Strip steel shearing machine

A shearing machine and strip steel technology, which is applied to shearing devices, shearing machine equipment, accessories of shearing machines, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

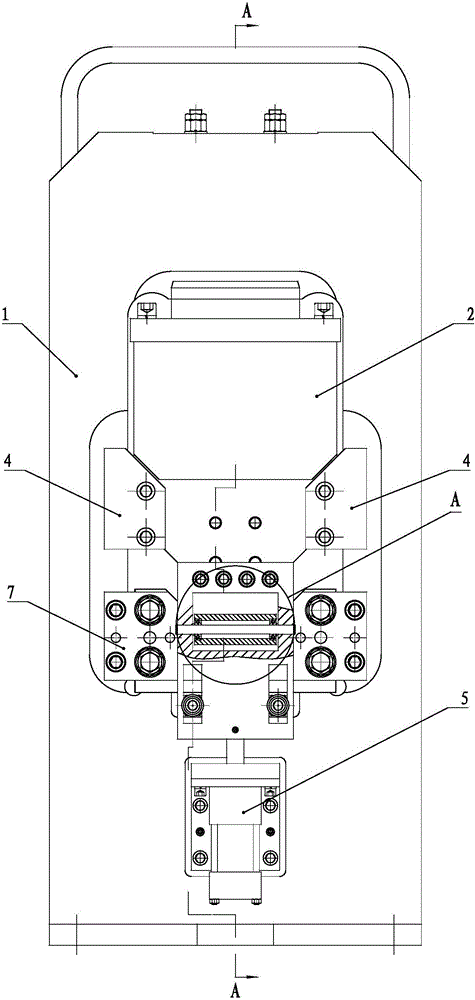

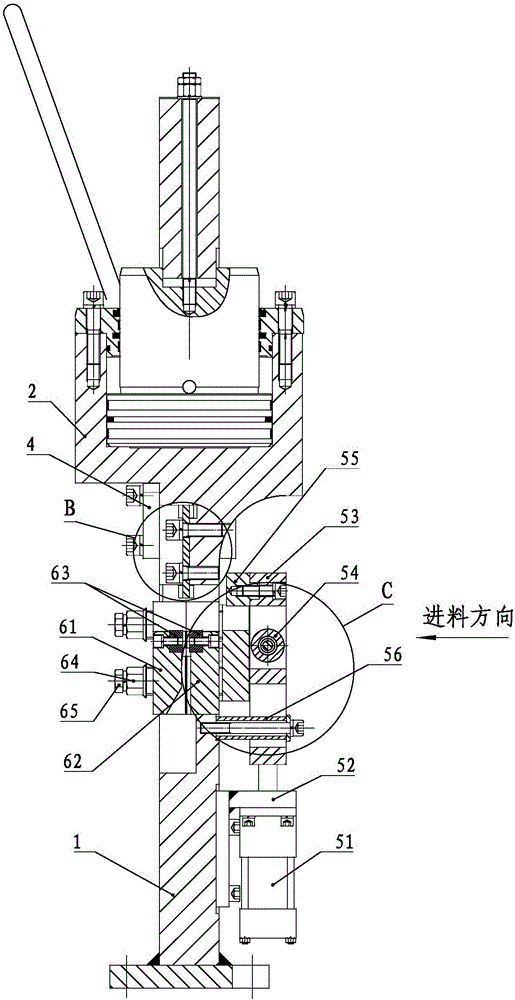

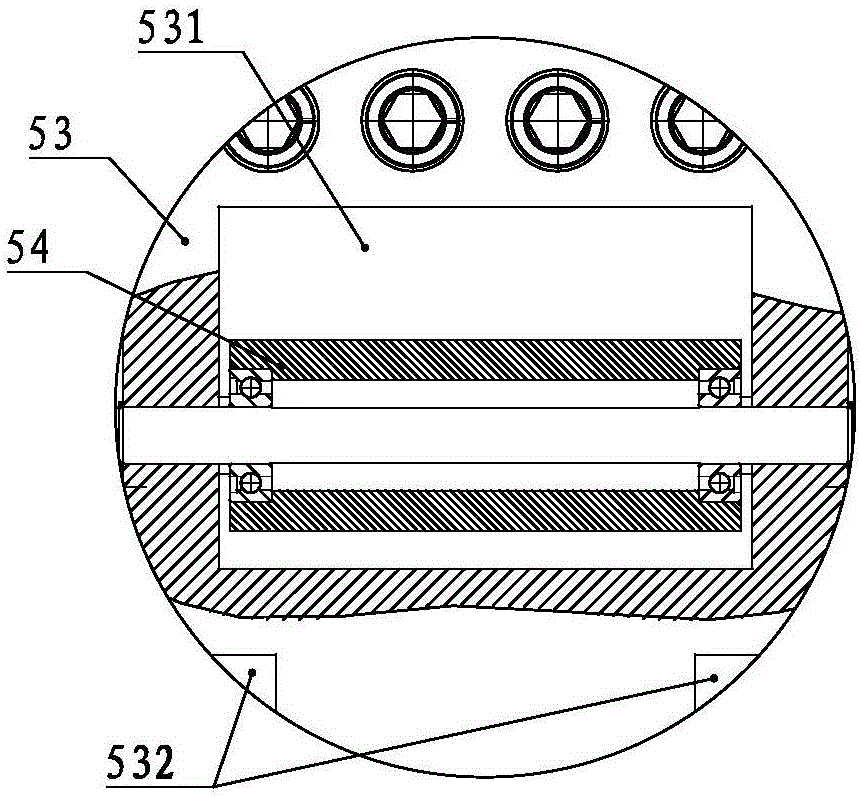

[0037] Such as figure 1 and Figure 6 As shown, the strip steel shearing machine includes a fuselage body 1, the fuselage body 1 is provided with a first through hole that allows the strip steel to pass through, and the inside of the first through hole is set There is a shearing oil cylinder 2, and the piston rod of the shearing oil cylinder 2 faces upwards, the piston rod of the shearing oil cylinder 2 is fixedly connected with the fuselage frame body 1, and the cylinder of the shearing oil cylinder 2 The lower end of the body is fixedly connected with an upper knife 3 by bolts. In order to prevent relative rotation between the cylinder body and the piston rod of the shearing cylinder 2 during the work, thereby affecting the positional accuracy of the upper knife 3 installed on the cylinder body of the shearing cylinder 2, the shearing cylinder 2 An anti-rotation pressing plate 4 is arranged between the cylinder block and the fuselage frame body 1 , and the anti-rotation pr...

Embodiment 2

[0043] Such as Figure 12 As shown, the lower knife part 6 includes a rear knife box 62 and a lower knife 63. The lower knife 63 is one piece and is installed on the rear knife box 62. The rest of the structure is the same as that of the first embodiment. This embodiment is only applicable to the situation that the incision is a straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com