Self-propelled type boot washing device for coal mines and manufacturing method of self-propelled type boot washing device

A production method and self-propelled technology, which is applied in the field of coal mine equipment, can solve the problems of high labor intensity, labor, and physical and mental health injuries of coal miners, so as to reduce labor intensity and workload, make efficient and practical, and shorten the time for washing boots Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

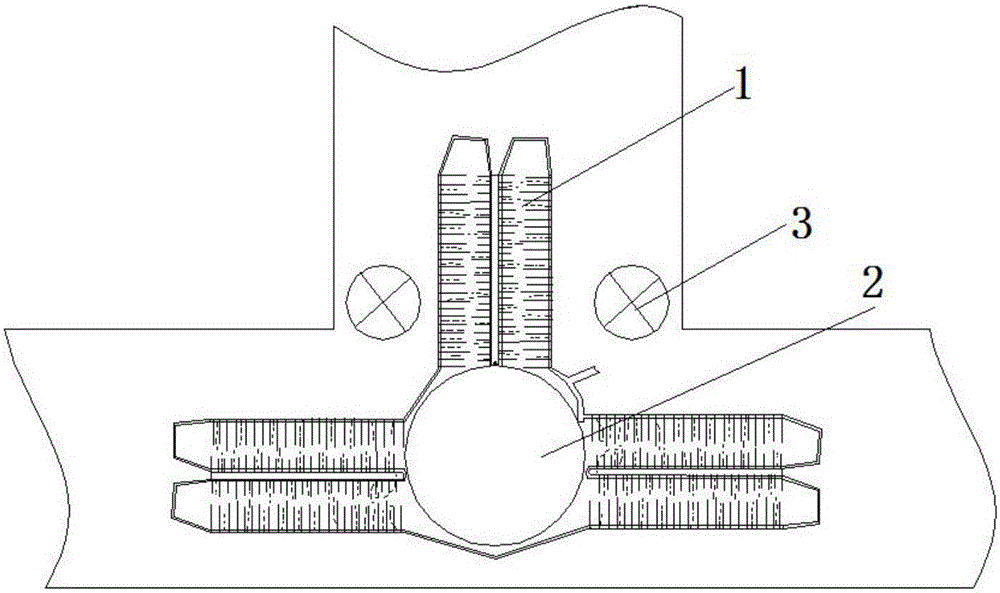

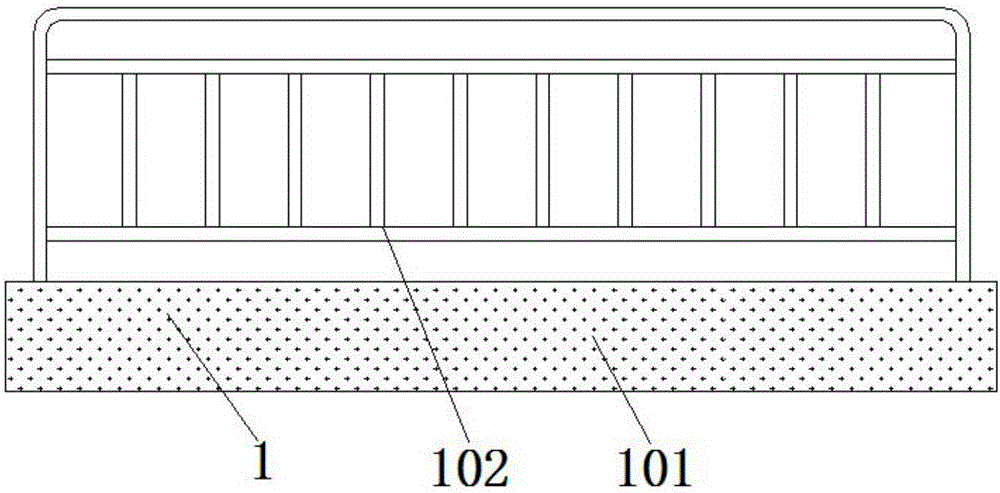

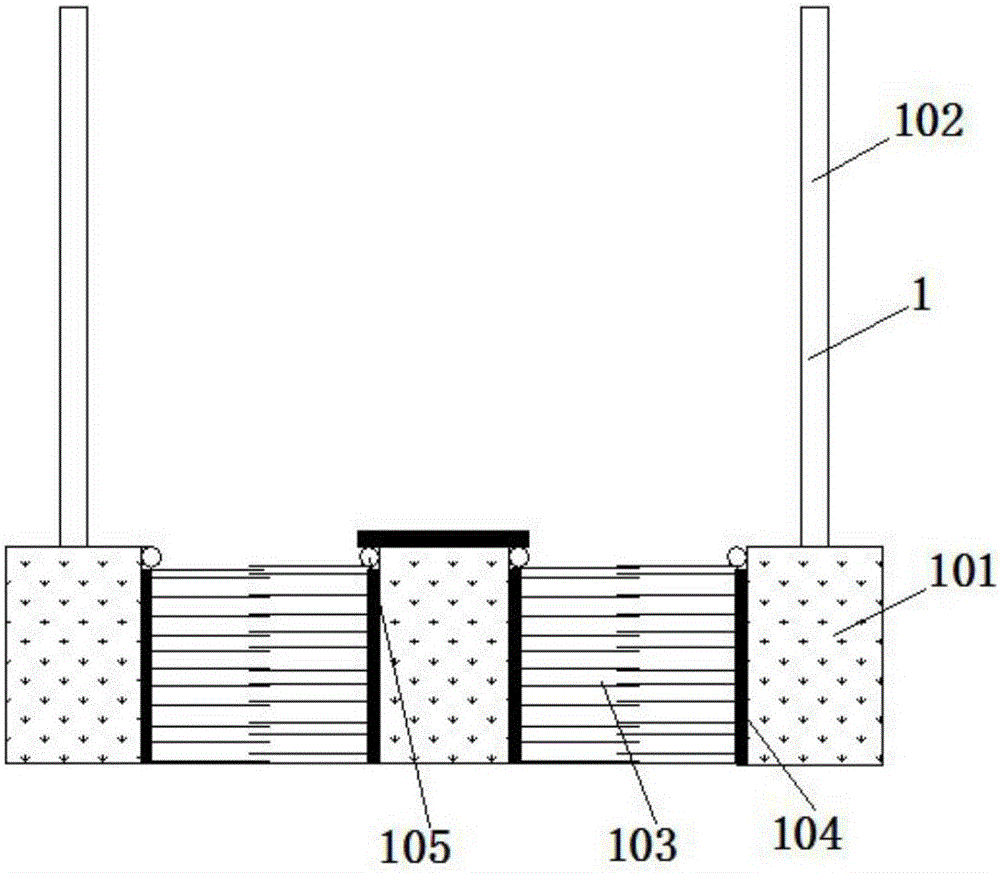

[0032] Such as Figure 1 to Figure 4 As shown, a self-propelled boot washing device for coal mines includes a boot washing device 1, a pool 2 and a one-way passing fence 3; the number of boot washing devices 1 is three, and the boot washing device 1 is centered on the pool 2 Installed at 90 degrees, the one-way passing fence 3 is located between the boot washing device 1; the boot washing device 1 includes a concrete pier 101, a railing 102, an iron grate 103, a rubber plate 104, a water pipe 105 and a brush 106; The cross-section of the concrete piers 101 described above is in the shape of a "mountain". The railing 102 is installed on the upper surface of the concrete piers 101, the iron grate 103 is installed at the bottom of the gap between the concrete piers 101, and the rubber plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com