Rotary jet flow aerating agitation device for jet flow type flotation machine

A technology for aeration stirring and flotation machines, which is applied in flotation, solid separation, etc., and can solve problems such as the influence of air suction and the fact that the rotating jet is not suitable for the aeration and agitation device of flotation machines, so as to increase the amount of aeration and improve the separation effect , the effect of enhanced stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

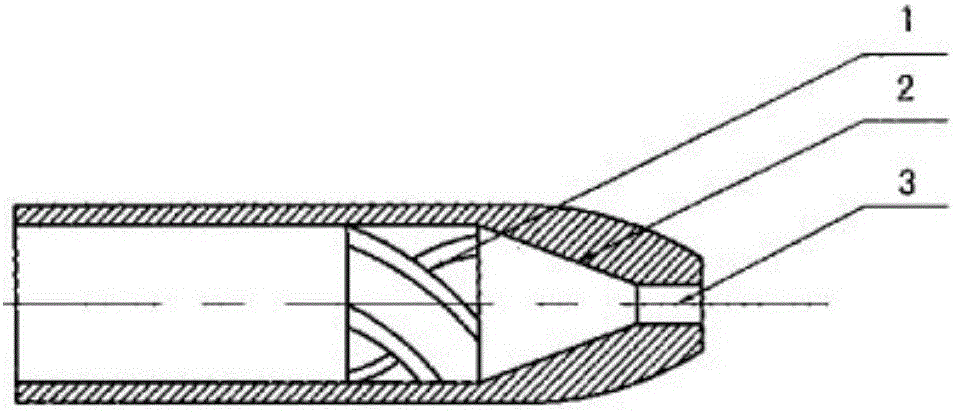

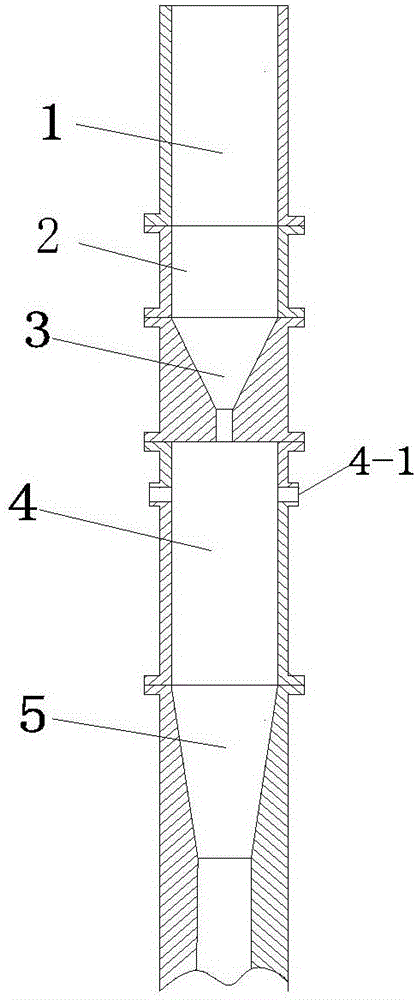

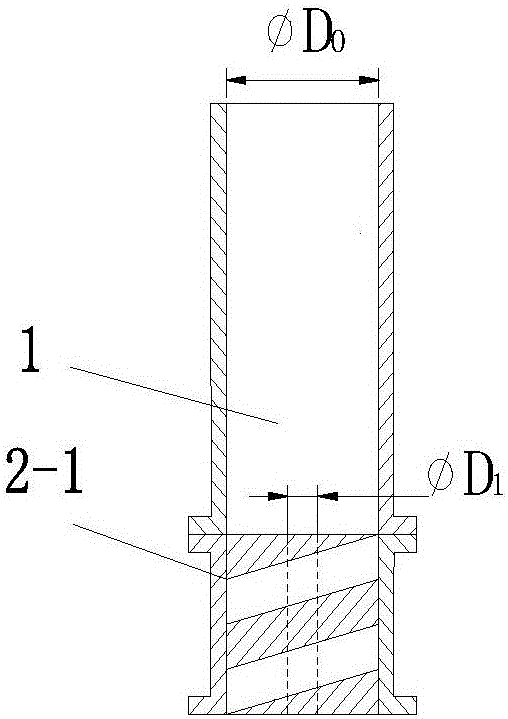

[0028] Embodiment 1: With reference to the schematic diagrams of 2, 3, 4, and 7, the rotary jet inflatable stirring device is as shown in the accompanying drawings, including a feed pipe 1, a spiral body 2-1, a conical nozzle 3, an initial mixing pipe 4, and a throat pipe 5, It is installed coaxially in sequence, and the connection method is bolted connection. The spiral body 2-1 is a cylindrical entity with a rectangular thread groove, and a straight-through circular opening is opened in the axial direction. The rectangular thread groove is built and fixed in the straight pipe, and its major diameter is equal to the diameter D of the feeding pipe. 0 , the path is d 0 , the axial free path is D 1 , the diameter of the conical nozzle is D 2 , and d 0 >D 1 >D 2 , its pitch P is 0.25D 0 ~0.5D 0 , The helix angle is 10-30°, and the number of turns is 0.5-1.5 turns.

[0029]When working, a single feeding pump can feed into one or more rotating jet aeration stirring devices ...

Embodiment 2

[0030] Embodiment 2: Referring to the schematic diagrams of 2, 5, 6, and 7, the rotary jet aeration stirring device is as shown in the accompanying drawings, including a feeding pipe 1, a rotating body 2-2, a conical nozzle 3, an initial mixing pipe 4, and a throat 5. Install coaxially in sequence, and the connection method is bolted connection. The spin body 2-2 is provided with a spin block 2-21 inside. The center of the spin body 2-21 is an axial circular flow channel, the diameter of the flow channel is equal to the diameter of the inlet of the conical nozzle 3, and the spin block 2-21 is distributed symmetrically and tangentially along the outer ring of the axial circular flow channel, forming a groove The flow channel is tangential, and the swirl block 2-21 is not inscribed with the wall of the straight pipe, and the number of swirl blocks is 4-8.

[0031] When working, a single feeding pump can feed into one or more rotating jet aeration stirring devices at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com