Integrated solution method for full-automatic harness processing device

A solution and technology of processing equipment, which is applied in the integrated solution field of automatic wire harness processing equipment, can solve the problems of human resources and waste of wire materials, etc., and achieve the effects of reducing production costs, realizing full automation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

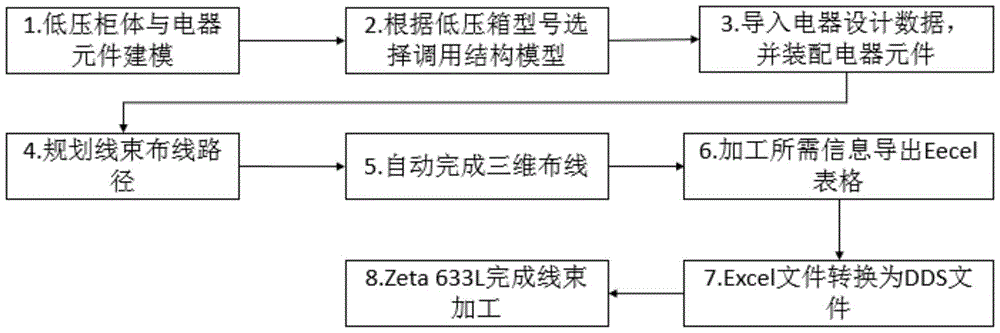

Method used

Image

Examples

Embodiment 1

[0027] 1. Modeling of low-voltage compartment cabinet and electrical components

[0028] The standard low-voltage compartment cabinet and electrical components can be modeled in 3D software and stored in EPLAN software for direct calling during electrical design. For non-standard ones, according to requirements, the size of the cabinet and its electrical components can be mechanically designed using 3D design software. The three-dimensional design software is Solidworks, proe, MAYA, caxa, sketchup, AUTOCAD and other similar design software. Non-standard low-voltage compartment cabinets and their electrical components can also be stored in EPLAN software for direct call during electrical design.

[0029] 2. Assembling electrical components

[0030] Use EPLAN software to complete the design of the electrical schematic diagram, and then import the electrical component list on the door panel with one click, or call the parts library data by entering the material number, and dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com