Wear-resistant glove for electric power

A technology of gloves and electricity, applied in gloves, applications, clothing, etc., can solve the problems of poor wear resistance, tear resistance and profit resistance, gloves can not be used continuously, waste of resources, etc., to improve the electrochemical corrosion resistance, The effect of improving process safety and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

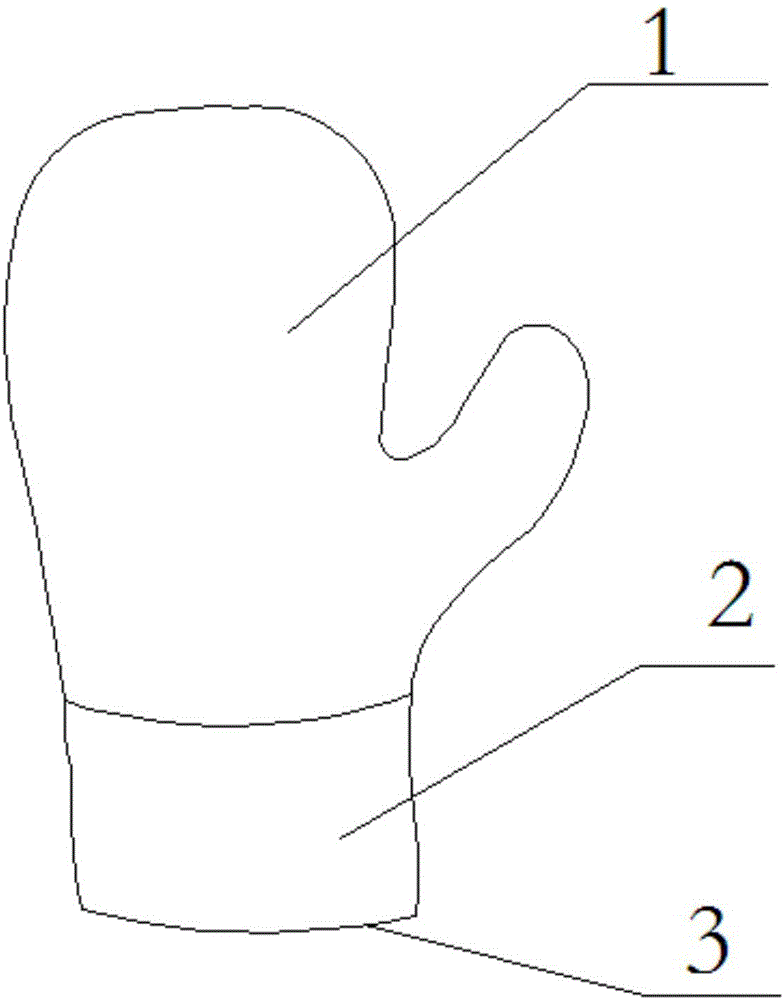

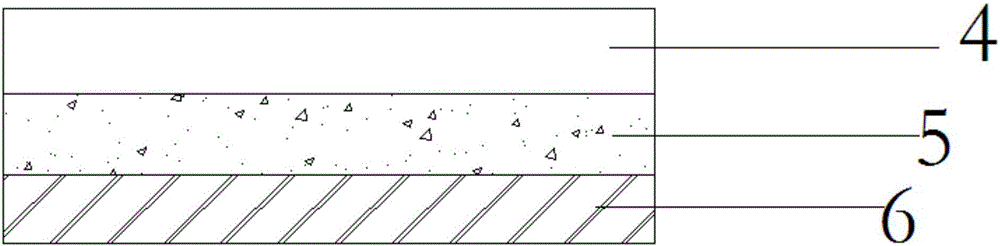

[0031] A wear-resistant glove for electric power, such as figure 1 , figure 2 As shown, it includes a working part 1, a skirt part 2 and an elastic adjustment part 3; the working part includes a wear-resistant layer 4, an insulating layer 5 and a fabric layer 6 that are attached to each other in sequence from the outside to the inside, and the wear-resistant layer 4 The thickness is 3 mm, the thickness of the insulating layer 5 is 1 mm, and the insulating layer 5 is a styrene-butadiene rubber insulating layer;

[0032] The raw material components of the wear-resistant layer are as follows, all in parts by weight:

[0033] 43 parts of styrene-butadiene rubber, 28 parts of neoprene rubber, 25 parts of fluoroether rubber, 2 parts of graphene, 14 parts of phenolic resin, 694 parts of silane coupling agent Si, 13 parts of semi-reinforced furnace black, 10 parts of calcined clay, 1 part of magnesium chloride Parts, 3 parts of magnesium powder, nano molybdenum disulfide (MoS 2 ) ...

Embodiment 2

[0041] A wear-resistant glove for electric power, such as figure 1 , figure 2As shown, it includes a working part 1, a skirt part 2 and an elastic adjustment part 3; the working part includes a wear-resistant layer 4, an insulating layer 5 and a fabric layer 6 that are attached to each other in sequence from the outside to the inside, and the wear-resistant layer 4 The thickness is 2 mm, the thickness of the insulating layer 5 is 1 mm, and the insulating layer 5 is a styrene-butadiene rubber insulating layer;

[0042] The raw material components of the wear-resistant layer are as follows, all in parts by weight:

[0043] 58 parts of styrene-butadiene rubber, 32 parts of neoprene rubber, 23 parts of fluoroether rubber, 5 parts of graphene, 5 parts of phenolic resin, 698 parts of silane coupling agent Si, 15 parts of semi-reinforced furnace black, 12 parts of calcined clay, 2 parts of magnesium chloride parts, magnesium powder 4 parts, nano molybdenum disulfide (MoS 2 ) 7 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com