Liquid crystal display panel and manufacturing method thereof

A technology of liquid crystal display panels and manufacturing methods, applied in nonlinear optics, instruments, optics, etc., can solve problems such as inability to fundamentally eliminate air bubbles, high production costs, and lower product yield, so as to reduce the risk of color resistance air bubbles and improve The flatness of the film surface and the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

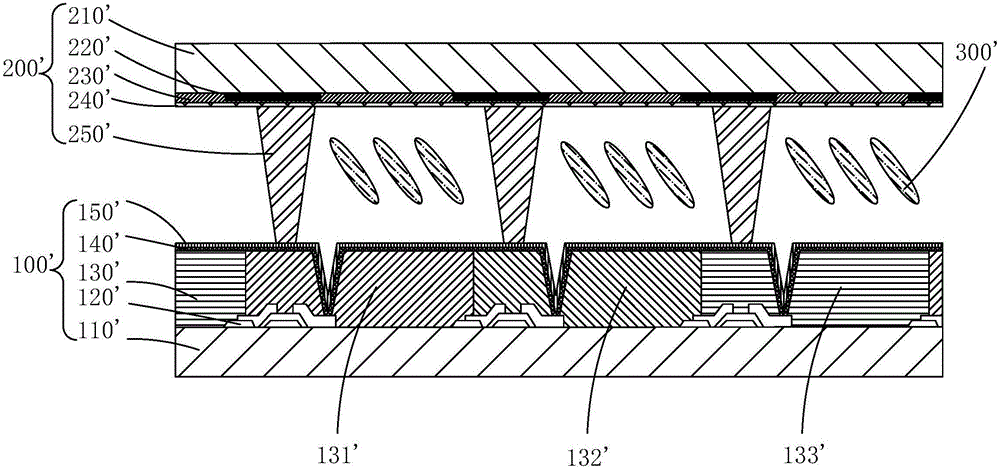

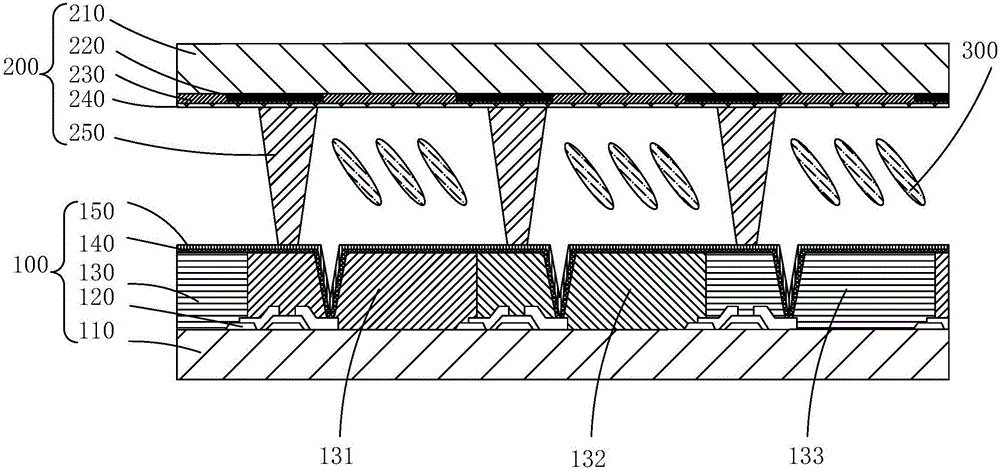

[0042] see Figure 2 to Figure 3 , the present invention provides a liquid crystal display panel: comprising a lower substrate 100 and an upper substrate 200 disposed opposite to each other, and a liquid crystal layer 300 sandwiched between the lower substrate 100 and the upper substrate 200 .

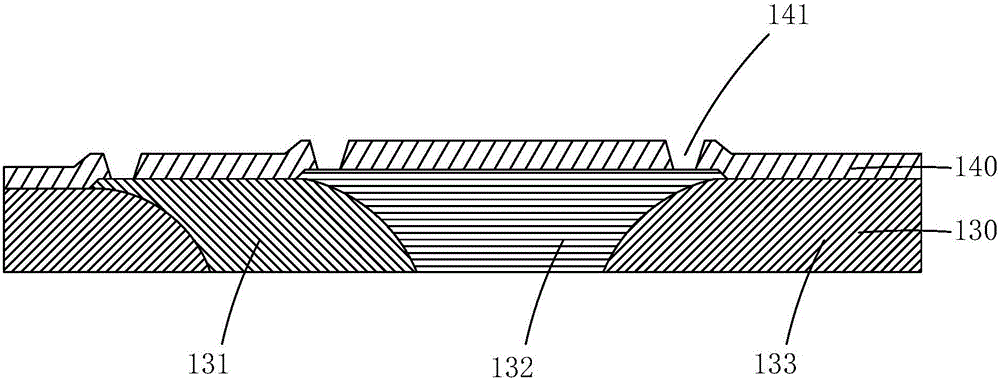

[0043]The liquid crystal display panel of the present invention is a COA liquid crystal display panel, that is, the color filter layer and the TFT array are arranged on the same side. Specifically, the lower substrate 100 includes: a first base substrate 110, a TFT array layer 120 disposed on the first base substrate 110; a color filter layer 130 disposed on the first substrate 110 and the TFT array layer 120 ; the passivation layer 140 disposed on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com