Sensorless starting method for automobile air conditioner

A technology of automotive air conditioners and sensors, applied in the direction of starting devices, etc., can solve the problems of unguaranteed, large starting torque, low resolution, etc., and achieve the effects of avoiding alignment failure, reducing collision and noise, reducing alignment current and alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

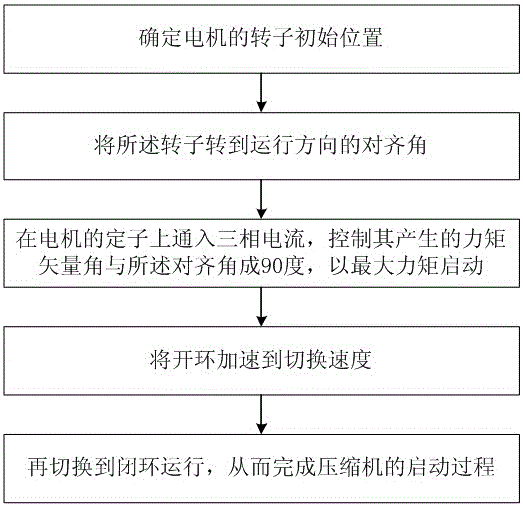

[0029] Such as figure 1 The shown a kind of automobile air-conditioning sensorless starting method of the present invention comprises the following steps:

[0030] (1) Determine the initial position of the rotor of the motor;

[0031] (2) Turn the rotor to the alignment angle of the running direction;

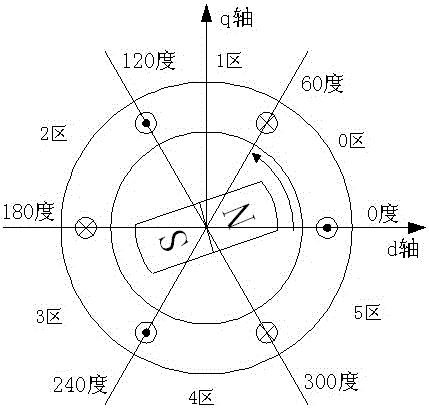

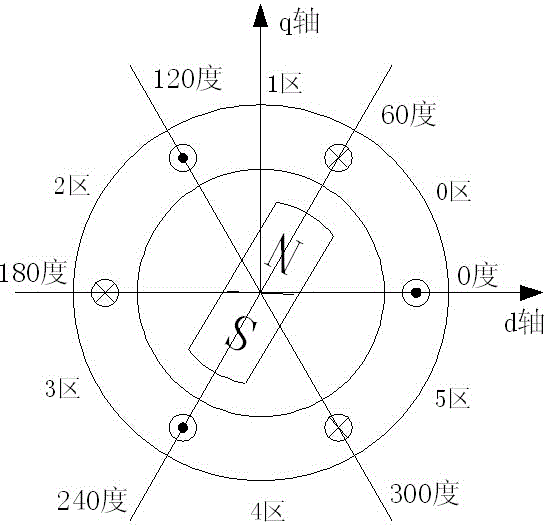

[0032] (3) Pass three-phase current on the stator of the motor, control the torque vector angle generated by it to be 90 degrees to the alignment angle, and start with the maximum torque; specifically use SVPWM technology, apply two adjacent The resulting vector of the voltage vector has its vector angle at 90 degrees to the stated alignment angle and is activated with maximum torque.

[0033] (4) Immediately after starting, it enters the open-loop stage, and the rotor continues to increase speed with the set acceleration curve until the speed reaches the set switching speed.

[0034] (5) When the switching speed is reached, the rotor position information has converged and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com