Pulsed power supply for electrostatic dust collection and generation method of pulsed power supply

A pulsed power supply and electrostatic precipitator technology, which is applied in the field of pulsed power supply for electrostatic precipitator and its generation, can solve the process bottleneck of high-voltage end coupling capacitor withstand voltage level and device volume, and cannot fully reflect the energy consumption advantages, technology and process of pulsed power supply Difficult to realize and other problems, to achieve the effect of easy process and technology, low cost, and improved dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

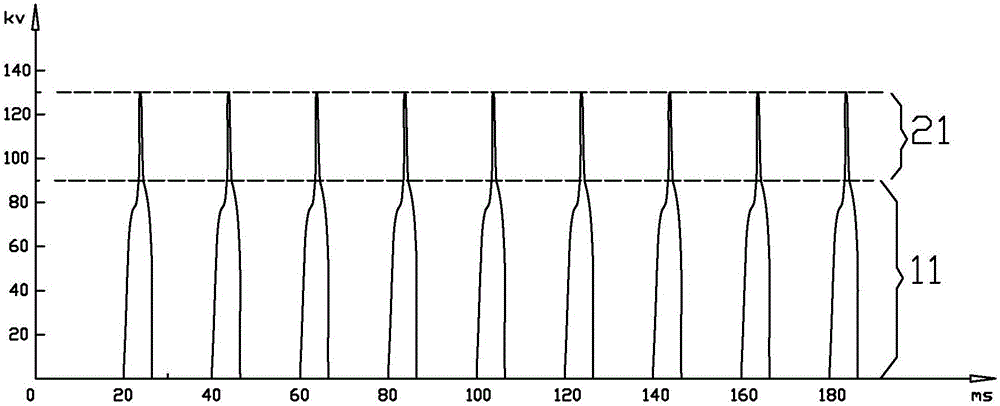

[0028] A method for generating a pulse power supply for electrostatic dust removal, specifically: generating an intermittent pulse power supply (such as image 3 11) and a narrow pulse power supply synchronized with it (such as image 3 21), and the pulse width of the intermittent pulse power supply (pulse width less than 10ms) is greater than the pulse width of the narrow pulse power supply (pulse width less than 100us), and then the synchronous narrow pulse power supply is superimposed in series on the peak value of the intermittent pulse power supply, like image 3 As shown, it is then applied between the collecting electrode and the discharging electrode of the electrostatic precipitator to drive the electrostatic precipitator to remove dust.

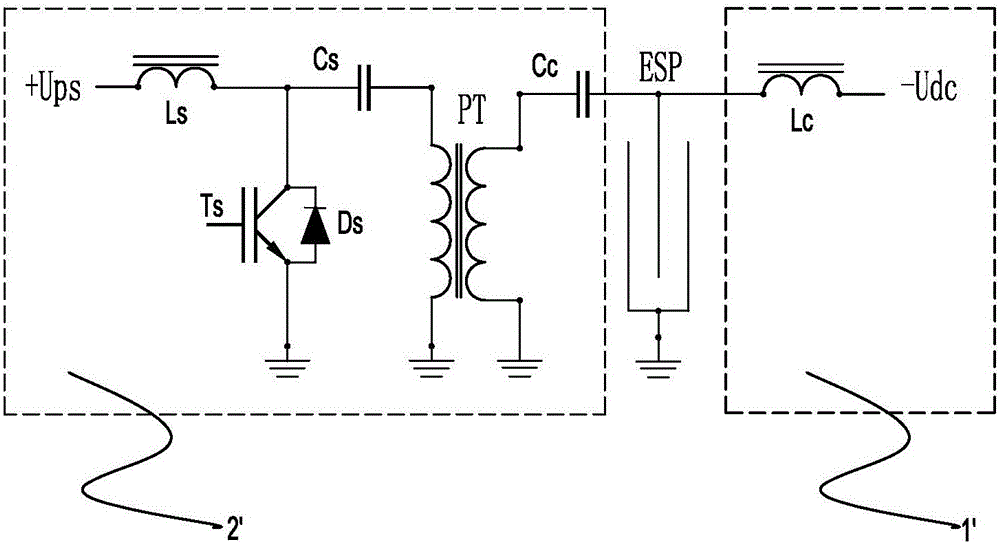

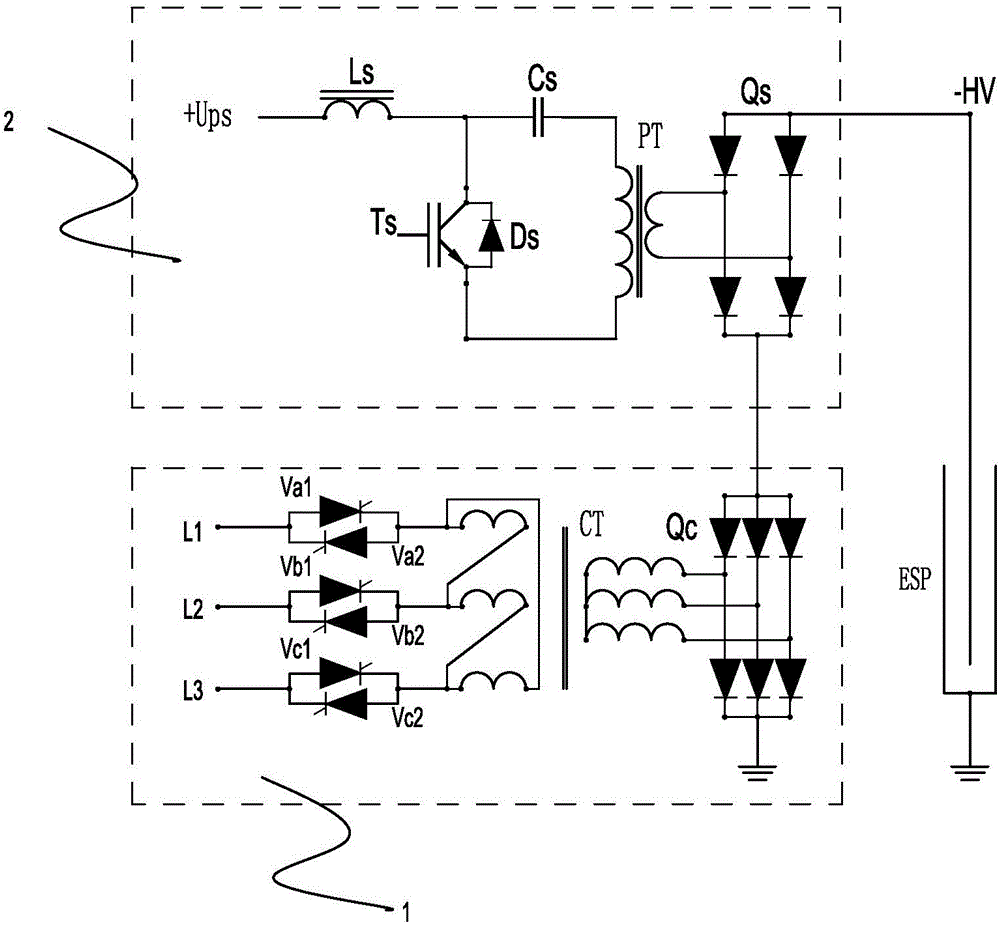

[0029] like figure 2As shown, a pulse power supply for electrostatic dust removal includes an inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com