Solar cell output measurement tool and solar cell output measurement method

A solar cell and current measurement technology, applied in the parts, circuits, measuring electricity and other directions of electrical measuring instruments, can solve the problems of deviation in contact resistance, large deviation in thickness, and inconstant contact area between probes and finger electrodes. , to achieve the effect of reducing deviation and stabilizing output measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

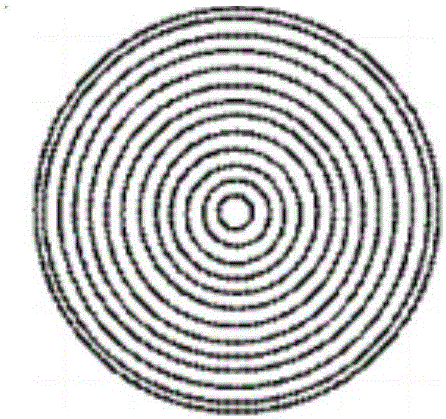

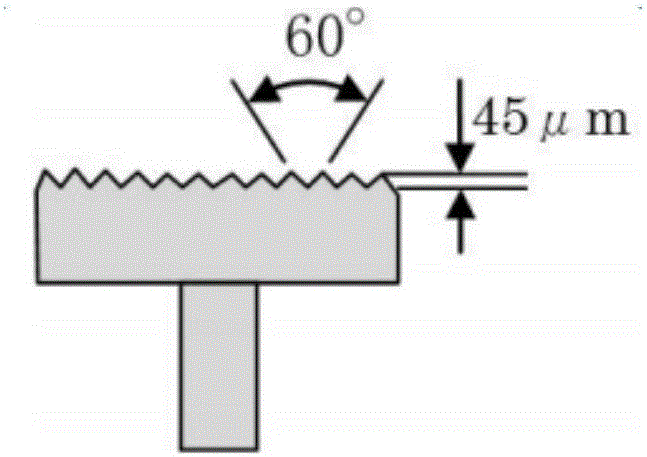

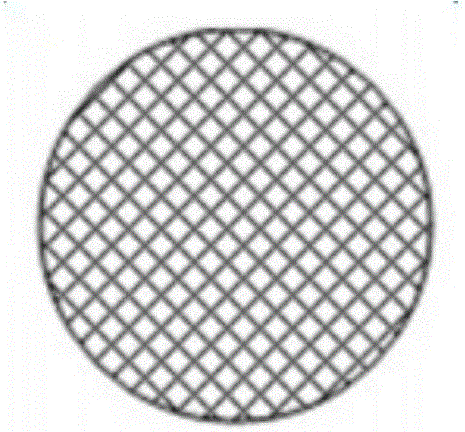

[0153] On the contact surface of the probe with a round tip (diameter 1.5mm), by cutting, an angle of 60°, an average depth of 45μm, and an average interval between adjacent circles in the concentric circle (average interval) are formed concentrically. ) for a 60μm groove ( Figure 17A as well as Figure 17B ).

[0154] Such as Figure 18 As shown, the probes formed with the grooves were arranged in a staggered manner in the area of the cell 1 with a side length of 156, arranged in two rows, and fixed by embedding in a resin material (stent). The bases (sockets) of the probes arranged in this way were soldered to copper wires for each row and bundled to produce an output measurement jig for a solar battery cell.

[0155] The row on one side of the bundle is the current measurement terminal, and the row on the other side is the voltage measurement terminal. These terminals are used by connecting them to a solar simulator.

Embodiment 2

[0157] In Example 1, the average interval (average pitch) between adjacent circles in the concentric circles of the grooves of the probe 4 was changed to 120 μm, and in the same manner as in Example 1, an output measurement jig for a solar battery cell was produced. .

[0158] In addition, the average depth of the grooves became 95 μm.

Embodiment 3

[0160] In Example 1, the average interval (average pitch) of adjacent circles in the concentric circles of the grooves of the probe 4 was changed to 250 μm, and in the same manner as in Example 1, an output measurement jig for a solar battery cell was produced. .

[0161] In addition, the average depth of the grooves became 210 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com