peanut planter

A peanut planter and rack technology, applied in the field of agricultural machinery, can solve the problems of increased labor intensity, increased ditching resistance, and large resistance, and achieve the effects of reducing ditching resistance, increasing effective density, and reducing ridge spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

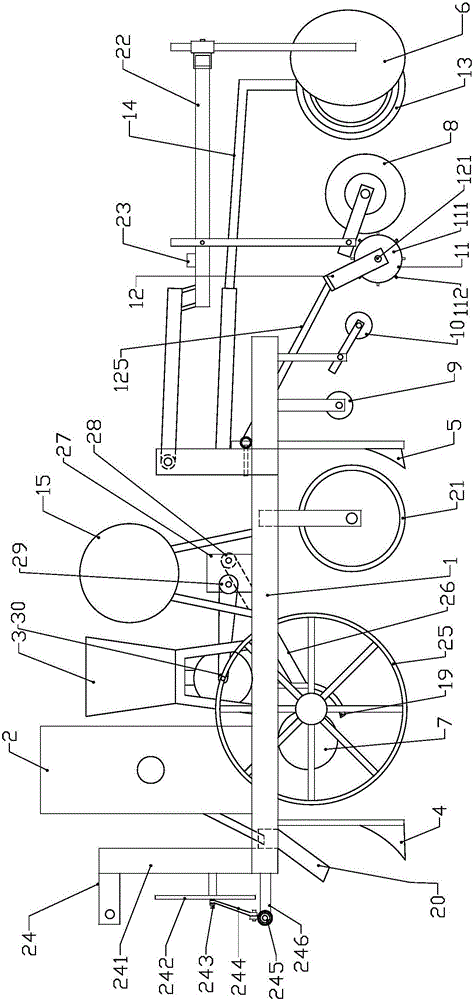

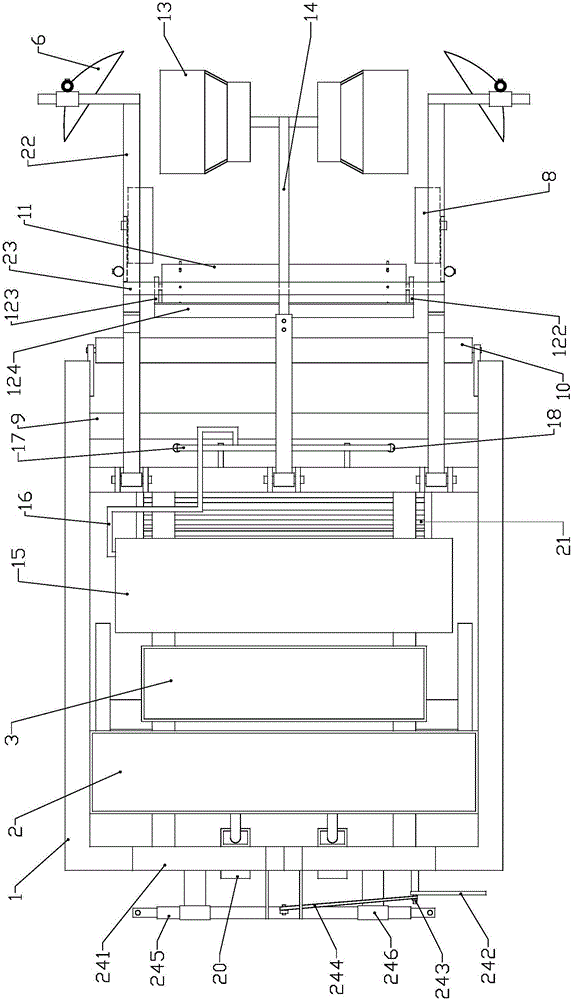

[0014] Refer to the attached figure 1 And attached figure 2 The peanut planter of the present invention is described in detail below.

[0015] Peanut planter of the present invention, its structure comprises frame 1, fertilizer box 2, seed box 3, ridging coulter 4, ditching coulter 5 and covering soil coulter 6, described fertilizer box 2 and seed box 3 respectively Be arranged on the top of frame 1, ridging coulter 4, ditching coulter 5 and covering soil coulter 6 are respectively arranged on the bottom of frame 1, the bottom of described seed box 3 is provided with seed meter 7, described A compaction wheel 8 is arranged between the ditching coulter 5 and the soil covering coulter 6, the film-covering frame 9 is arranged at the rear of the frame 1, and traveling wheels 25 are arranged on both sides of the frame 1, The two road wheels 25 are connected by a road wheel shaft, and the road wheel shaft is provided with a road wheel gear. Output gear 29 is arranged, and outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com