Sheet manufacturing method and manufacturing apparatus

A technology of sheet cutting and vibration suppression, applied in the field of sheet manufacturing, can solve the problems of small elongation of glass, conveying glass web, breaking of glass web, etc., to shorten processing time, improve conveying quality, and prevent interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Reference will now be made in detail to the exemplary embodiments of the present invention taken in conjunction with the accompanying drawings.

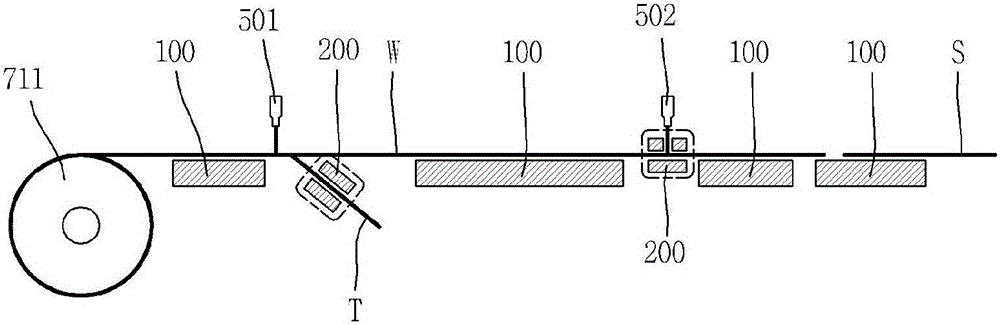

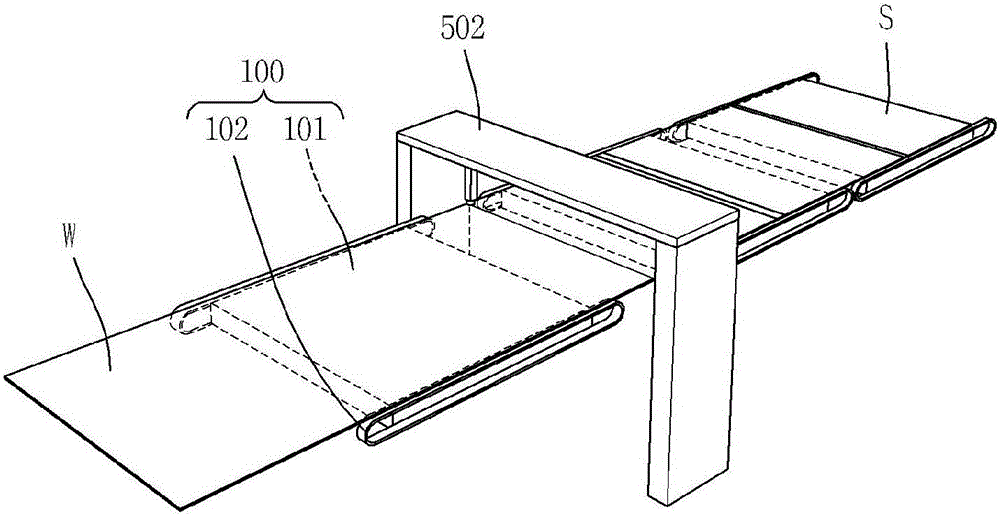

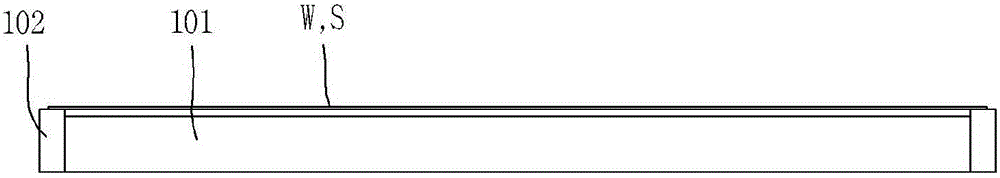

[0024] The present invention relates to a method of manufacturing a sheet. The sheet manufacturing method manufactures a sheet S by cutting an object O supplied in the shape of a web W unwound from a roll.

[0025] For this purpose, the object O supplied in the shape of a web W is conveyed and processed, and the web W is conveyed in a non-contact manner using an ultrasonic vibrator. The effective area of the object O is transferred in a non-contact manner using the ultrasonic non-contact technique disclosed in Korean Patent Application Publication No. 10-2010-0057530. The object O is conveyed in a non-contact manner downstream of the apparatus for producing sheets, wherein a non-contact cutting unit 502 with a laser completely cuts the object O into sheets S which are then conveyed in a non-contact manner to subsequent oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com