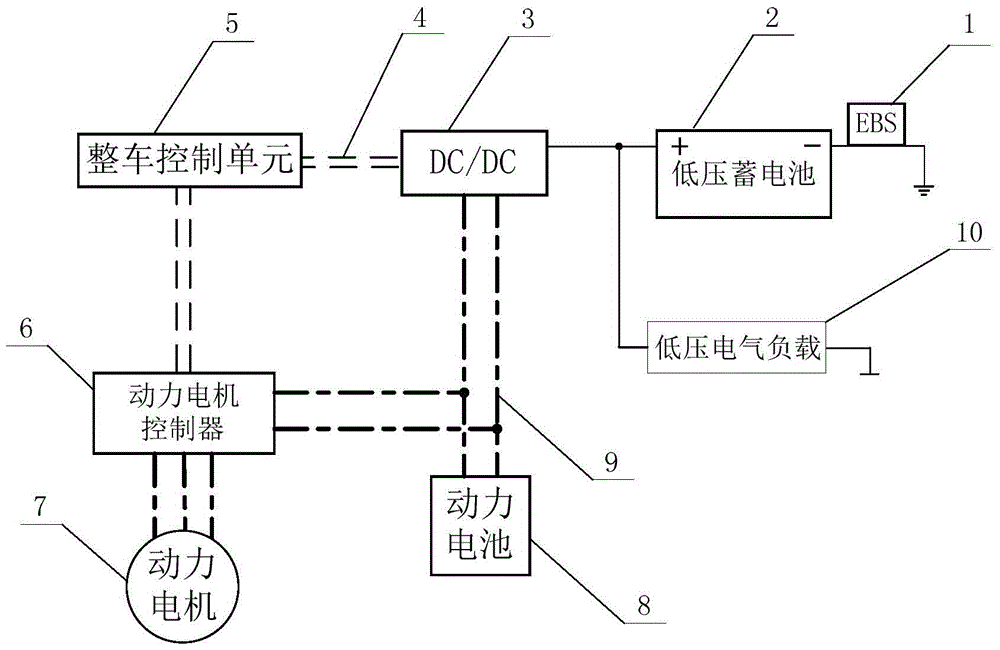

Control method for low-voltage power source management system of new-energy vehicle

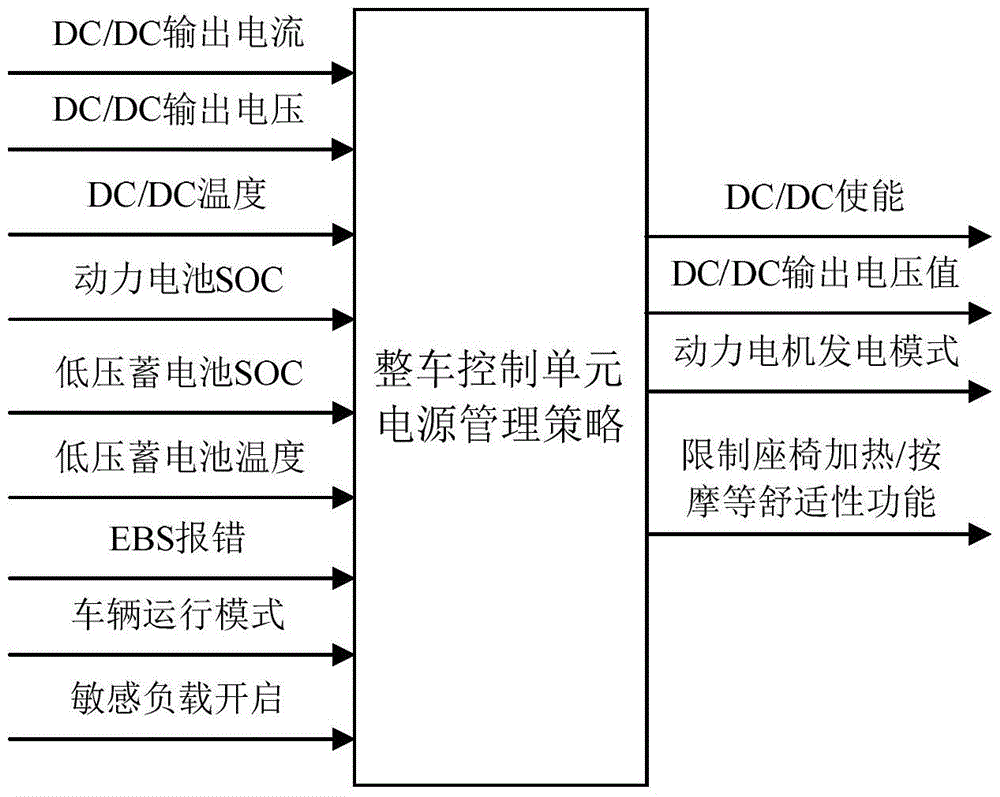

A technology of power management system and low-voltage power supply, which is applied in the direction of battery/fuel cell control device, control device, electric vehicle charging technology, etc., can solve the problems of energy loss, low energy conversion rate, low braking energy recovery rate, etc., and achieve Effects of improving mileage, increasing workload, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The control method in static charging mode (see Figure 4 ) contains the following steps:

