Heat-insulation vermiculite artificial culture stone and preparation method thereof

A technology of thermal insulation and cultural stone, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of application limitation and low strength, and achieve the effects of good thermal insulation, high strength, and scientific composition ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1, prepare the mold: use natural or pre-processed stone models to reproduce the mold according to the needs of the market and customers;

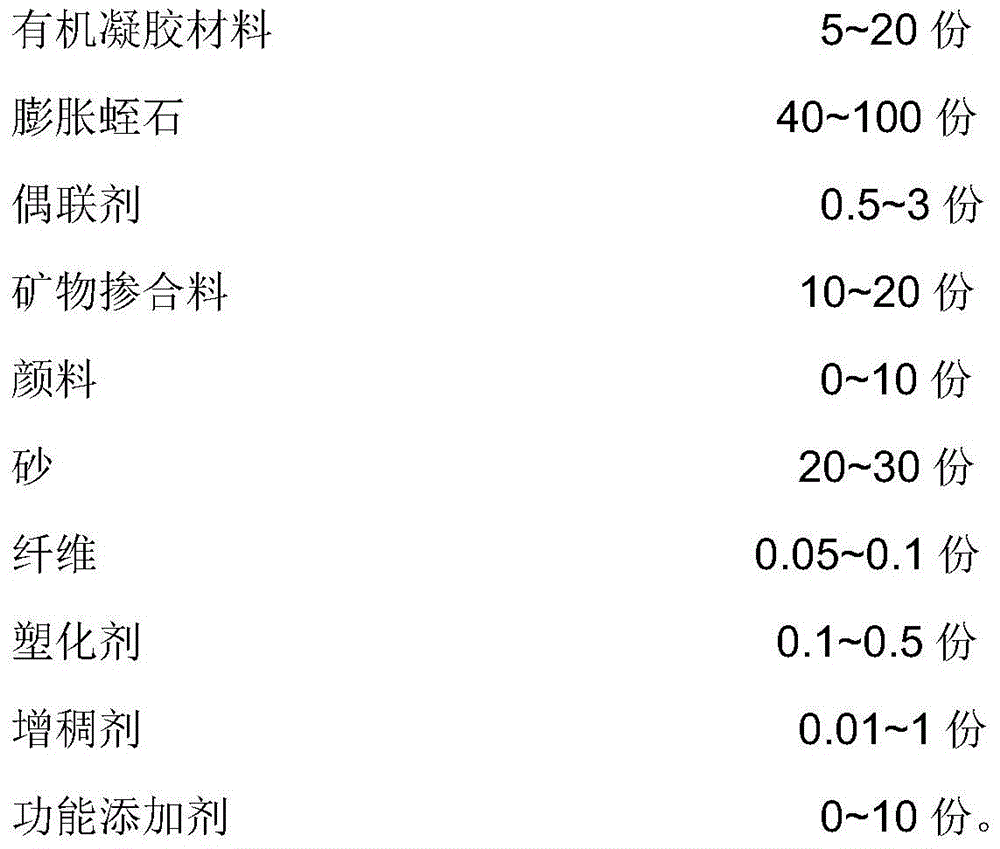

[0036] Step 2, preparing the structural layer slurry, wherein the components of the structural layer slurry include:

[0037]

[0038]

[0039] Vermiculite modification: Add the coupling agent to the weighed water under stirring, then add expanded vermiculite, stir evenly, and then add organic film formers;

[0040] Then add plasticizers, functional additives, fibers, pigments, sand, mineral admixtures and inorganic gelling materials in sequence, and each material is added at an interval of 2 minutes;

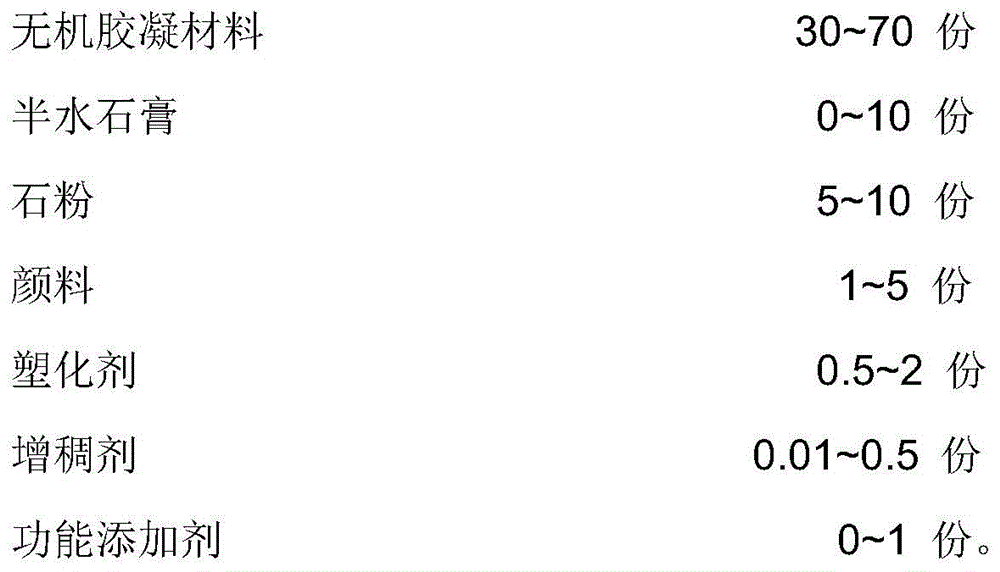

[0041] Step 3, prepare the color layer

[0042] Wherein the component of color layer slurry comprises:

[0043]

[0044] Step 4, fully spraying the prepared color layer slurry on the inner surface of the product mold for coloring to form a color layer;

[0045] Step 5, pouring the prepared bottom layer slurry in the m...

Embodiment 2

[0049] Step 1, prepare the mold: use natural or pre-processed stone models to reproduce the mold according to the needs of the market and customers;

[0050] Step 2, the structural layer slurry, wherein the components of the structural layer slurry include:

[0051]

[0052] Methods as below:

[0053] Vermiculite modification: Add the coupling agent to the weighed water under stirring, then add expanded vermiculite, stir evenly, and then add organic film formers;

[0054] Add plasticizers, functional additives, fibers, pigments, sand, mineral admixtures and inorganic gelling materials in sequence, with an interval of 2 minutes between each material addition;

[0055] Step 3, prepare color layer paste

[0056] Wherein the component of color layer slurry comprises:

[0057]

[0058] Step 4, fully spraying the prepared color layer slurry on the inner surface of the product mold for coloring to form a color layer;

[0059] Step 5, pouring the prepared bottom layer slurry...

Embodiment 3

[0063]Step 1, prepare the mold: use natural or pre-processed stone models to reproduce the mold according to the needs of the market and customers;

[0064] Step 2, preparing the structural layer slurry, wherein the components of the structural layer slurry include:

[0065]

[0066] The preparation method of the structural layer slurry is as follows:

[0067] Vermiculite modification: Add the coupling agent to the weighed water under stirring, then add expanded vermiculite, stir evenly, and then add organic film formers;

[0068] Add plasticizers, functional additives, fibers, pigments, sand, mineral admixtures and inorganic gelling materials in sequence, with an interval of 2 minutes between each material addition;

[0069] Step 3, prepare color layer paste

[0070] Wherein the component of color layer slurry comprises:

[0071]

[0072]

[0073] Step 4, fully spraying the prepared color layer slurry on the inner surface of the product mold for coloring to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com