Gearbox device for eight-station cold header

A gearbox and cold heading machine technology, which is applied to the driving device of the forging press, transmission device parts, mechanical equipment, etc., can solve the problems of shortened service life of the gearbox, aggravated wear rate between gears, frequent maintenance times, etc., to achieve extended The effect of long service life, vibration prevention and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

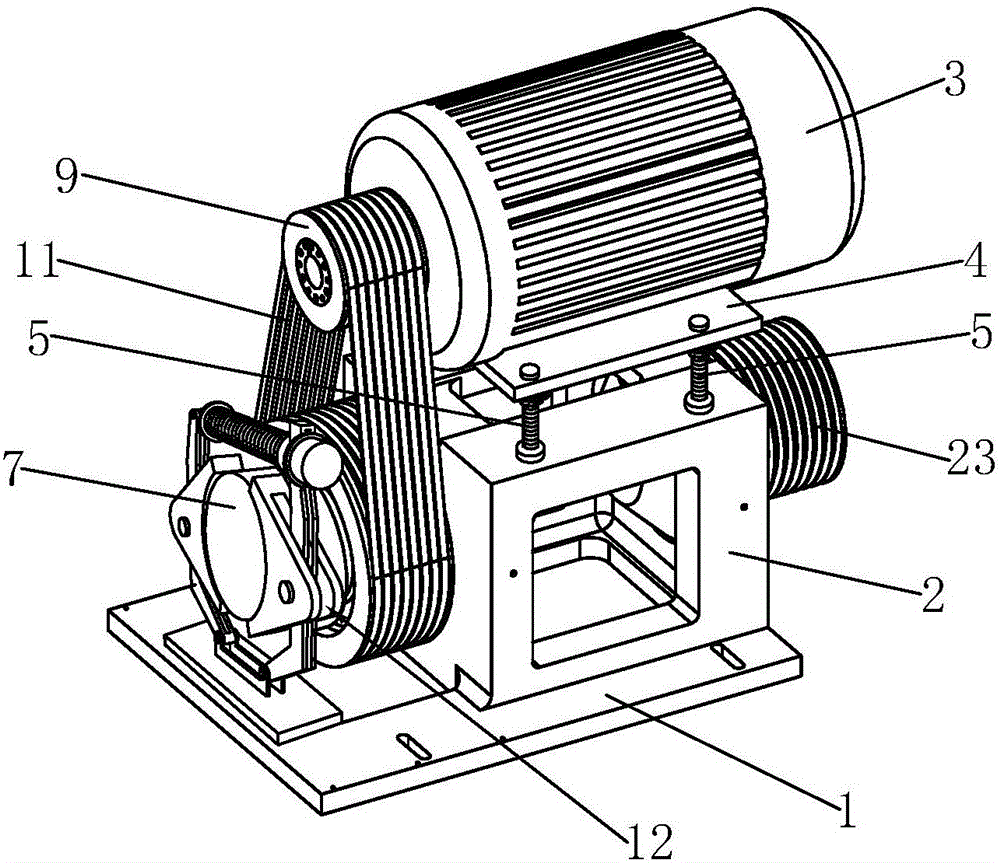

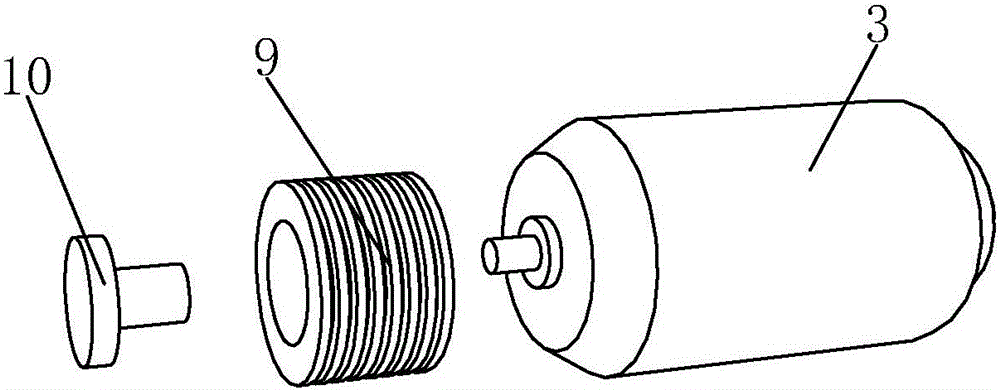

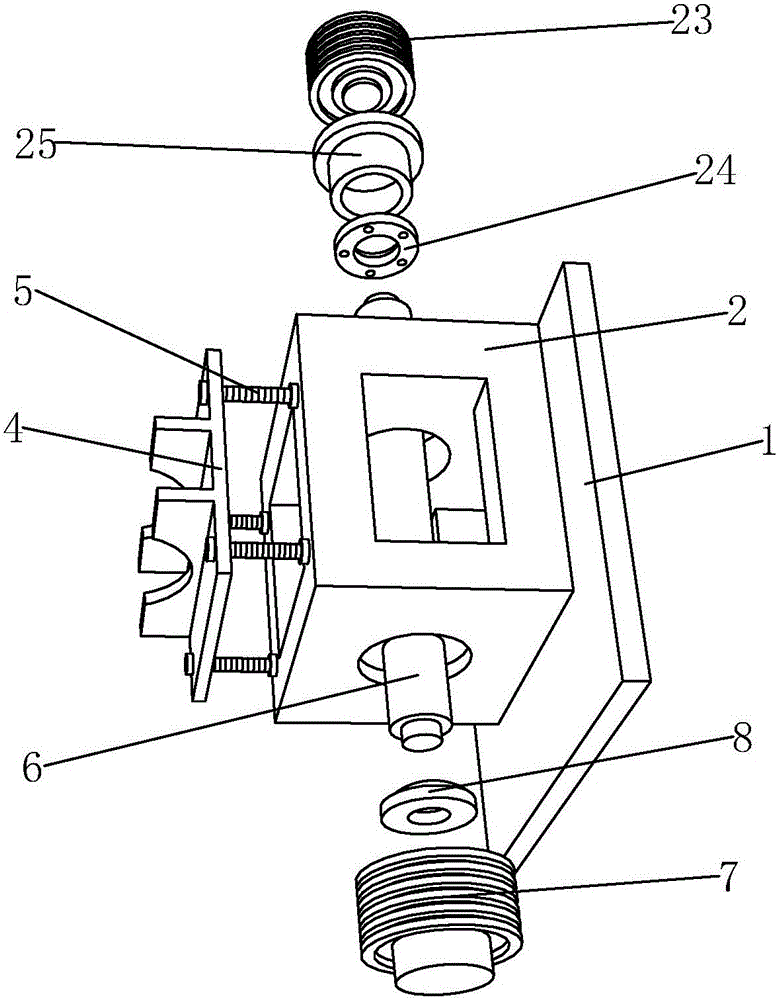

[0030] Such as Figure 1 to Figure 6As shown, it is the gearbox device of the eight-station cold heading machine of the present invention, including an installation platform 1, a gearbox body 2 and a main motor 3, and the gearbox body 2 is arranged on the installation platform 1. In order to reduce weight, the gearbox body 2 The whole body is made of light aluminum material, and the surface is treated with professional electroplating and baking paint, which is smooth, beautiful and stable. The gearbox body 2 is provided with a fixed base 4, the fixed base 4 is provided with a locking protrusion 41, the main motor 3 is located on the locking protrusion 41, the main motor 3 is stuck on the fixed base 4, and the stability High, and easy to install, prevent the main motor 3 from vibrating during work, and ensure work efficiency. Be provided with spring screw rod 5 between gearbox body 2 and fixed base 4, spring screw rod 5 is evenly distributed on the four corners of fixed base 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com