Fine pounding method of rice grains

A technology for rice grains and brown rice, which is applied to the field of fine pounding of rice grains, can solve the problems of excessive grinding of the side of the rice grains, reduce the moisture content of the rice grains, and deteriorate the taste of the rice grains, and achieve the effects of reducing energy costs, reducing water consumption, and avoiding the exposure of endosperm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

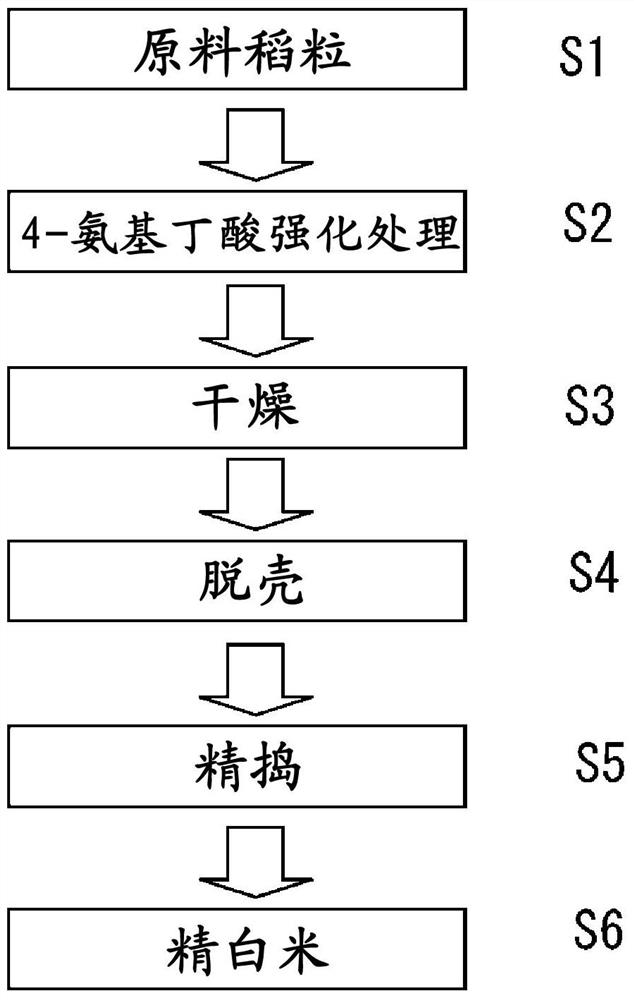

[0061]Next, in order to confirm the effect of the rice milling machine according to the embodiment of the present invention, two types of rice milling machines (Hinoko (variety name) produced in Hiroshima Prefecture in 2012 and Yumebijin (name of variety) produced in Hokkaido in 2012 were used. Rice grains were tested. The initial value of 4-aminobutyric acid in 100 g of Hinoko produced in Hiroshima Prefecture as the test rice was 3.5 mg (dry basis, the same below). In addition, the initial 4-aminobutyric acid value of Yumebijin from Hokkaido, which is the test rice, was 3.1 mg per 100 g. Thus, through figure 1 The procedure of S1 to S4 obtains 4-aminobutyric acid fortified brown rice.

[0062] With respect to the 4-aminobutyric acid-enhanced brown rice, an experiment was conducted to verify whether there is a difference in the quality of polished rice between a rice polisher according to an embodiment of the present invention and a conventional rice polisher.

[0063] Tabl...

Embodiment 2

[0070] Then, the experiment when the starting material was brown rice was performed similarly to the above. The first 4-aminobutyric acid value of Hinoko produced in Hiroshima prefecture in 2003 as the brown rice tested was 3.3 mg per 100 g. Thus, through Figure 4 The procedure of S11 to S13 obtains 4-aminobutyric acid fortified brown rice.

[0071] With regard to the 4-aminobutyric acid-enhanced brown rice, an experiment was conducted to see whether there is a difference in the quality of polished rice between the rice polisher according to the embodiment of the present invention and the conventional rice polisher.

[0072] Table 2 compares polished rice (hereinafter referred to as "new polished rice") polished with a rice polisher according to an embodiment of the present invention and a commercially available friction rice polisher (MIRUMOA (Model: HRP25A) manufactured by Satake Corporation). The value of 4-aminobutyric acid and other functional components contained in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com