Destacking machine with linkage type can moving and paper taking mechanism and destacking method

A linkage type, depalletizer technology, applied in the direction of object depalletization, transportation and packaging, etc., can solve the problems of unreasonable station connection, low work efficiency, low work efficiency of depalletizer, etc., and achieve simple mechanical structure and Control, simple movements, and orderly cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

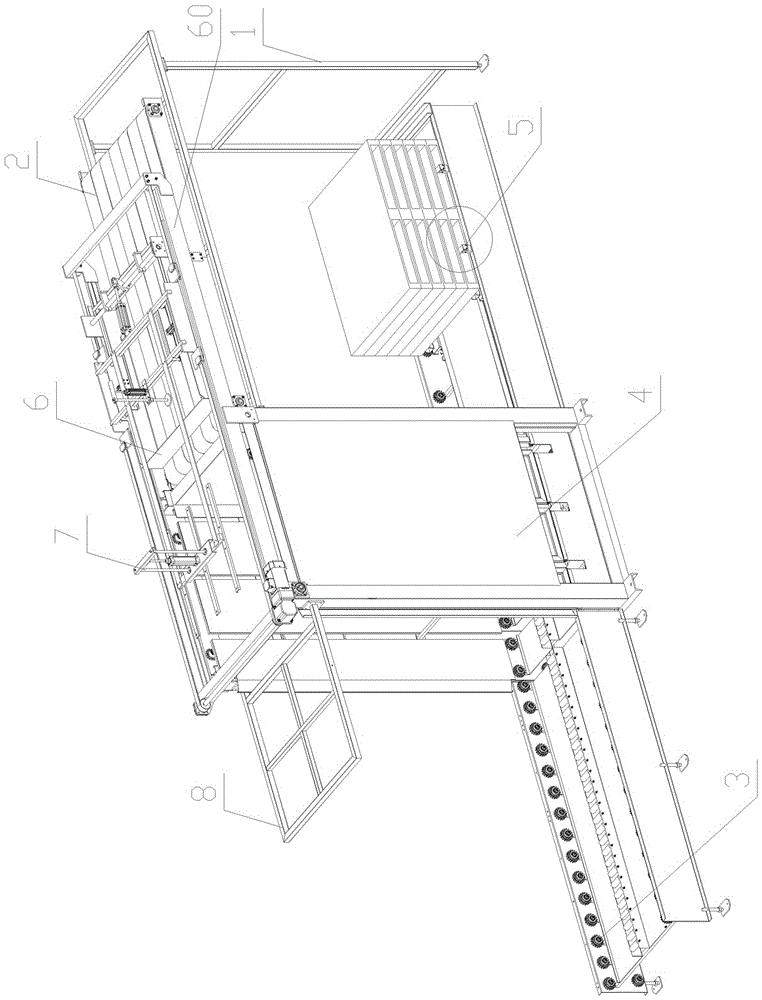

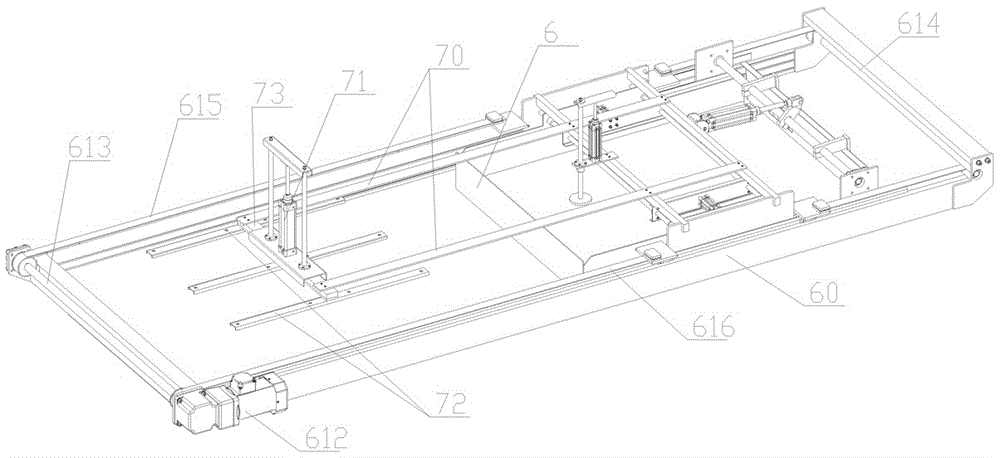

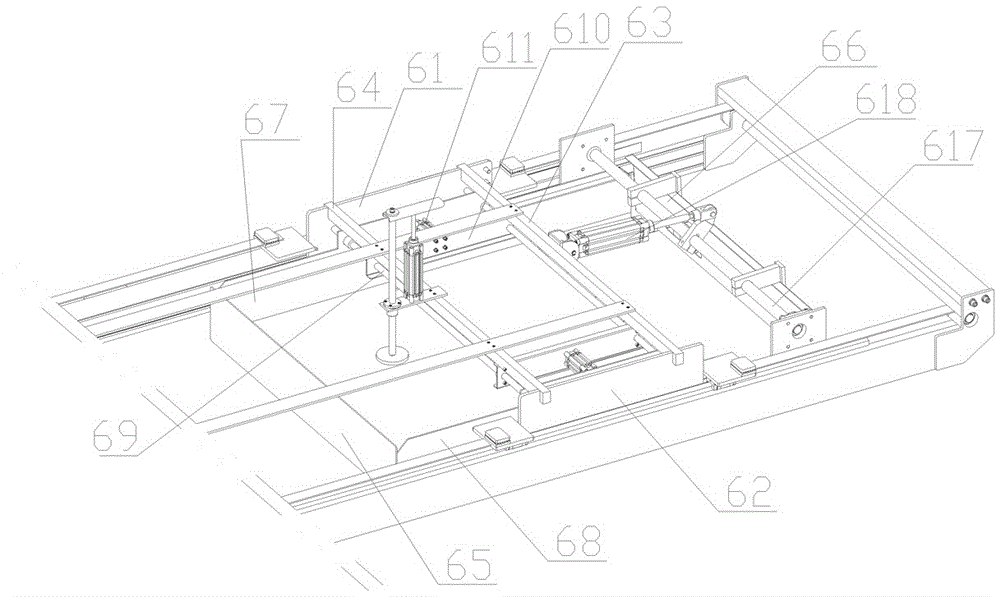

[0026] see figure 1 and figure 2 , a depalletizer with a linkage type can transfer and paper removal mechanism, the structure includes: a frame 1, a can stack conveying mechanism 3 located at the bottom of the frame 1, and a can stack conveying mechanism 3 arranged vertically above the can stack conveying mechanism 3 The can stack lifting mechanism 4, the can body conveying mechanism 2 and the paper storage rack 8 located on both sides of the upper part of the can stack lifting mechanism 4, the pallet palletizing mechanism 5 located at the output port of the can stack conveying mechanism 3, and the supporting management program The main control machine, a linkage type can transfer and paper taking mechanism is added between the can stack lifting mechanism 4 and the tank body conveying mechanism 2. 2 above the can transfer mechanism 6, the paper separator suction mechanism 7 above the can stack lifting mechanism 4 and the supporting horizontal reciprocating linear drive and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com