Cooling and drying electrical cabinet convenient to move and position

A convenient moving and drying technology, applied in electrical components, substation/distribution device enclosures, substation/switch layout details, etc., can solve the problems of reduced service life of electrical components, influence of heat on internal electrical components, and difficulty in dissipating heat from electrical components. , to achieve the effect of fast operation, convenient movement and positioning, and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

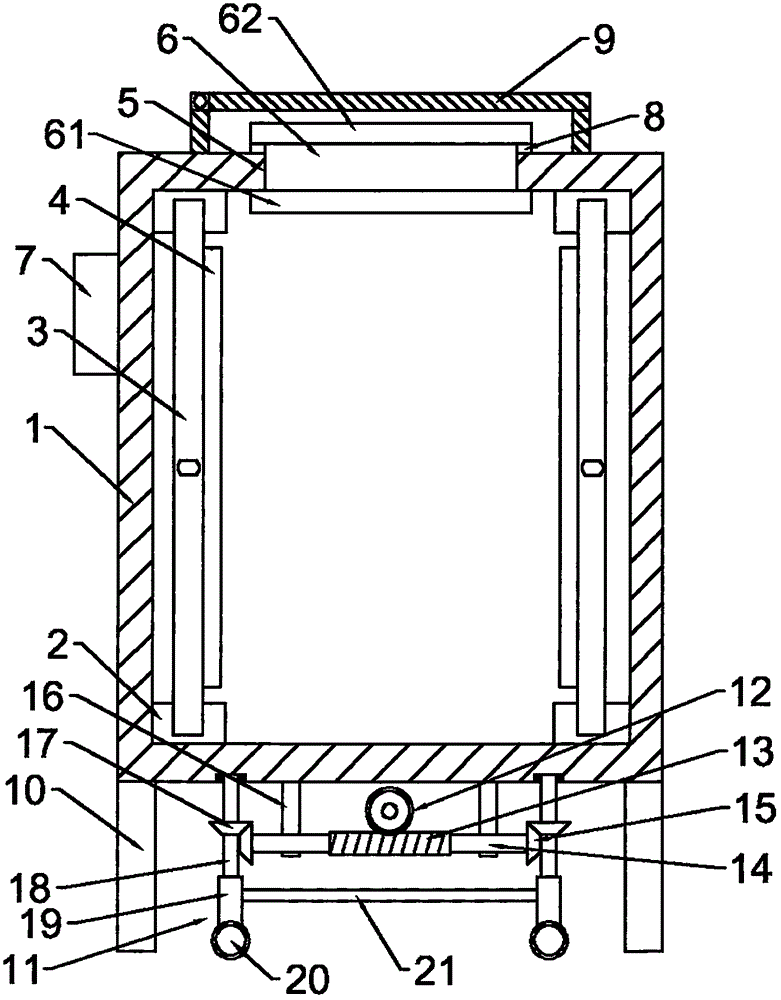

[0015] see figure 1 , a heat dissipation and drying electric cabinet that is convenient to move and locate, including a cabinet body 1, the left and right sides of the bottom and the left and right sides of the top of the cabinet body 1 are respectively provided with chute 2 along the front and rear directions, and the left and right sides of the cabinet body 1 , between the right side chute are respectively provided with a support plate 3, and the top and bottom ends of the support plate 3 are respectively slidably installed in the top and bottom chute 2 of the corresponding side, and the two support plates 3 are respectively provided with remote Infrared heating plate 4, the top of the cabinet body 1 is provided with an installation port 5, and a semiconductor refrigeration chip 6 is arranged in the installation port 5. The cold end 61 of the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com