Miniature two-dimensional scanning mirror

A two-dimensional scanning mirror and miniature technology, applied in the field of scanning mirrors, can solve the problems of difficulty in widespread use, high price, low yield, etc., and achieve the effects of being conducive to large-scale mass production, simple overall structure, and easy to miniaturize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

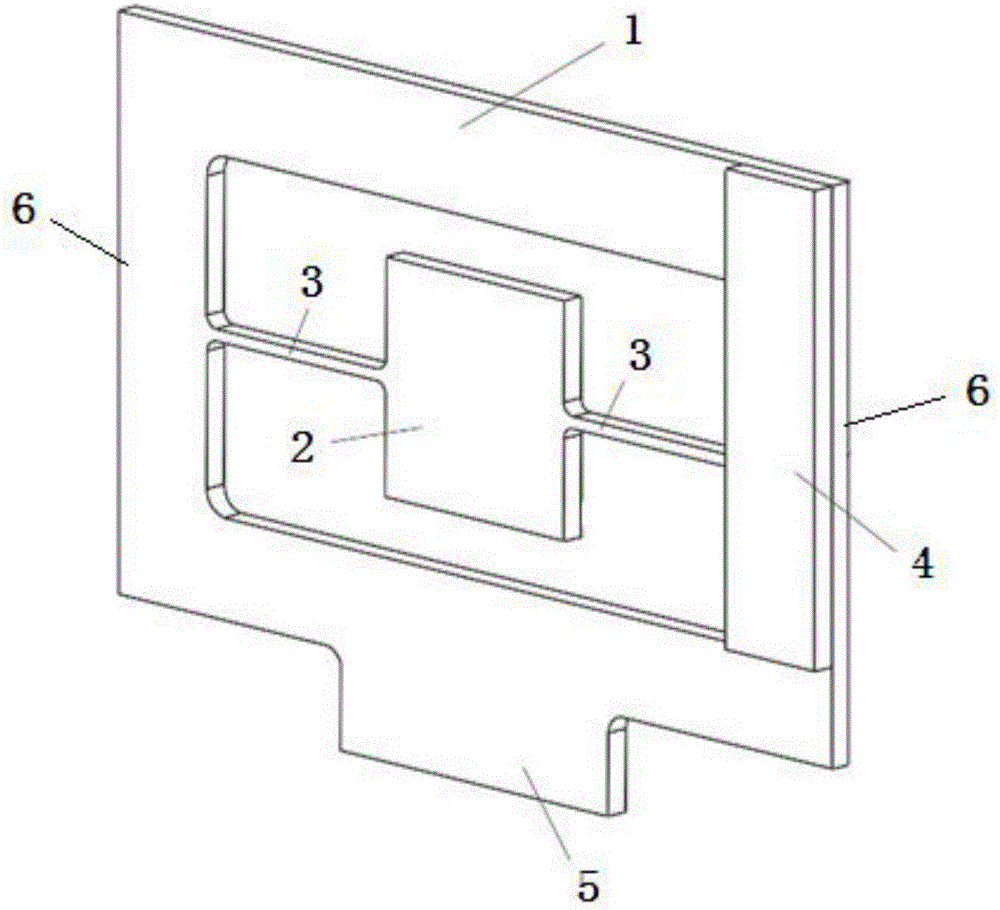

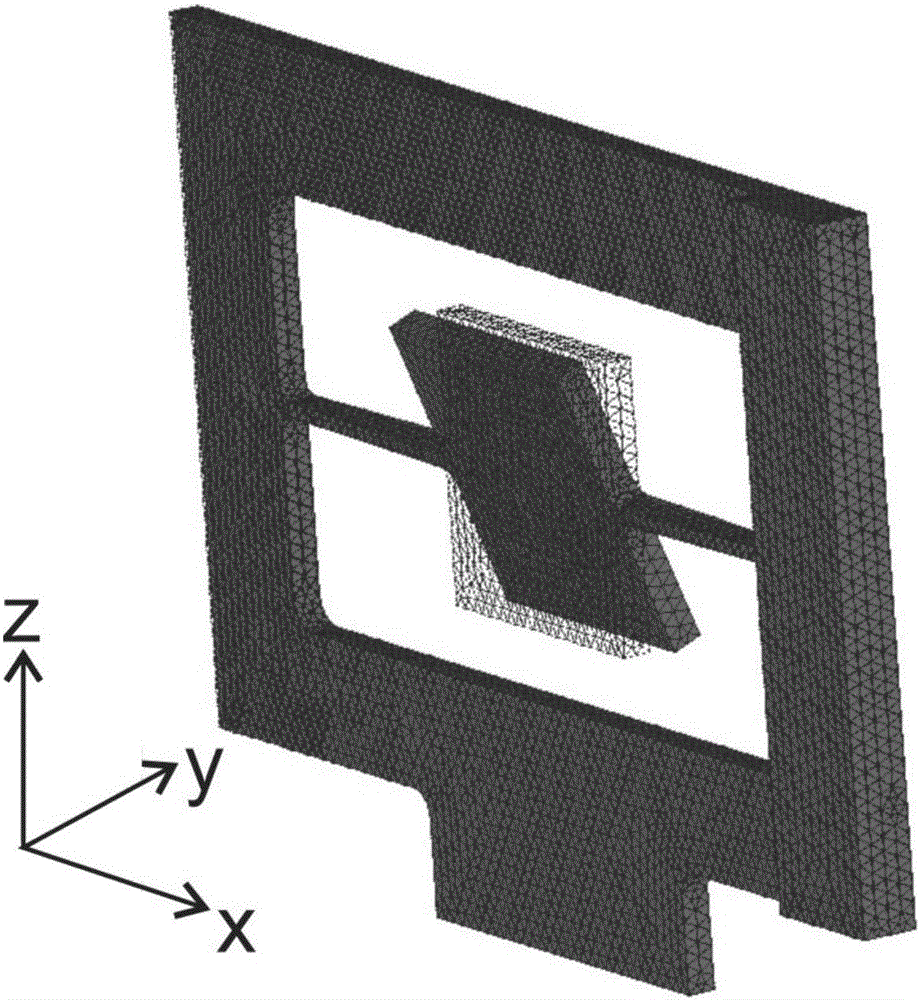

[0024] Such as figure 1 As shown, this case lists a miniature two-dimensional scanning mirror of an embodiment, which includes:

