Construction plant for repairing and strengthening tunnel lining structures

A tunnel and lining technology, applied in tunnel lining, shaft lining, mining equipment, etc., can solve the problems of difficult construction, long construction period, and small construction space for workers, and achieve labor cost saving, good engineering adaptability, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

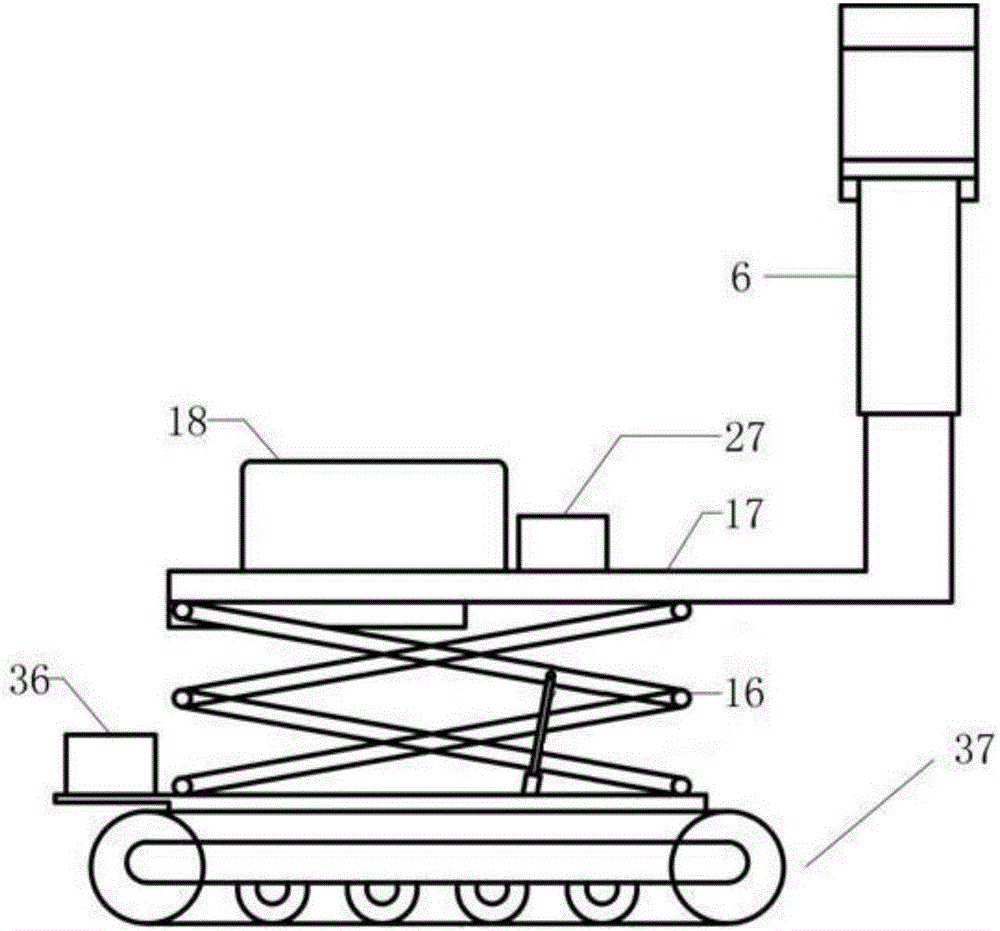

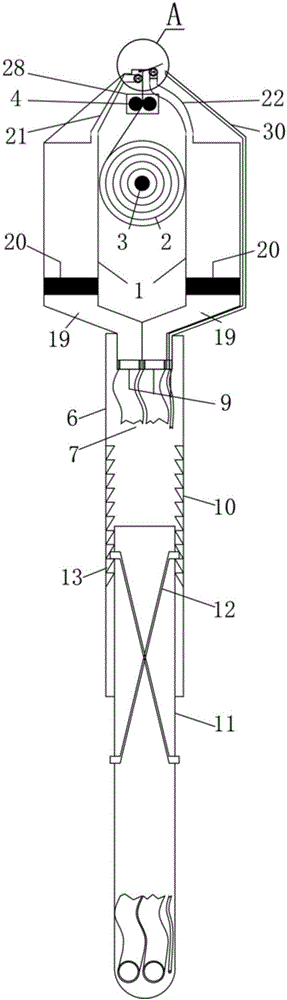

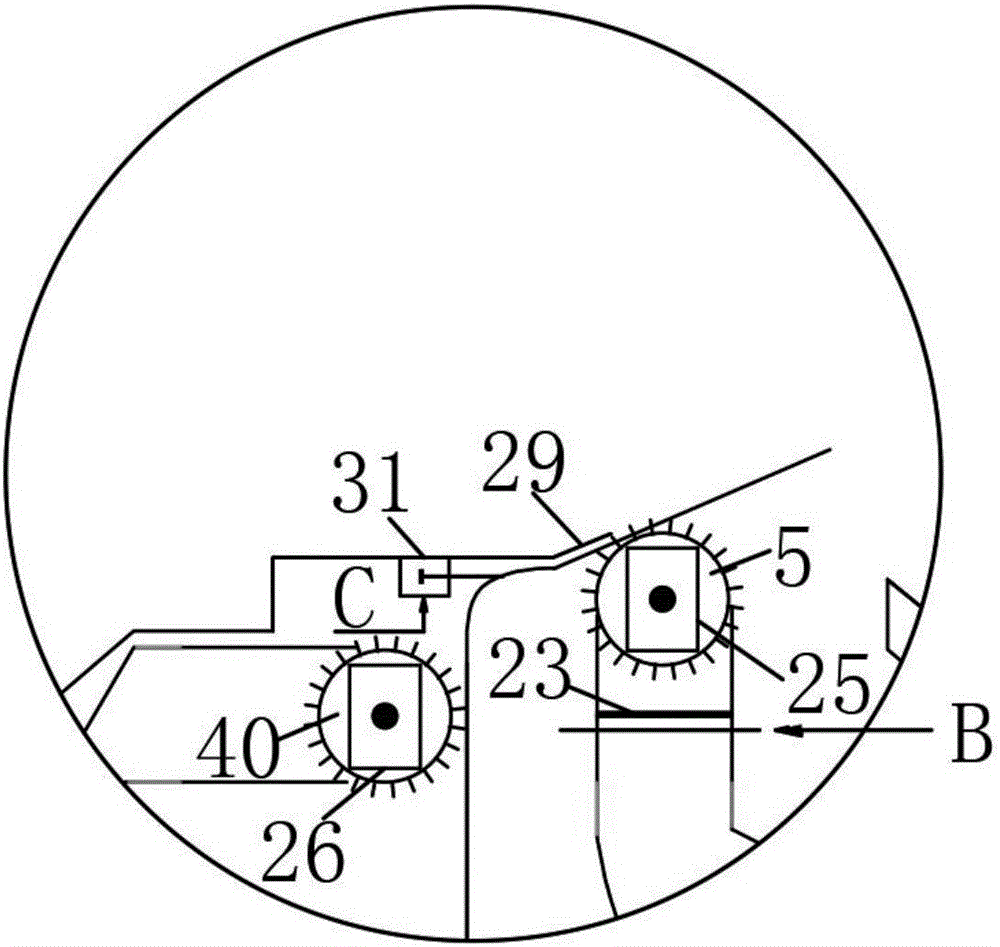

[0031] Such as figure 1 As shown, a tunnel lining structure repair and reinforcement construction equipment includes a traveling device 37 , a circumferential construction device, a lifting device 16 , a control device 36 , and a driving device 27 . Both the lifting device 16 and the control device 36 are installed on the traveling device 37, the lifting device 16 has a lifting platform 17, and the control device 36 is used to control the normal operation of each executive component. The driving device 27 is installed on the lifting platform 17, and the hoop construction device is installed on the hoisting platform 17 through the rotation of the pin shaft structure and is connected with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com