High speed train bogie power supply mode traction converter main circuit

A technology of traction converter and bogie, which is applied in electric traction, electric vehicles, AC power input to AC power output, etc. It can solve the problems of poor overall control performance, achieve accurate and stable voltage, and filter out the second harmonic wave, to ensure safe and reliable driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

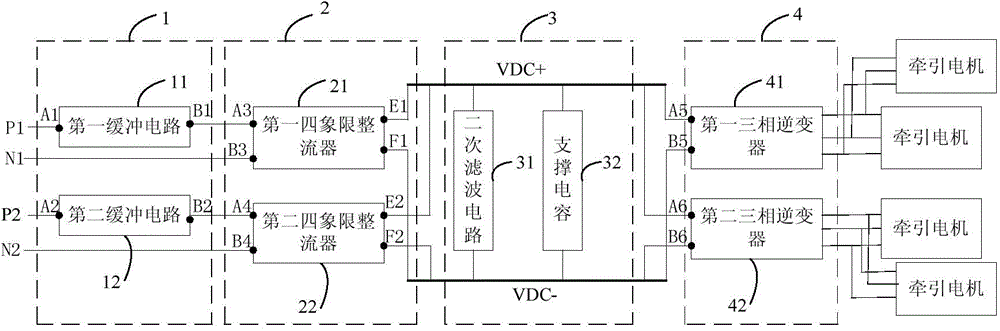

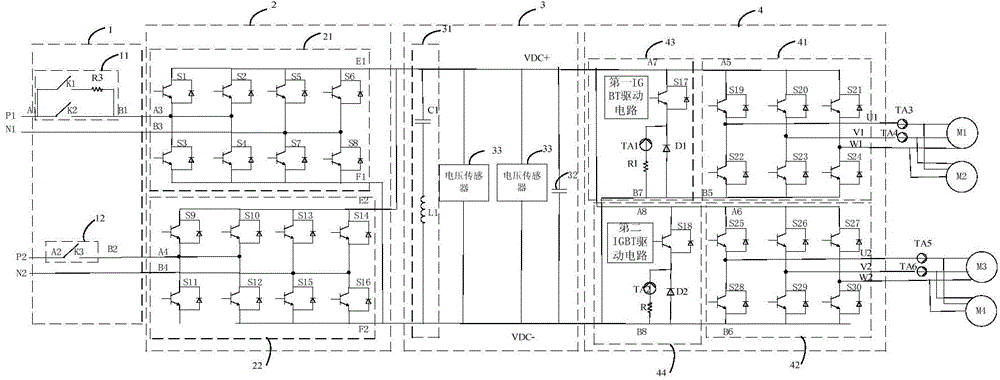

[0017] figure 1 It is a schematic diagram of the circuit composition of the first embodiment of the traction converter main circuit of the high-speed EMU bogie power supply mode of the present invention, as shown in figure 1 As shown, the main circuit includes:

[0018] A pre-charging circuit 1, a rectifying circuit 2, a bus voltage processing circuit 3 and an inverter circuit 4 connected in sequence;

[0019] The pre-charging circuit 1 is used to control the variation range of the input current when the traction converter is initially powered on, and the pre-charging circuit includes a first pre-charging circuit 11 and a second pre-charging circuit 12;

[0020] The rectifier circuit 2 includes a first four-quadrant rectifier 21 and a second four-quadrant rectifier 22 connected in parallel;

[0021] The first input terminal A3 of the first four-quadrant rectifier 21 is connected to the output terminal B1 of the first pre-charging circuit 11, and the second input terminal B3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com