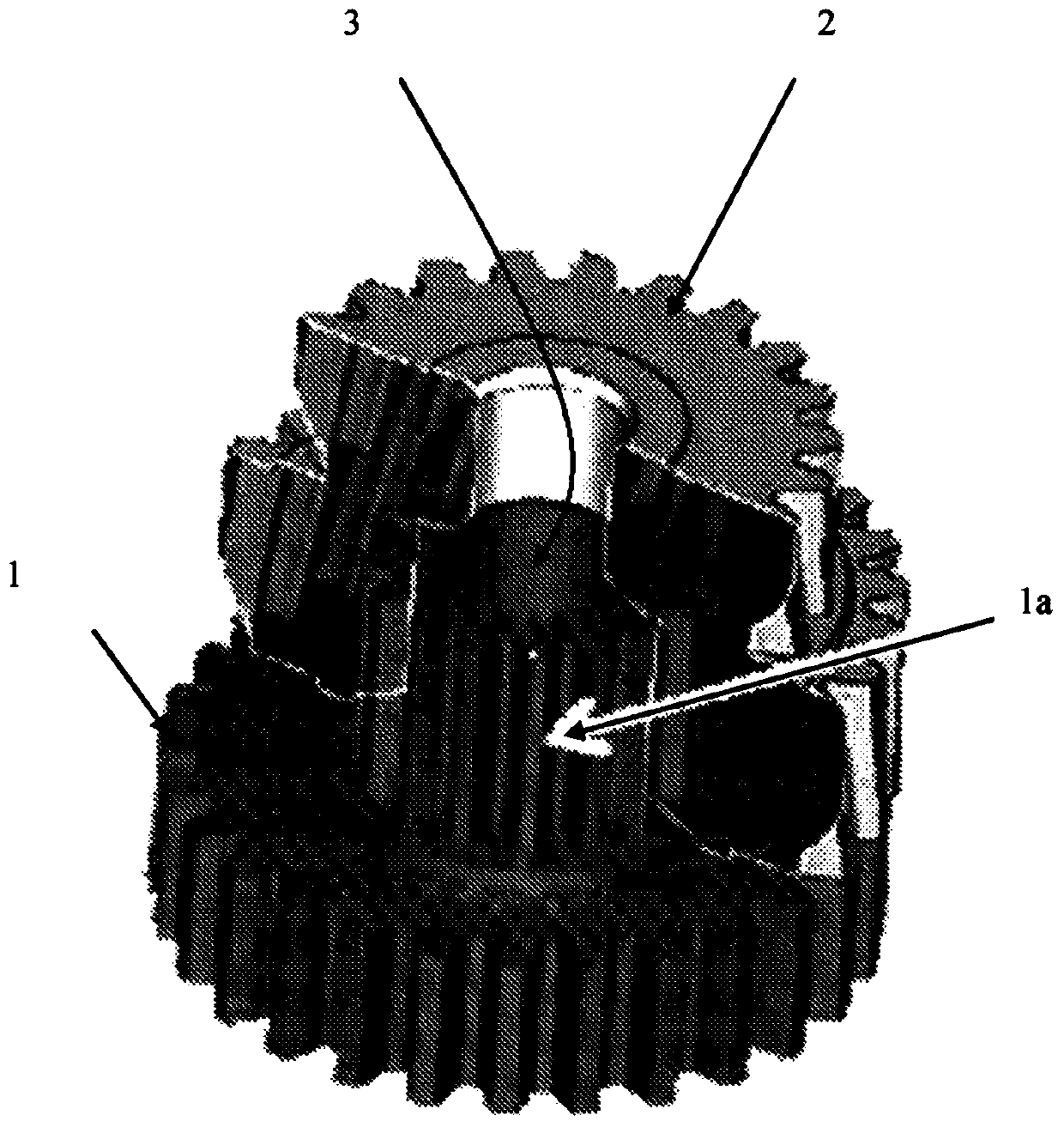

[0048] refer to Figures 2a to 2c A support structure 101 for supporting an object 2 during additive manufacturing (eg SLM or SLS) comprises a plurality of individual supports 105a to 105h for supporting the object. Each support comprises a body 106a to 106h attached to the object by a 2-dimensional pattern of breakable structures 107 that can be broken by applying force to the bodies 106a to 106h . The body 106a to 106h is a block of material that is cured using an SLM or SLS process. exist Figure 2c In , a regular grid pattern of frangible elements 107 is shown for supports 105c, 105d, 105a and 105f. Each support further comprises a further frangible structure 108 which attaches the bodies 106a to 106h to a build platform (not shown).

[0049] The bodies 106a to 106h are arranged to define a gap 112 therebetween into which the bodies 106a to 106h can be moved by an input force. Each gap 112 is sized such that each body 106a-106h has sufficient swing to break the frangi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com