Modular round cutter die-cutting machine

A circular knife mold and modular technology, which is applied in metal processing and other directions, can solve the problems of difficulty in guaranteeing the machining accuracy of the base, high cost, difficulty in transportation, transportation and lifting, etc. It is easy to guarantee the processing accuracy, easy to transport and hoist, The effect of easy serial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

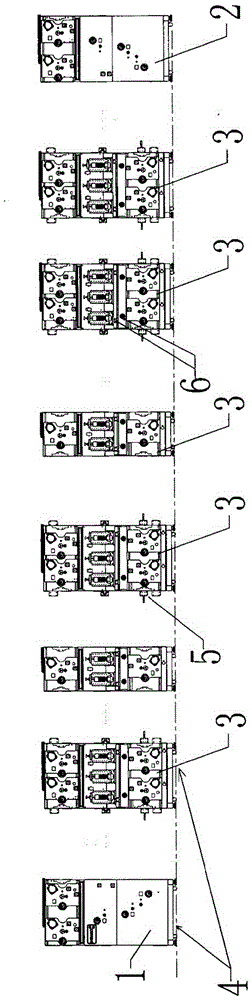

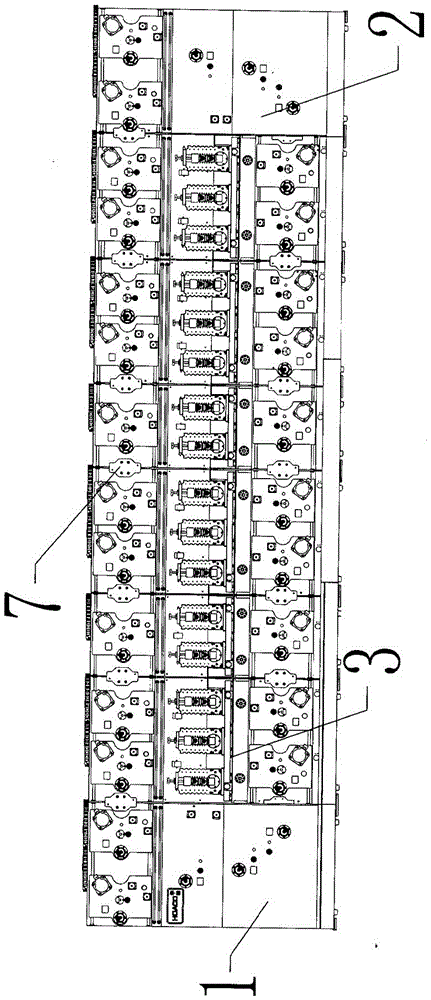

[0025] Example 1, such as figure 1 , figure 2 As shown, a modular circular knife die-cutting machine, the circular knife die-cutting machine adopts a modular structure, and the circular knife die-cutting machine is modularized according to the knife seat type station.

[0026] The circular knife die-cutting machine includes several independent module groups, and each module is detachably connected.

[0027] The circular knife die cutting machine includes a left module 1 , a right module 2 and several station modules 3 , and the station modules 3 are located between the left module 1 and the right module 2 .

[0028] Arbitrary combinations can be made between the various station modules 3 .

[0029] The number of tool seat type workstations contained in the workstation module 3 is at least 2 groups.

[0030] Preferably, the number of tool seat type workstations included in the workstation module 3 is 2 or 3 groups.

[0031] An appropriate number of station modules 3 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com