[0025] Bracket 1, which is surrounded by metal strips to form a frame, and has two side arms 6;

[0026] The reflector 2 is suspended in the frame by two symmetrically distributed elastic arms 3, one end of the elastic arm 3 is connected to the reflector 2, and the other end is connected to the side arm 6 of the bracket 1;

[0027] The piezoelectric sheet 4, which is arranged on the side arm 6 of the support 1, is used to generate an inverse piezoelectric effect under the action of an electric field, thereby driving the reflection sheet 2 to rotate. After the piezoelectric sheet 4 is energized, an inverse piezoelectric effect is generated, which drives the bracket 1 to generate bending vibration, thereby stimulating the twisting or bending of the elastic arm 3, and driving the reflective sheet 2 to deflect at a certain angle. When the vibration fr...

Embodiment 2

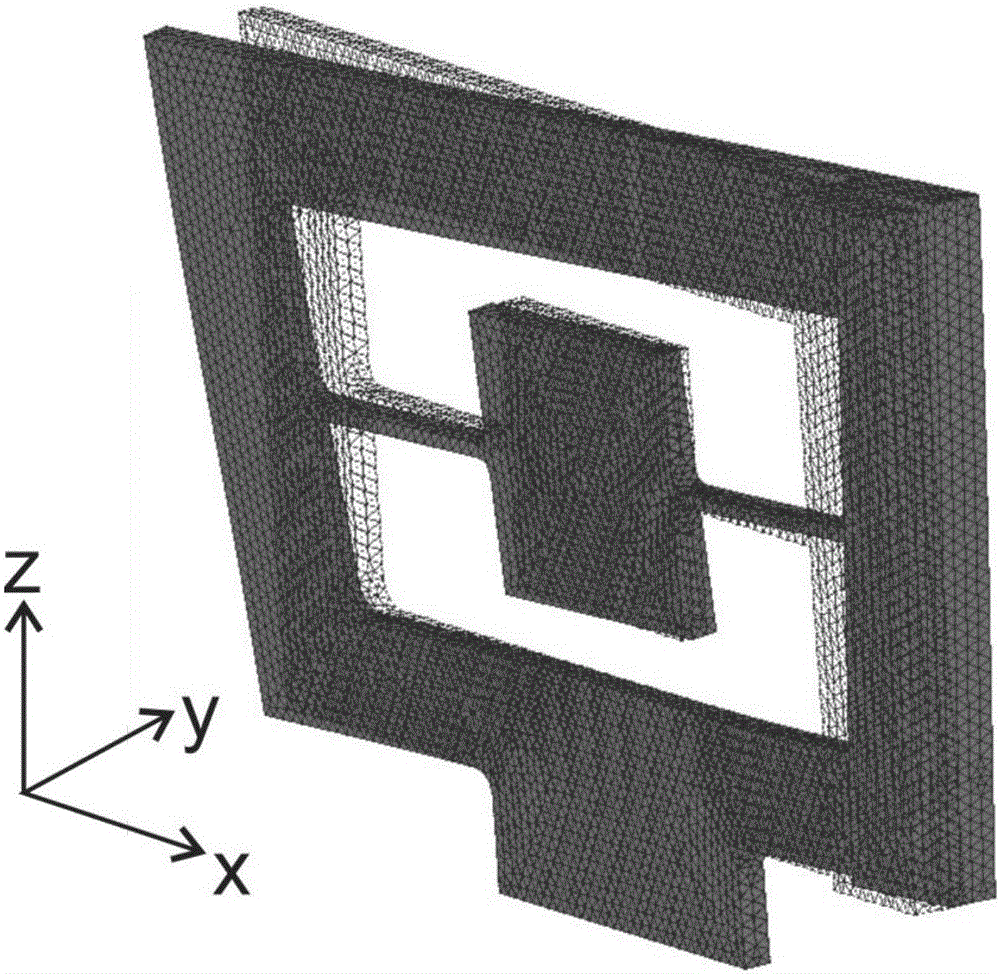

[0031] Such as Figure 4 As shown, on the basis of Embodiment 1, at least two piezoelectric sheets 4 are provided, and they are respectively located on the two side arms 6 of the support 1; four sheets can also be provided, that is, as Figure 4 In the piezoelectric sheet 4a, piezoelectric sheet 4b, piezoelectric sheet 4c and piezoelectric sheet 4d.

[0032] In this embodiment, when the number of piezoelectric sheets 4 is two, the two piezoelectric sheets 4 can be located on the same side of the plane where the support 1 is located (such as piezoelectric sheet 4a and piezoelectric sheet 4d, or piezoelectric sheet 4b and piezoelectric sheet 4c) or on both sides of the plane where the support 1 is located (such as piezoelectric sheet 4a and piezoelectric sheet 4c, or piezoelectric sheet 4b and piezoelectric sheet 4d). When the number of piezoelectric sheets 4 is two, there are three working modes: working mode 1: After applying the driving signal, the piezoelectric sheet is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com