Preparation method of high-thermal-conductivity aluminum base graphene composite material

A composite material and graphene technology, applied in the field of material surface treatment, can solve the problem of insufficient thermal conductivity of metals, achieve the effect of easy operation of instruments and equipment, simple process, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

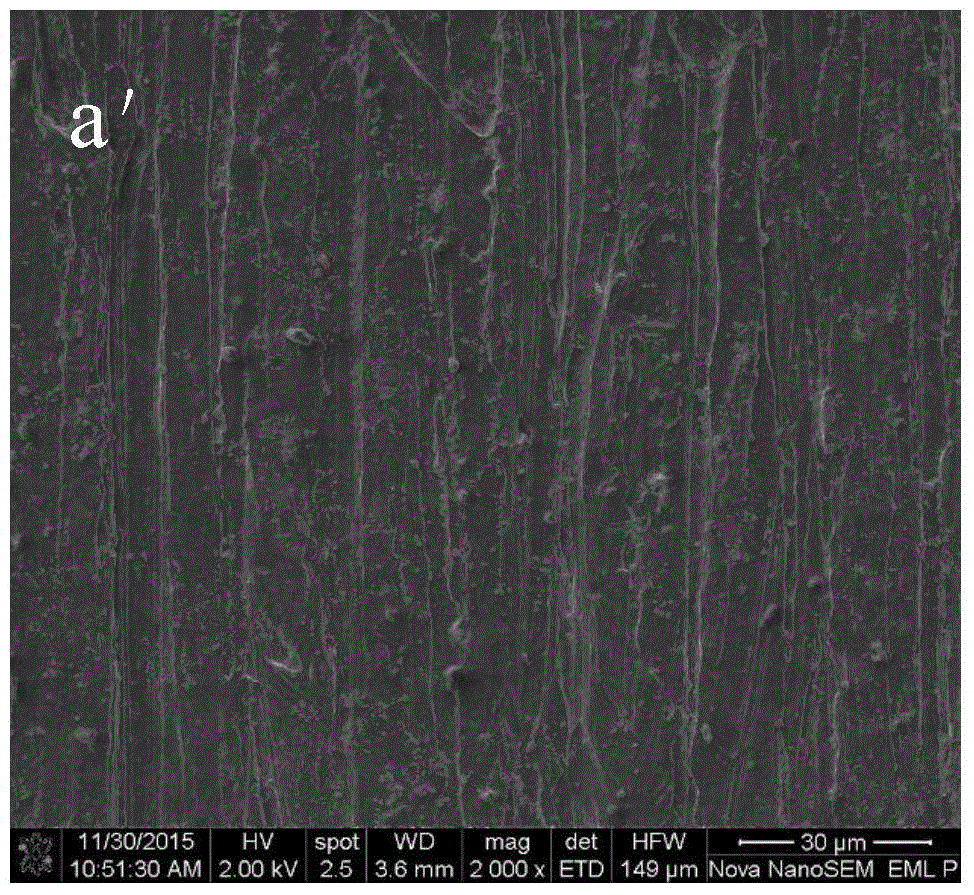

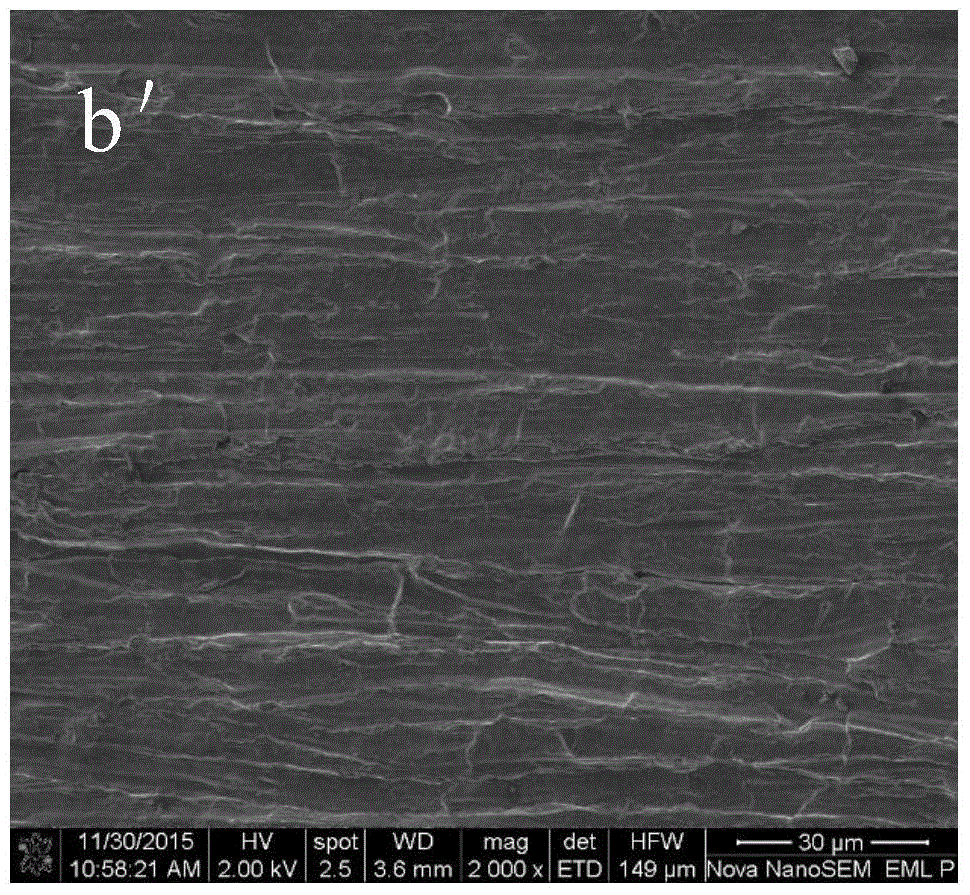

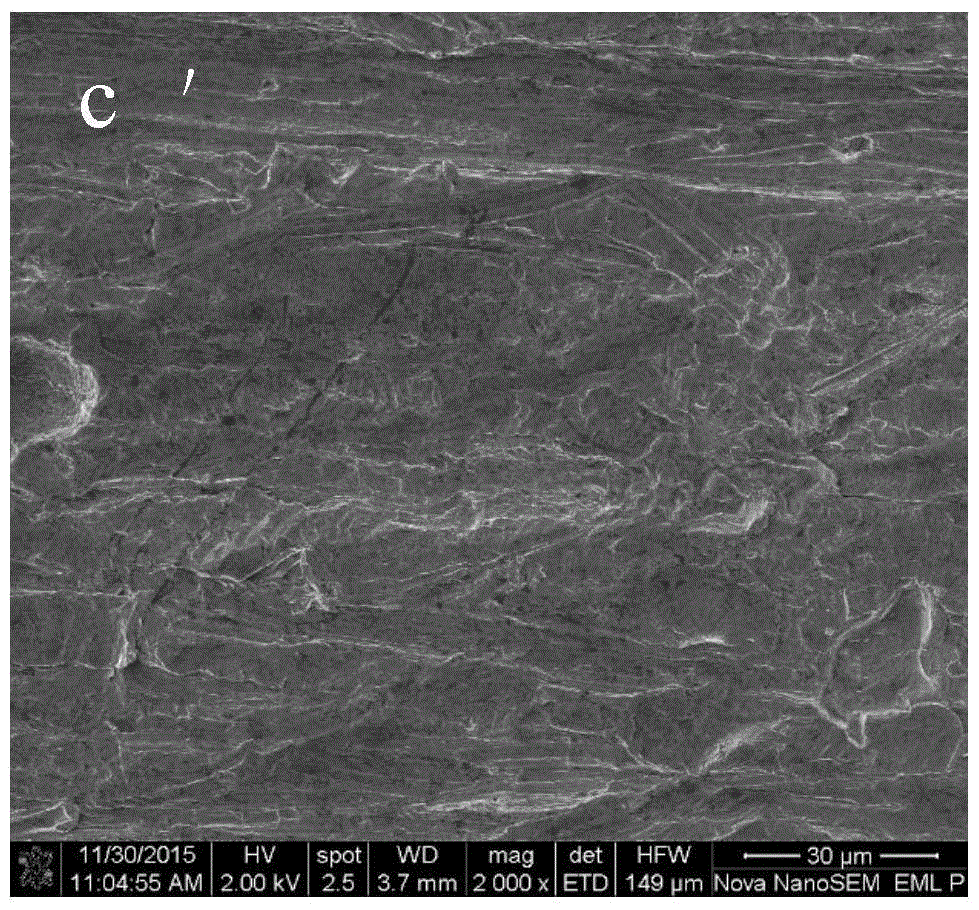

Image

Examples

Embodiment 1

[0025] (1) Prepare dopamine into a 20 mg / mL aqueous solution with distilled water, and adjust its pH to 8.5 with NaOH solution to obtain a dopamine aqueous solution; place graphene oxide in distilled water, and then ultrasonicate for 4 hours to form a 0.5 mg / mL oxidation solution. Graphene aqueous solution;

[0026] (2) The aluminum sheet is ultrasonically cleaned in ethanol, acetone, and ethanol for 5 minutes respectively to remove the oil stain on the surface of the aluminum sheet;

[0027] (3) Immerse the cleaned aluminum sheet vertically in the dopamine aqueous solution, and let it stand for 60 minutes; after the aluminum sheet is taken out from the dopamine aqueous solution, wash it with distilled water, then vertically immerse the aluminum sheet in the graphene oxide aqueous solution, and let it stand React for 3 hours; take the aluminum sheet out of the graphene oxide aqueous solution, wash it with distilled water, put the aluminum sheet flat on a petri dish, and put it...

Embodiment 2

[0035] (1) Prepare dopamine into a 20 mg / mL aqueous solution with distilled water, and adjust its pH to 8.5 with NaOH solution to obtain a dopamine aqueous solution; place graphene oxide in distilled water, and then ultrasonicate for 4 hours to form a 0.5 mg / mL oxidation solution. Graphene aqueous solution;

[0036] (2) The aluminum sheet is ultrasonically cleaned in ethanol, acetone, and ethanol for 5 minutes respectively to remove the oil stain on the surface of the aluminum sheet;

[0037] (3) Immerse the cleaned aluminum sheet vertically in the dopamine aqueous solution and let it stand for reaction for 40 minutes; after the aluminum sheet is taken out from the dopamine aqueous solution, wash it with distilled water, then vertically immerse the cleaned aluminum sheet in the graphene oxide aqueous solution , standing for reaction for 4 hours; take out the aluminum flake from the graphene oxide aqueous solution, wash it with distilled water to obtain the aluminum flake I, pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com