Alumite sticky layer coating containing acrylic monomers and using method thereof

An acrylic, anodized aluminum technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as affecting the effect of hot stamping, and achieve the effect of overcoming false hot stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

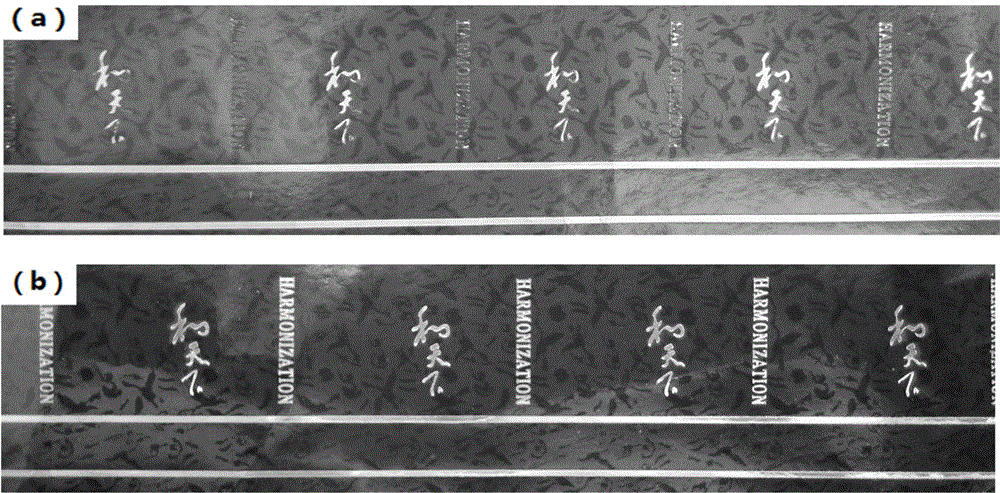

Image

Examples

Embodiment 1

[0026] The components of the anodized aluminum bonding layer coating can be:

[0027] Hyperbranched polyurethane modified acrylate: 40 parts;

[0028] 300 mesh silica powder: 1 part;

[0029] 99.8% rosin: 1 part;

[0030] 50% butanone, 20% ethyl acetate, 30% n-butanol: 50 parts.

[0031] Dissolve the acrylic acid monomer, silica powder and rosin in the dispersion solvent in the order listed by the materials, and mix each component according to a certain mass ratio. Using a planetary mixer, the stirring speed is 500m / min, and the stirring time is 0.5h. , to obtain the adhesive layer coating.

[0032] Use a professional coating machine (SDC1500E, Songde Packaging Machinery Co., Ltd., Zhongshan City, Guangdong Province) to evenly coat the bonding layer coating on the anodized aluminum vacuum aluminized layer, and enter the drying tunnel through the conveyor belt to dry. The coating speed is set at 70m / min, the temperature of the drying tunnel adopts a gradient temperature st...

Embodiment 2

[0034] The components of the anodized aluminum bonding layer coating can be:

[0035] Hyperbranched polyurethane modified acrylate: 60 parts;

[0036] 800 mesh silica powder: 4 parts;

[0037] 99.9% rosin: 6 parts;

[0038] 50% butanone, 20% ethyl acetate, 30% n-butanol: 70 parts.

[0039] Dissolve the acrylic acid monomer, silicon dioxide powder and rosin in the dispersion solvent in the order listed by the materials, each component is proportioned according to a certain number of parts by mass, using a planetary mixer, the stirring speed is 2000m / min, and the stirring time is 2h. The tie coat coating can be obtained.

[0040] Use a professional coating machine (SDC1500E, Songde Packaging Machinery Co., Ltd., Zhongshan City, Guangdong Province) to evenly coat the bonding layer coating on the anodized aluminum vacuum aluminized layer, and enter the drying tunnel through the conveyor belt to dry. The coating speed is set at 130m / min, the temperature of the drying tunnel ad...

Embodiment 3

[0042] The components of the anodized aluminum bonding layer coating can be in parts by mass:

[0043] Hyperbranched polyurethane modified acrylate: 55 parts;

[0044] 500 mesh silica powder: 3 parts;

[0045] 99.9% rosin: 4 parts;

[0046] 50% butanone, 20% ethyl acetate, 30% n-butanol: 60 parts.

[0047] Dissolve the acrylic acid monomer, silica powder and rosin in the dispersion solvent in the order listed by the materials, and mix each component according to a certain mass ratio. Using a planetary mixer, the stirring speed is 500~2000m / min, and the stirring time is 0.5~2h, the adhesive layer coating can be obtained.

[0048] Use a professional coating machine (SDC1500E, Songde Packaging Machinery Co., Ltd., Zhongshan City, Guangdong Province) to evenly coat the bonding layer coating on the anodized aluminum vacuum aluminized layer, and enter the drying tunnel through the conveyor belt to dry. The coating speed is set at 110m / min, the temperature of the drying tunnel ado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com