A system and method for adjusting the air temperature at the inlet of a coal mill by using water supply

A coal mill and water supply technology, applied in the control system, combustion method, supplementary water supply, etc., can solve the problems of inefficient utilization of boilers, inability to improve boiler thermal efficiency, etc. Short length to avoid the effect of inefficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

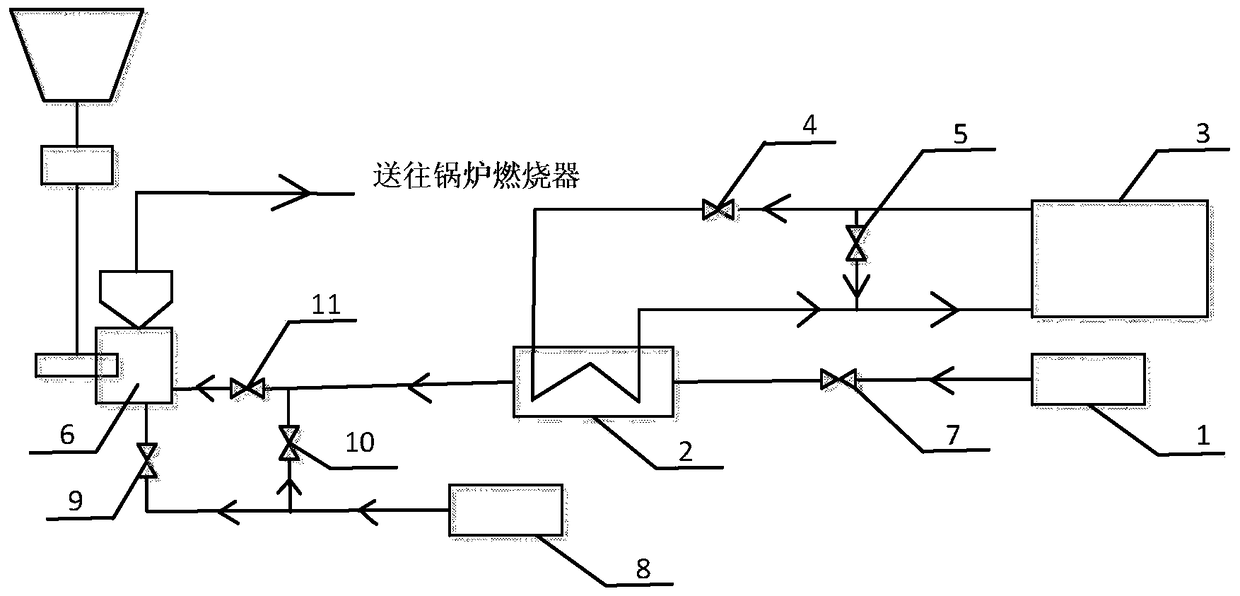

[0020] Such as figure 1 As shown, this embodiment provides a system for adjusting the air temperature at the inlet of the coal mill by using water supply, including an air preheater 1, a heat exchanger 2, and an economizer 3, wherein the heat exchanger 1 is a surface heat exchange The economizer adopts countercurrent heat exchange. The feedwater inlet of the economizer 3 is respectively connected with the inlet and outlet of the inner pipe of the heat exchanger 2 through two pipelines. The first feedwater regulating valve 4 and the The second feed water adjustment valve 5, the feed water of the economizer 3 enters the economizer after passing through the inner pipe of the heat exchanger 2, the first feed water adjustment valve 4 and the second feed water adjustment valve 5 are used to adjust the feed water entering the heat exchanger 2 water volume. The outlet of the air preheater 1 is connected to the inlet of the coal mill 6 through the heat exchanger 2, wherein the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com