Immobilized microorganism carrier, and contact oxidation combination system employing same

A microbial immobilization and carrier technology, which is applied in the direction of immobilized enzymes, biochemical equipment and methods on/in organic carriers, can solve problems that have not been studied, and achieve improved wear resistance and excellent performance. The effect of purification treatment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

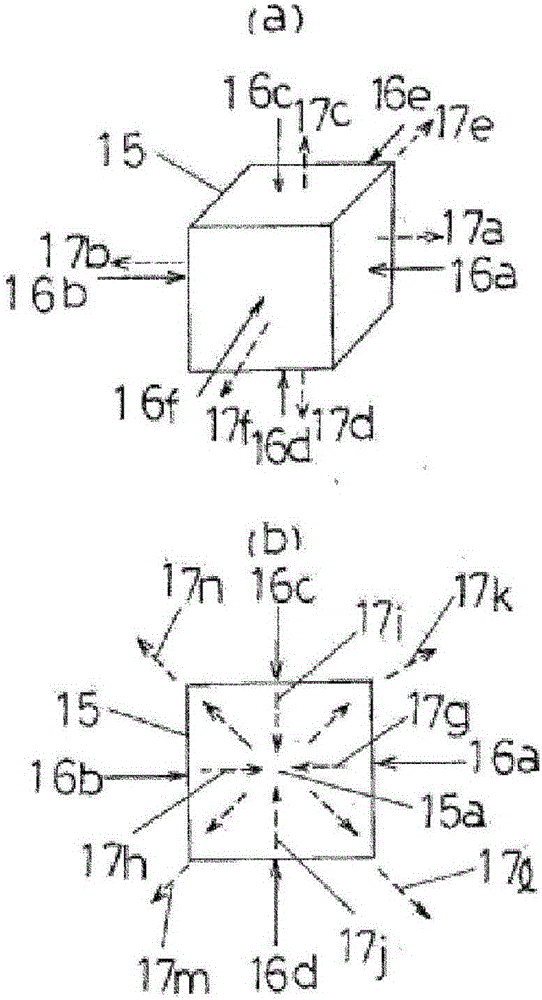

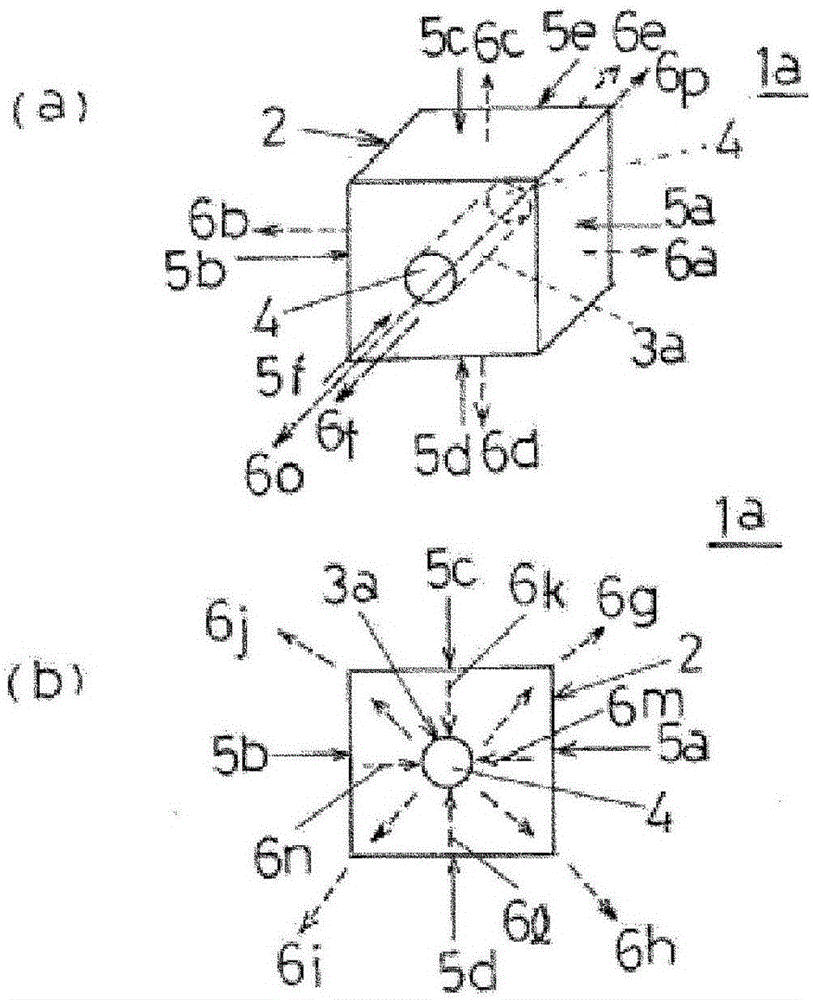

[0078] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 2 is a diagram showing the microorganism immobilization carrier of the present invention.

