Cement semi-final powder milling vertical milling and ball milling combination system

A vertical mill and grinding technology, which is applied in the field of cement grinding, can solve the problems of difficult control of the fineness of semi-finished materials and low efficiency of semi-final grinding, so as to improve the quality of cement products, improve the efficiency of grinding and ball milling, and facilitate the process The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

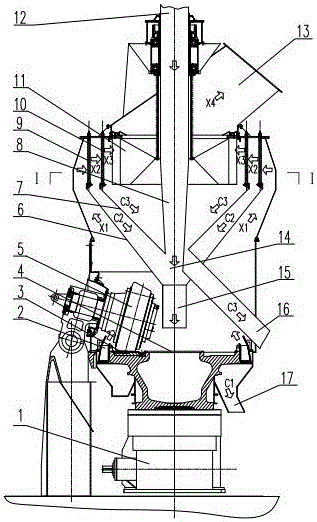

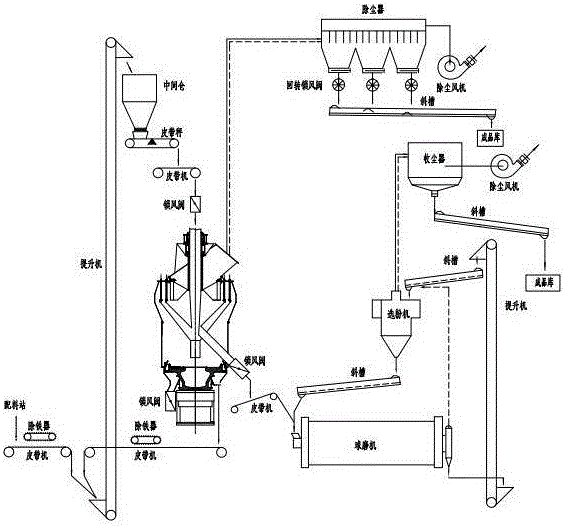

[0015] In order to overcome several shortcomings of the prior art, improve the grinding efficiency of the vertical mill and the powder selection efficiency of the powder classifier, and control the fineness of semi-finished materials at the same time, the present invention proposes a semi-final grinding vertical mill, which can be realized in Multiple sorting in the vertical mill is beneficial to improve the quality of cement.

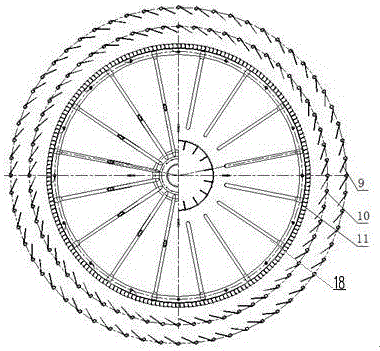

[0016] The technical scheme adopted in the present invention is: on the basis of the existing cement vertical mill, a coarse and fine powder separation device is further added. The semi-finishing vertical mill structure mainly includes: grinding rollers, grinding discs, grinding disc liners, blowing devices, reducers, material inlets, air outlets, semi-finished product outlets, slag discharge ports, and feeding cones. Feed cone 2, feed pipe, stationary vane 1, stationary vane 2, rotor. As the powder selection and separation device of the semi-finishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com