Fuel gas type universal rapid aluminum bar heating system for long bars and short bars

A heating system and general-purpose technology, which is applied in the field of aluminum bar heating, can solve the problems of inability to realize universal heating or peeling of long and short bars, inability to provide high-temperature short aluminum bars in general, and incapable of peeling by hot peeling machines, so as to achieve a high production yield. , the effect of high degree of mechanization and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

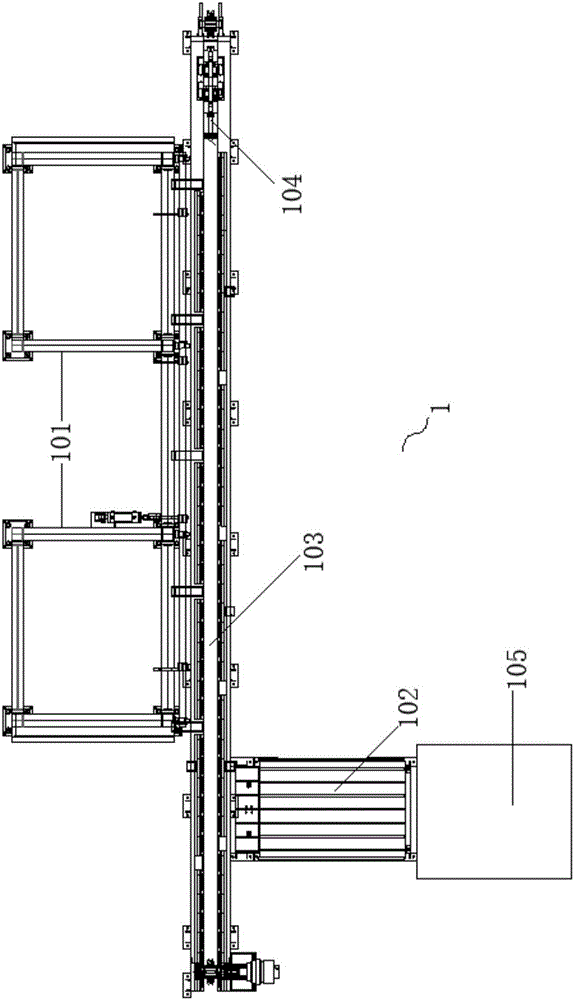

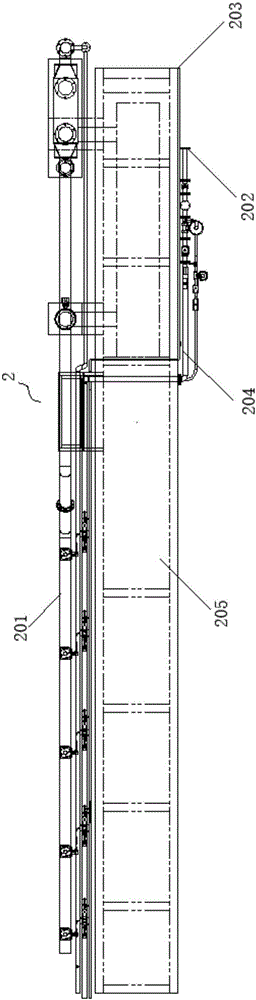

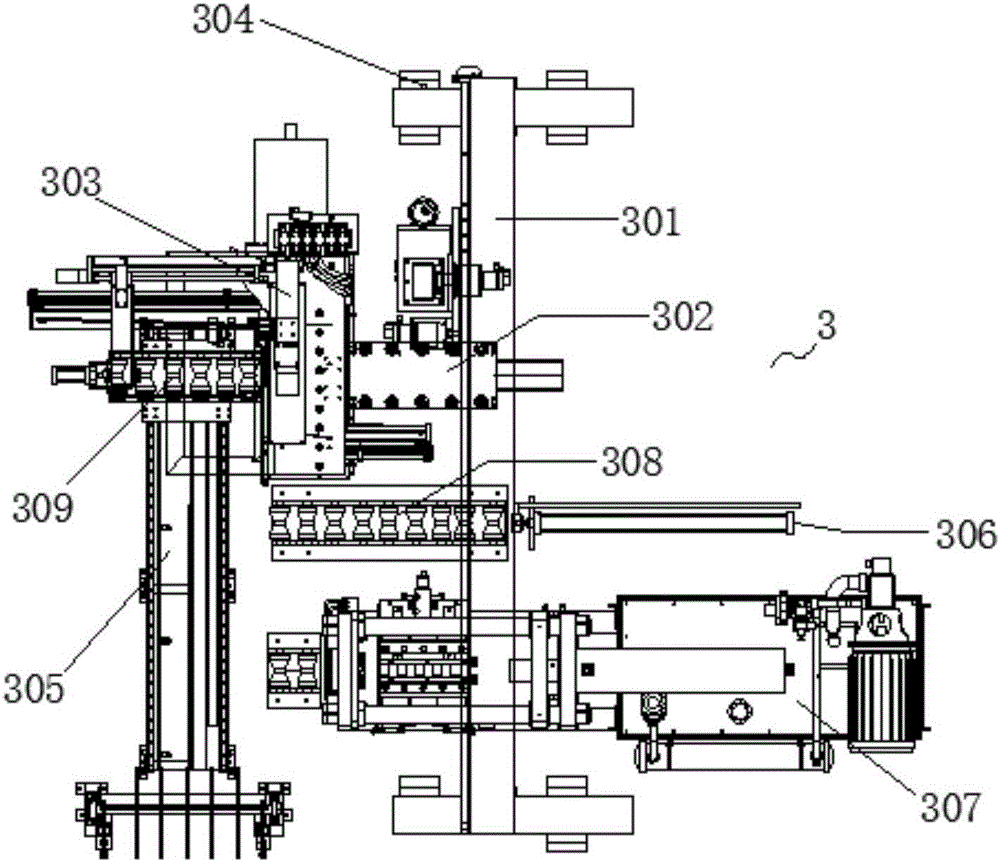

[0028] Such as Figure 4 As shown, the gas-fired long and short rod general-purpose fast aluminum rod heating system of the present invention includes a feeding unit 1, a heating unit 2 and a peeling and shearing unit 3, and the feeding unit 1, the heating unit 2 and the peeling and shearing unit 3 are transported The roller tables are connected sequentially. The conveying roller table of the present invention comprises a series connection feeding conveying roller table 103, a heating conveying roller table 205 and a power aluminum bar conveying roller table 302, the feeding conveying roller table 103 is arranged in the feeding unit 1, and the heating conveying roller table 205 is arranged in the heating unit 2, the power aluminum rod conveying roller table 302 is set in the peeling and shearing unit 3.

[0029] Such as figure 1 As shown, the feeding unit 1 includes a feeding conveying roller table 103, the two sides of the feeding conveying roller table 103 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com