[0079] figure 2 The microbial immobilization carrier composed of porous foam of the present invention shown in the figure is a carrier for carrying aerobic microorganisms in the activated sludge in the aeration tank, and can be obtained by adjusting the water swelling properties known in the technical field. Manufactured by processing synthetic resins such as polyurethane foam, inorganic materials such as ceramics and silica gel, and sponges.

[0080] In this embodiment, the foam 2 made of a synthetic sponge material such as polyurethane sponge is processed to make microorganism immobilization carriers 1a, 1b ( figure 2 (a), (b)). In addition, microorganism immobilization carriers 1c, 1d, and 1e ( figure 2 (c), (d), (e)).

[0081] The shape of the microorganism immo...

example 1

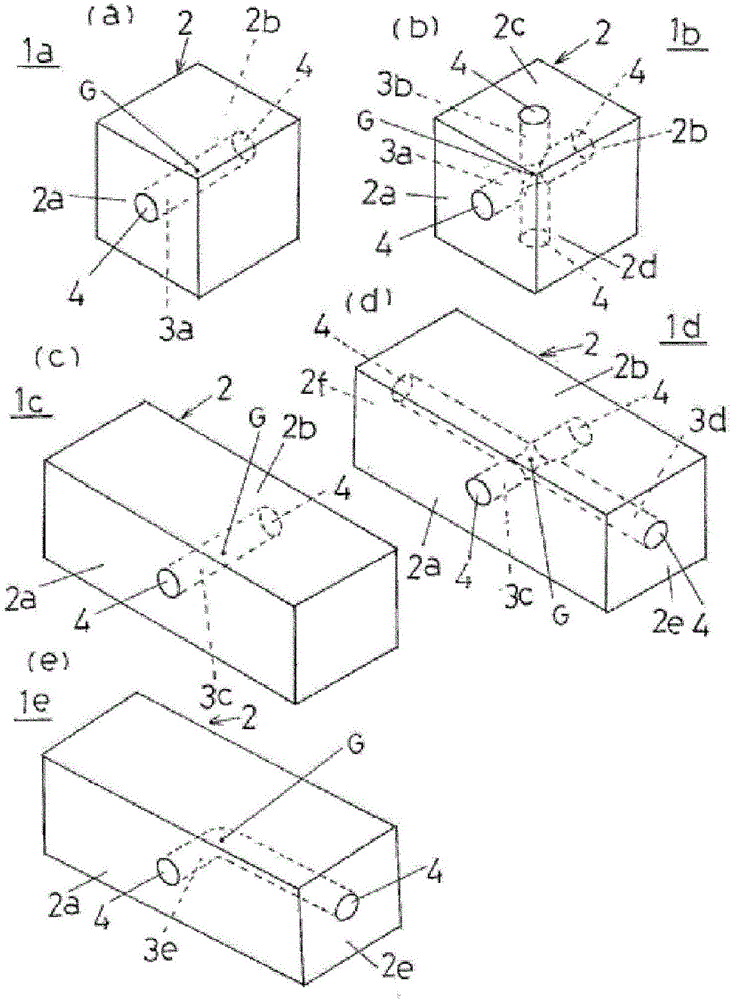

[0166] use figure 1 Microorganism immobilization carrier composed of conventional porous foam (resin sponge) explained

[0167] Dimensions: 10mm×10mm×10mm cube shape

[0168] Cavity: no

[0169] Ring-shaped film of the inner peripheral wall of the cell forming the porous structure of the foam: no test body 3 (comparative example 2)

[0170] The microorganism-immobilized carrier of the structure described in Embodiment 1

[0171] Dimensions: 10mm×10mm×10mm cube shape

[0172] The size of the cavity: a cylindrical cavity with a diameter of 7mm

[0173] Such as Figure 7 As shown in (a), the ring-shaped membrane structure is formed on the inner peripheral wall of the cell forming the porous structure of the foam

[0174] About each test body, the dry weight before implementation of an abrasion test and after implementation of an abrasion test was measured, respectively.

[0175] express the result in Figure 11 in the graph of . In test bodies 2 and 3 (comparative exampl...

Embodiment approach 2

[0185] Figure 12 A schematic configuration of an example of a composite water purification treatment system of a fixed bed method and a fluidized bed method in which a fixed bed method and a fluidized bed method are combined in the water purification treatment system of the present invention, that is, an example of a combined contact oxidation system is described. picture.

[0186] In the purified treated water from the upstream side ( Figure 12 middle, left side) to the downstream side ( Figure 12 In a water tank 1 for purification treatment flowing in the middle, right side), a fluidized bed area 22 and a fixed bed area 23 are adjacently provided, and a wire mesh 24 is arranged at the boundary between the fluidized bed area 22 and the fixed bed area 23.

[0187] The wire mesh 24 enables the flow of treated water between the fluidized bed region 22 and the fixed bed region 23 , while preventing the fluidized bed contact material 29 flowing in the fluidized bed region 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com