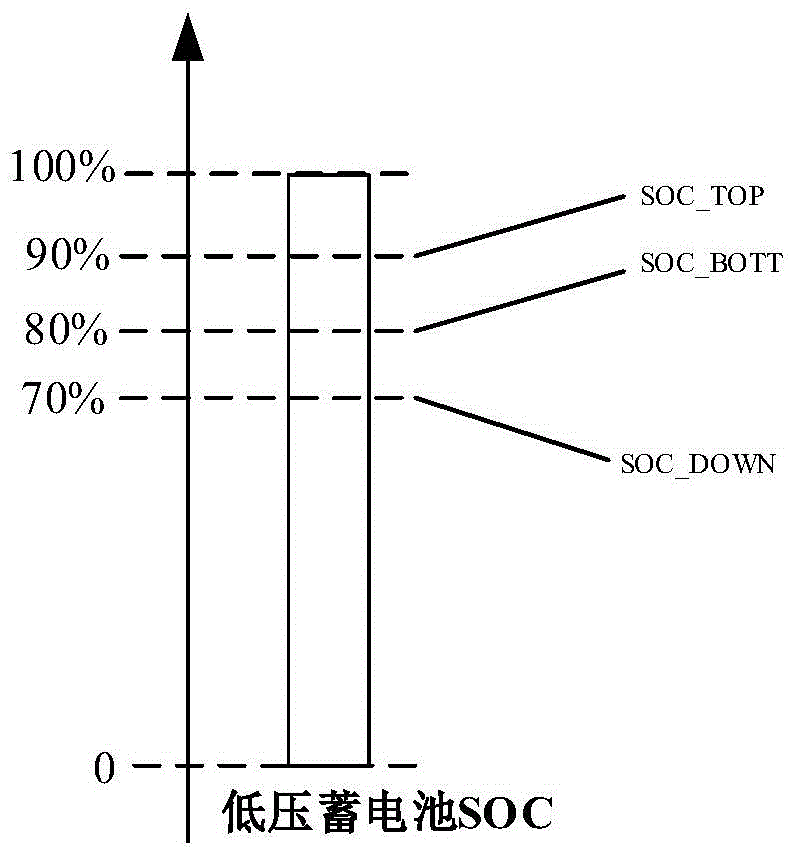

[0049] S41: In the static charging mode, the HCU first judges the SOC of the low-voltage battery, and if the SOC of the battery is 75%, go to step S42;

[0050] S42: The HCU controls the DC / DC output voltage to be 15.5V, charges the low-voltage battery until the SOC of the low-voltage battery reaches 80%, and then executes step S43;

[0051] S43: HCU controls the DC / DC output voltage to be 14.5V;

Embodiment 2

[0053] Control method in Key-on mode (see Figure 5 ) contains the following steps:

[0054] S51: When the vehicle key enters the on gear, the HCU first judges the SOC of the low-voltage battery, and if the SOC of the battery is 70%, execute S52;

[0055] S52: The HCU controls the DC / DC output voltage to be 15.5V, charges the low-voltage battery until the SOC of the battery reaches 80%, and then executes step S53;

[0056] S53: The HCU controls the DC / DC output voltage to be 14.5V, charges the low-voltage battery until the SOC of the battery reaches 90%, and then executes step S54;

[0057] S54: HCU controls the DC / DC output voltage to be 12.7V, discharges the battery until the SOC of the battery reaches 80%, and then executes step S53;

Embodiment 3

[0059] Control method in Key-on mode (see Figure 5 ) contains the following steps:

[0060] S51: When the vehicle key enters the on gear, the HCU first judges the SOC of the low-voltage battery, and if the SOC of the battery is 85%, execute S53;

[0061] S53: The HCU controls the DC / DC output voltage to be 14.5V, charges the low-voltage battery until the SOC of the battery reaches 90%, and then executes step S54;

[0062] S54: HCU controls the DC / DC output voltage to be 12.7V, discharges the battery until the SOC of the battery reaches 80%, and then executes step S53;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com