A tunnel dust removal vehicle with a drawer-type dust collection cabin and its use method

A drawer-type, dust-removing truck technology, used in dust-proofing, earth-moving drilling, safety devices, etc., can solve the problems of not being able to completely remove dust and the operation effect is not good enough, meet the requirements of high-efficiency operation, meet the requirements of small radius, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

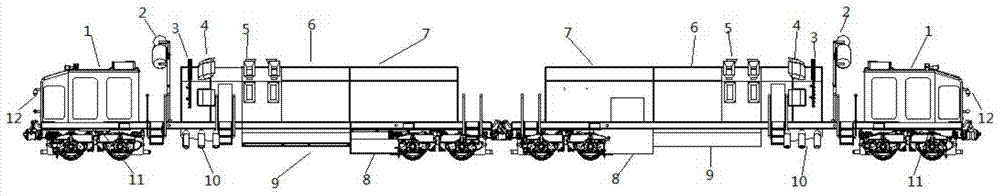

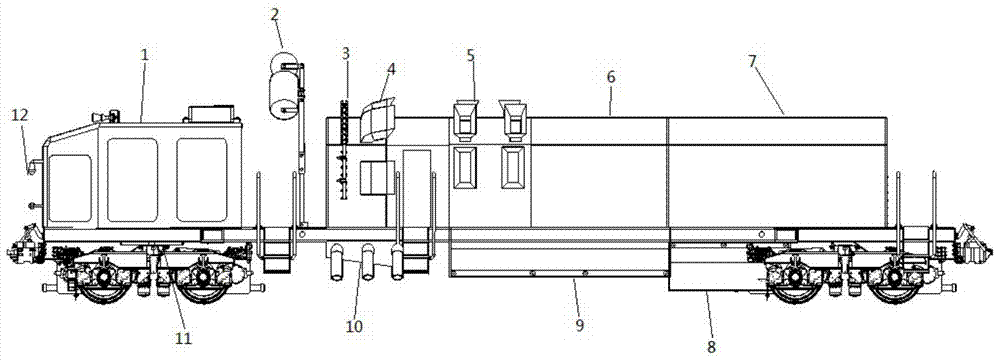

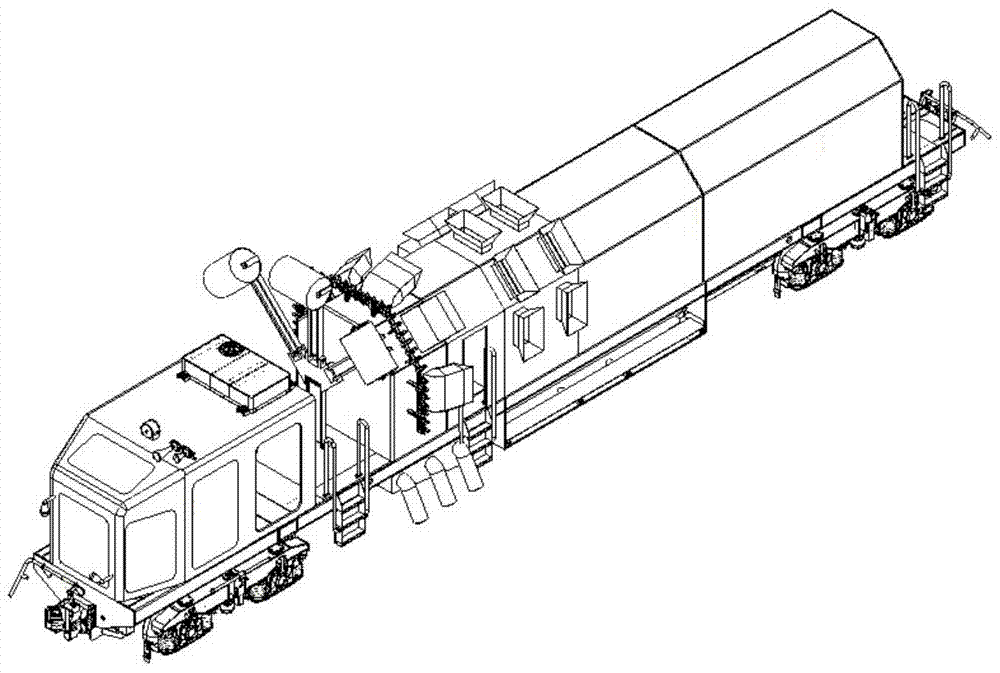

[0066] Embodiment 1.1: tunnel dedusting vehicle, such as Figure 1-11 As shown, it includes two operating vehicles, and the two operating vehicles are symmetrically arranged with respect to the transverse center line of the operating vehicle. The front end of the upper frame of the operating vehicle is provided with a driver's cab 1, and the frame behind the driver's cab 1 is provided with rollers. Hairbrush 2, the lower part of the vehicle frame behind the roller brush 2 is sequentially equipped with a ballast bed dirt suction cabin 10, a dirt suction box dirt collection cabin 9 and a spare dirt collection cabin 8, the vehicle frame behind the roller hair brush 2 The upper part is provided with an air spray head 3, a large air volume air outlet 4, and a large air volume suction port 5 in sequence from the front right to the rear, and the dust filter cabin 6, water storage tank 7, and roller brush 2 are sequentially installed on the frame behind the large air volume suction por...

Embodiment 12

[0093] Embodiment 1.2: Tunnel dedusting vehicle, with embodiment 1.1, difference is: described roller hairbrush horizontal single row 5.

[0094] The working method of the tunnel dedusting vehicle provided by the above-mentioned embodiment is: the tunnel dedusting vehicle is connected and operated to the road section to be operated, firstly the roller brush 2 is stretched out, and the pressure sensor installed at the retractable hydraulic support rod detects the roller The pressure on the brush 2 will automatically stop applying pressure to the roller brush 2 when the pressure value is greater than 0.1KPa, and the roller brush 2 will automatically rotate to clean the working surface; The bracket drives the jet head 3 to stretch out, and the optical rangefinder installed on the jet head bracket detects the distance between the jet head 3 and the working surface. The head 3 starts to impact the work surface with high-pressure airflow, and at the same time, the air outlet 4 with a ...

Embodiment 31

[0097] Embodiment 3.1: a kind of tunnel dedusting method, it comprises:

[0098] A. The three-dimensional laser detector at the front end of the tunnel dust removal vehicle scans the structure and facilities of the tunnel to be operated in an all-round way;

[0099] B. Transmit the scanned data to the vehicle industrial computer;

[0100] C. The industrial computer controls the extension of the roller brush. At the same time, the pressure sensor installed on the telescopic hydraulic support rod detects the pressure on the roller brush. When the pressure value is greater than 0.1KPa, it automatically stops applying pressure to the roller brush 2. The roller The brush 2 starts to roll backwards to clean the working surface and throw the dust to the rear of the car body;

[0101] D. Air nozzle 3 sprays air to perform secondary dusting on the top and walls of the tunnel;

[0102] E. The large-flow blowing port 4 blows air to spray the dust particles backwards, and at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com